Testing apparatus for internal corrosion of circulating multiphase flow undulating pipeline

An experimental device and multiphase flow technology, which are applied in the field of corrosion experimental devices in undulating pipelines of circulating multiphase flow, can solve the problem of not considering the corrosion parameter measurement of corrosive gas recycling, not considering the influence of corrosion gas recycling, and unsuitable for corrosion. Corrosion experiments of dry gas or wet gas systems, etc., to save experimental costs, save experimental time, and improve accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

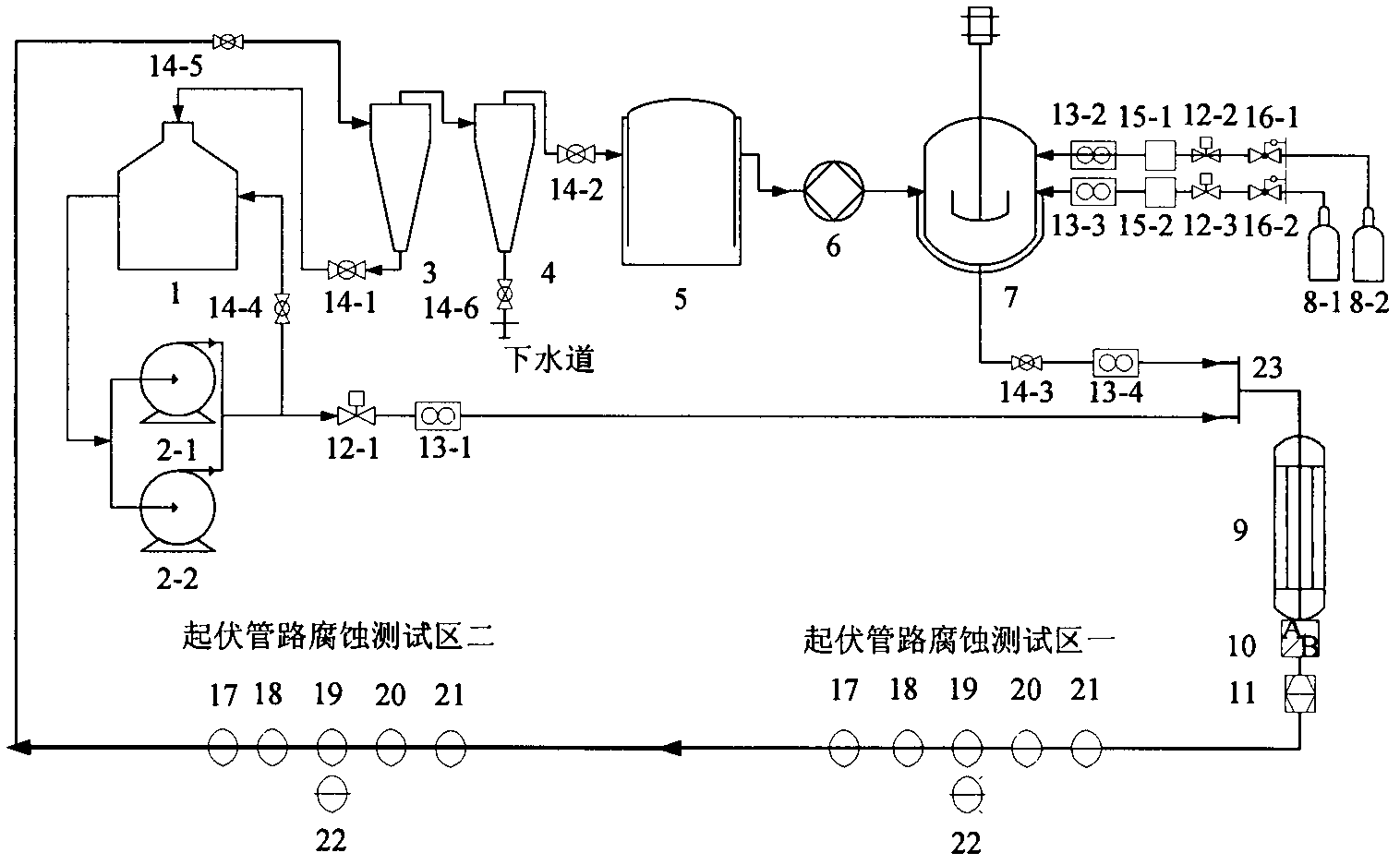

[0031] In conjunction with accompanying drawing, the present invention is further described:

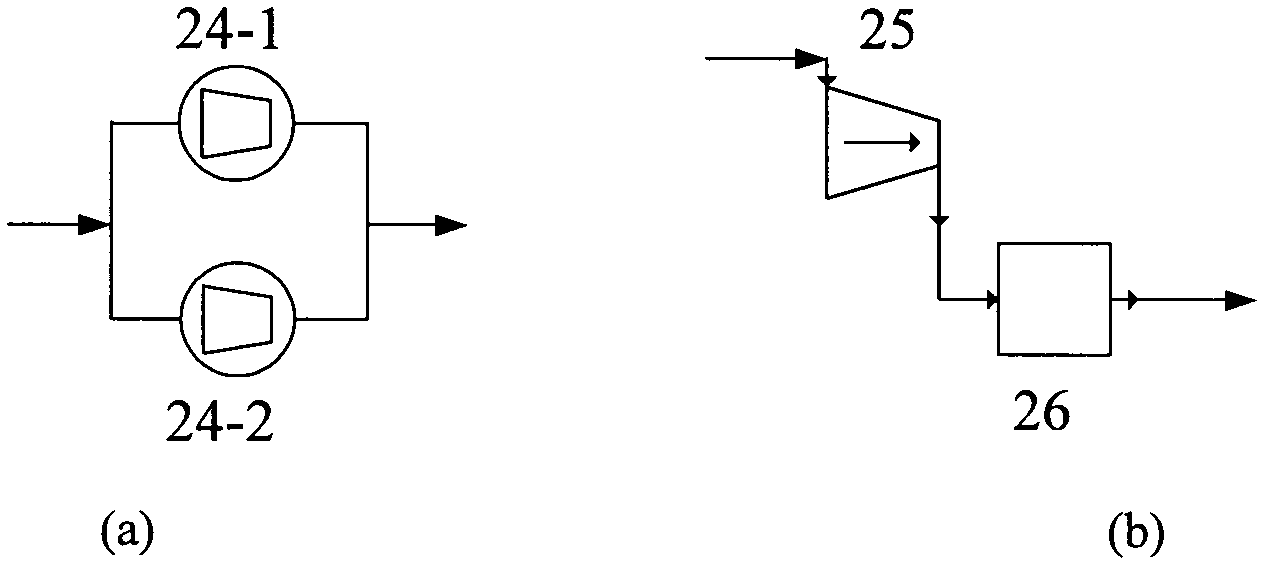

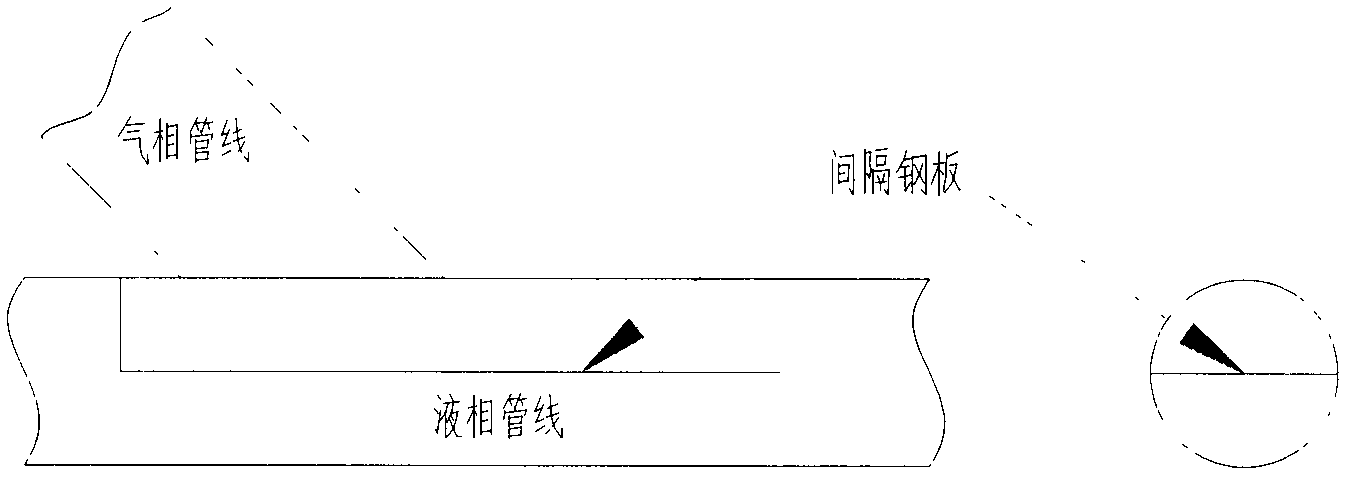

[0032] Such as figure 1 As shown, the experimental device of the present invention is mainly composed of a gas-phase closed circulation system, a liquid-phase closed circulation system, a gas-liquid two-phase separation system, a temperature control system, a multiphase flow fluctuating pipeline system, an online corrosion test system and various control valves. The gas-phase closed circulation system consists of a low-pressure gas storage tank 5, a circulating gas booster pump group 6, a high-pressure gas storage tank 7, a high-pressure gas cylinder 8 and control valves 12-2, 12-3, 13-2, 13-3, 15- 1. Composed of 15-2, 16-1 and 16-2; the liquid-phase closed circulation system is composed of liquid storage tank 1, corrosion-resistant centrifugal pump unit 2 and control valves 12-1, 13-1, 14-4; gas-liquid The two-phase separation system consists of a primary gas-liquid separator 3, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com