Tapered bearingless asynchronous motor

An asynchronous motor, bearingless technology, applied in asynchronous induction motors, electrical components, electromechanical devices, etc., to achieve the effects of high critical speed, simple and compact structure, and simplified mechanical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

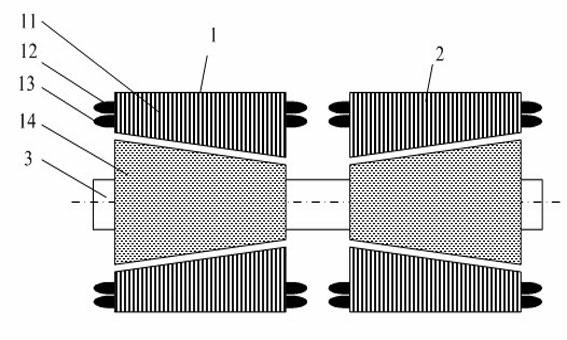

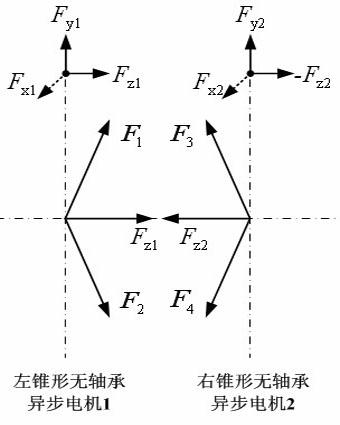

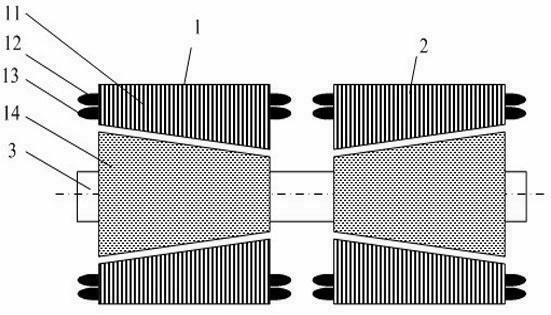

[0018] like figure 1 As shown, the conical bearingless asynchronous motor includes a motor housing and a mechanical shaft 3, and the mechanical shaft 3 passes through the left and right ends of the motor housing. Two identical bearingless asynchronous motors are installed on the left and right ends of the motor housing, namely the left conical bearingless asynchronous motor 1 and the right conical bearingless asynchronous motor 2. Asynchronous motors are connected symmetrically. The left conical bearingless asynchronous motor 1 or the right conical bearingless asynchronous motor 2 is composed of a conical stator 11 , a torque control winding 12 , a suspension force control winding 13 and a conical rotor 14 . The conical stator 11 is formed by laminating electrical silicon steel sheets. On the conical stator 11, a certain number of stator slots are opened in the axial direction. In the radial direction, each stator slot is divided into inner and outer layers. The suspension f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com