Device for testing heat resistance of nonmetal material

A non-metallic material and testing device technology, applied in the field of material testing devices, can solve the problems of no quantitative or qualitative results, single test function, and inability to accurately grasp the burning time and degree of non-metallic materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

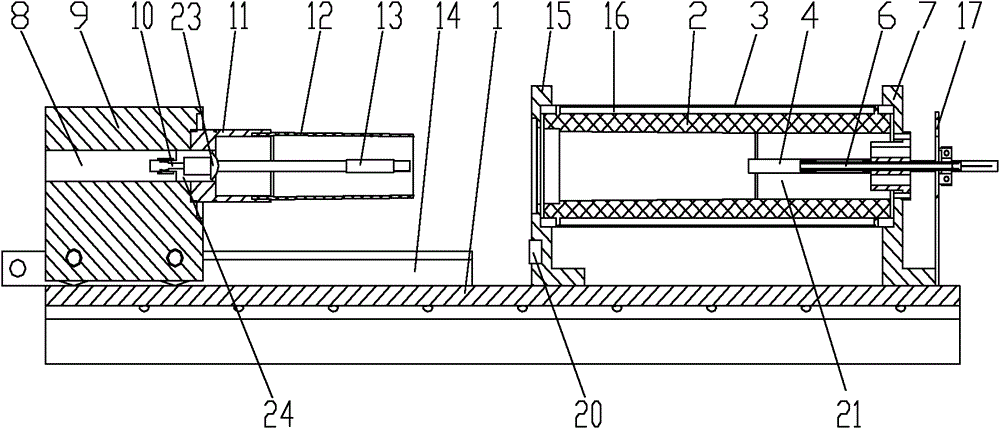

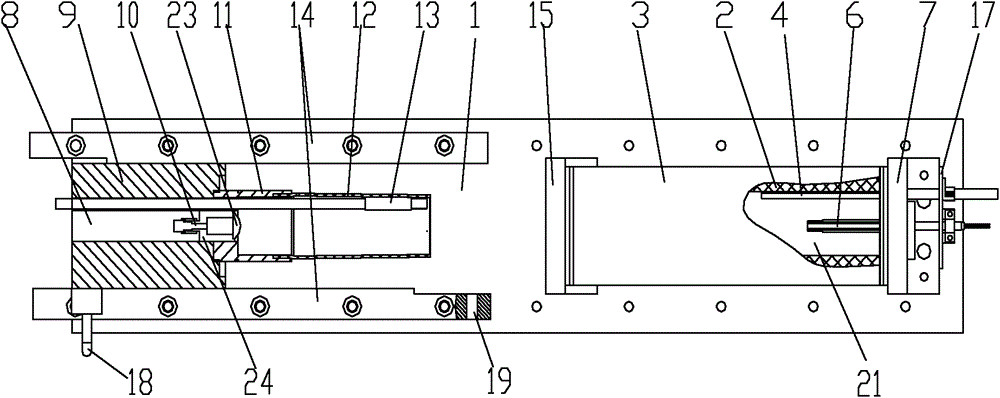

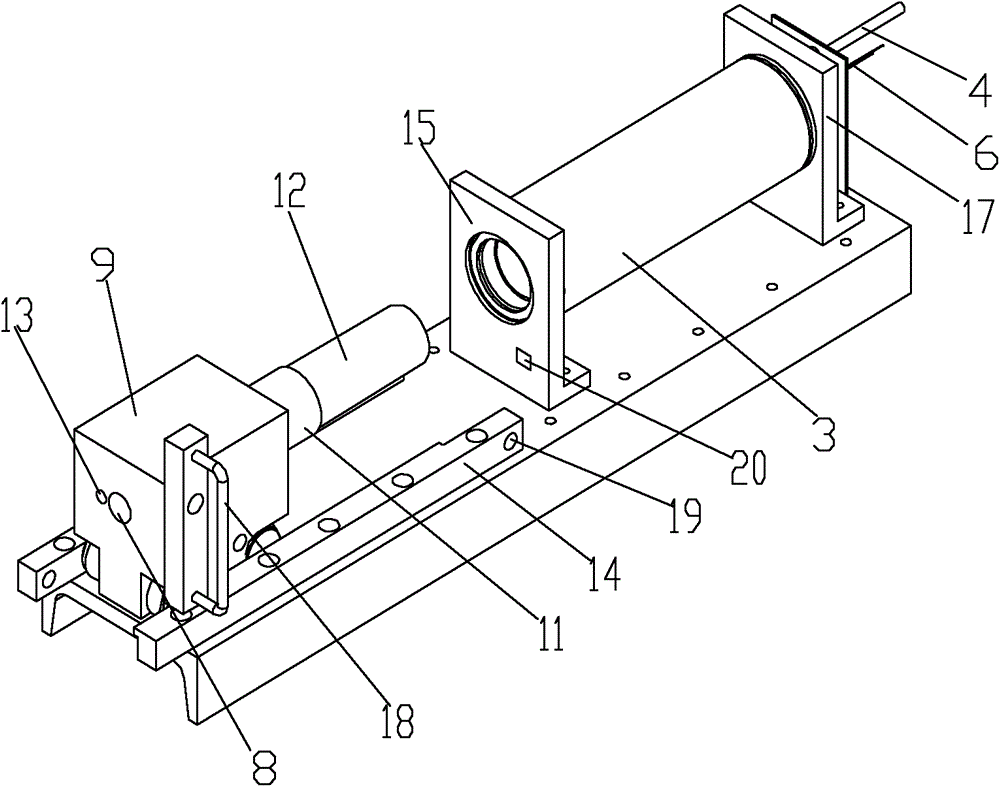

[0030] figure 1 It is a schematic cross-sectional view of the structure of the present invention, figure 2 It is a top view of the present invention, image 3 It is a three-dimensional structure diagram of the present invention, Figure 4 It is a block diagram of the control principle of the present invention, as shown in the figure: the non-metallic material heat resistance testing device of this embodiment includes a base 1, a clamping mechanism, an electric heating device 2, a data acquisition system and a central processing unit 22;

[0031] The clamping mechanism includes a slider 9 and a clamping head 11, the slider 9 can be locked and slidably arranged on the base 1, and the clamping head 11 is fixedly arranged on the slider 9 along the sliding direction of the slider 9 And it is used to clamp the workpiece 12 to be tested; the clamping head 11 can adopt different structures according to the structure of the workpiece 12 to be tested. That is to say, the mechanical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com