Intelligent air automatic sampler for occupational health

An automatic sampling and hygienic technology, applied in the direction of sampling devices, etc., can solve the problems of dust affecting the airtightness of the gas path, corroding the solenoid valve, and easy cross-contamination of the absorption bottle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

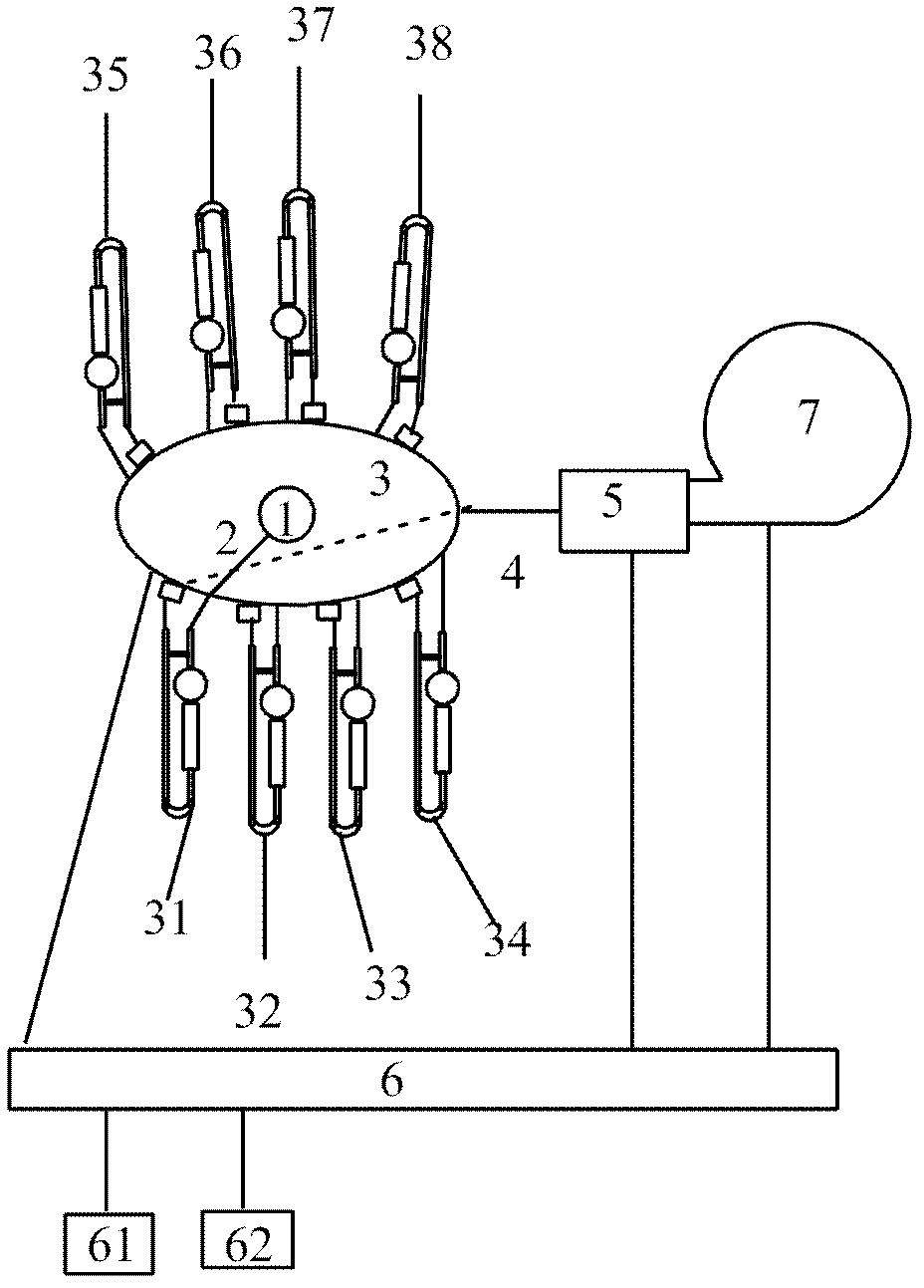

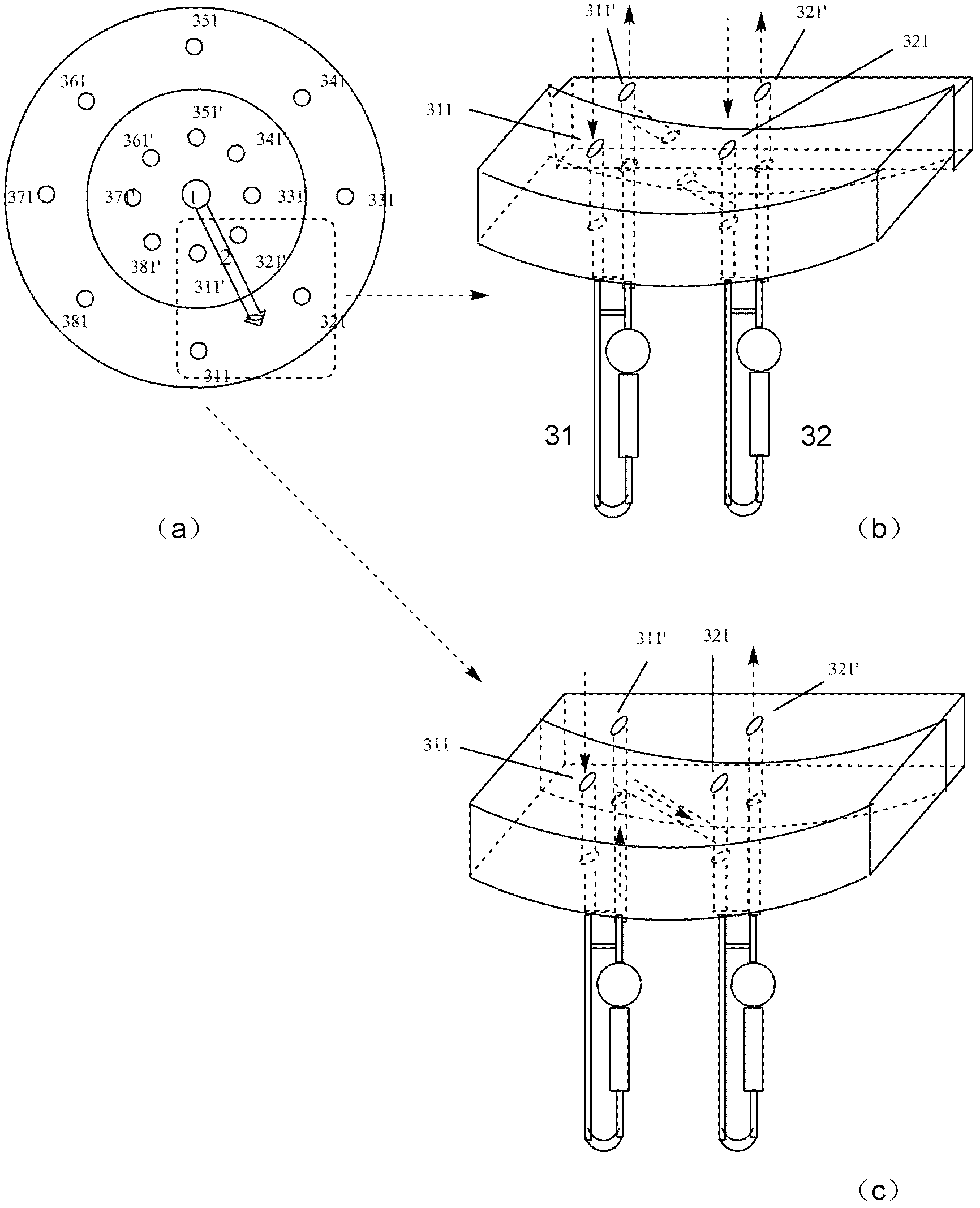

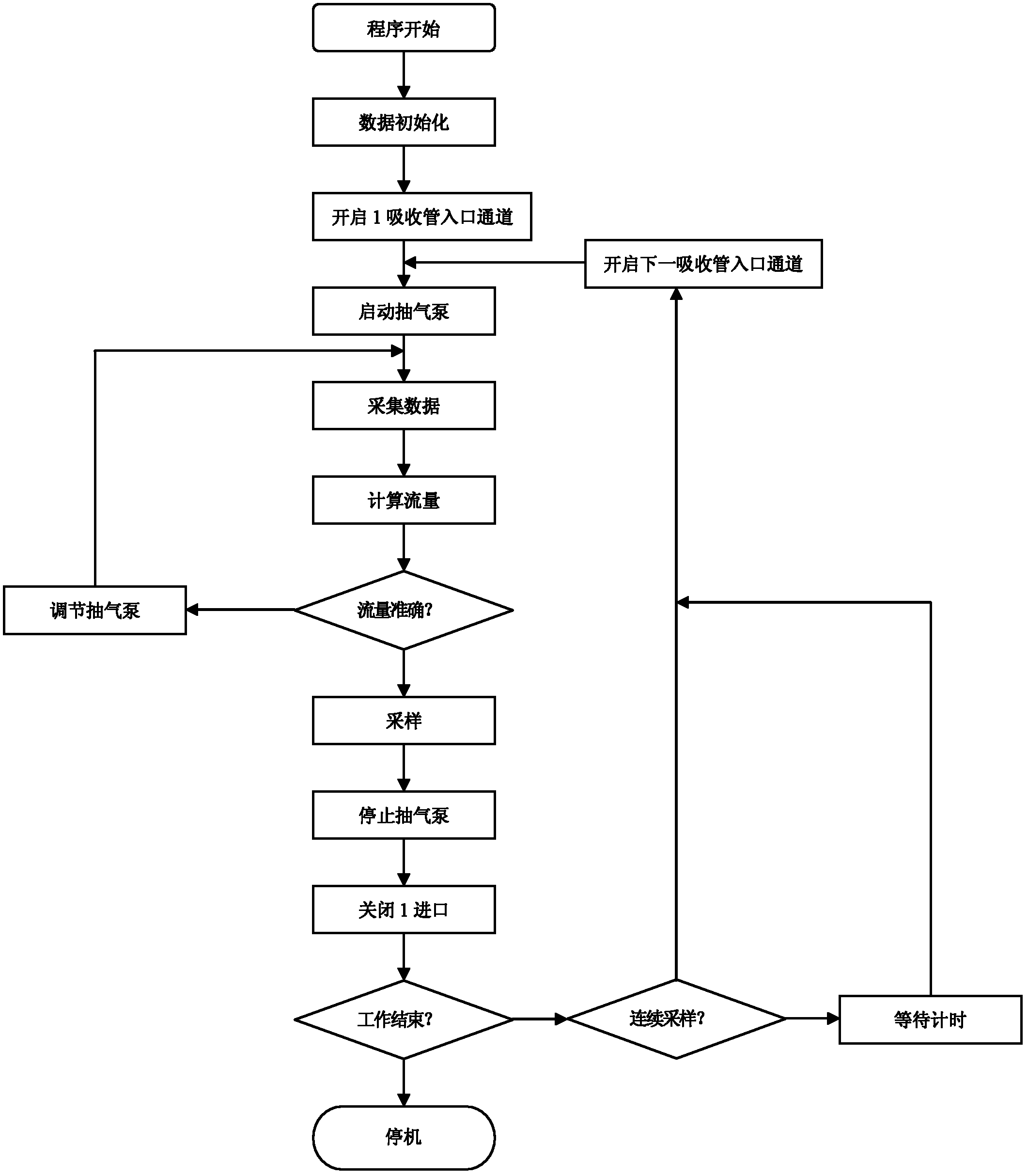

Embodiment 1

[0023]Detect the content of hydrogen chloride in the atmosphere: when working, insert the absorption tube into the air inlet and air outlet on the control valve 3 in sequence, and under the control of the single-chip microcomputer 6, the program starts to run. After the data initialization is completed, the air inlet connecting pipe 2 is automatically switched To (the switching process is completed by the single-chip microcomputer by controlling the roller and the forward and reverse motor inside the control valve 3) the air inlet 311, the air outlet connecting pipe 4 is automatically switched to the air outlet 311 ', and the single-chip microcomputer 6 controls the opening of the air inlet 311 to start The air pump 7 (JH-606 electric air pump) collects data, while collecting atmospheric samples, the flow sensor 5 (JKY / 4008-50SLpm / 314724 flow sensor) is used to calculate and control the sampling flow rate to 0.5L / min, after 15 minutes of sample collection , stop the air pump 7,...

Embodiment 2

[0025] Detection of NH in the atmosphere 3 Content: when working, insert the absorbing pipe into the air inlet and air outlet on the control valve 3 in turn, under the control of the single-chip microcomputer 6, the air inlet connecting pipe 2 is not connected with the air inlet 321, 341, 361, 381, The air inlet holes 321, 341, 361, 381 are connected to the air outlet holes 311', 331', 351' and 371' respectively, and the connection between the air outlet holes 311', 331', 351' and 371' to the atmosphere is closed. The program starts to run, and after the data initialization is completed, the air inlet connecting pipe 2 automatically switches to the air inlet 311, the air outlet connecting pipe 4 automatically switches to the air outlet 321', and the control valve 3 controls the opening of the air inlet 311 and the air outlet 321' to absorb The pipe 31 and the absorption pipe 32 are connected in series, start the suction pump 7 to collect data, and use the flow sensor 5 to calc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com