Technology and equipment for manufacturing vacuum heat insulation vessel

A technology for vacuum insulation and manufacturing equipment, which is applied in the direction of manufacturing tools, metal processing equipment, drinking vessels, etc. It can solve the problems of easy air leakage, impact on the service life of the thermos cup, and the shape limitation of the thermos cup, so as to prolong the heat preservation time and seal The effect of better performance and longer service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

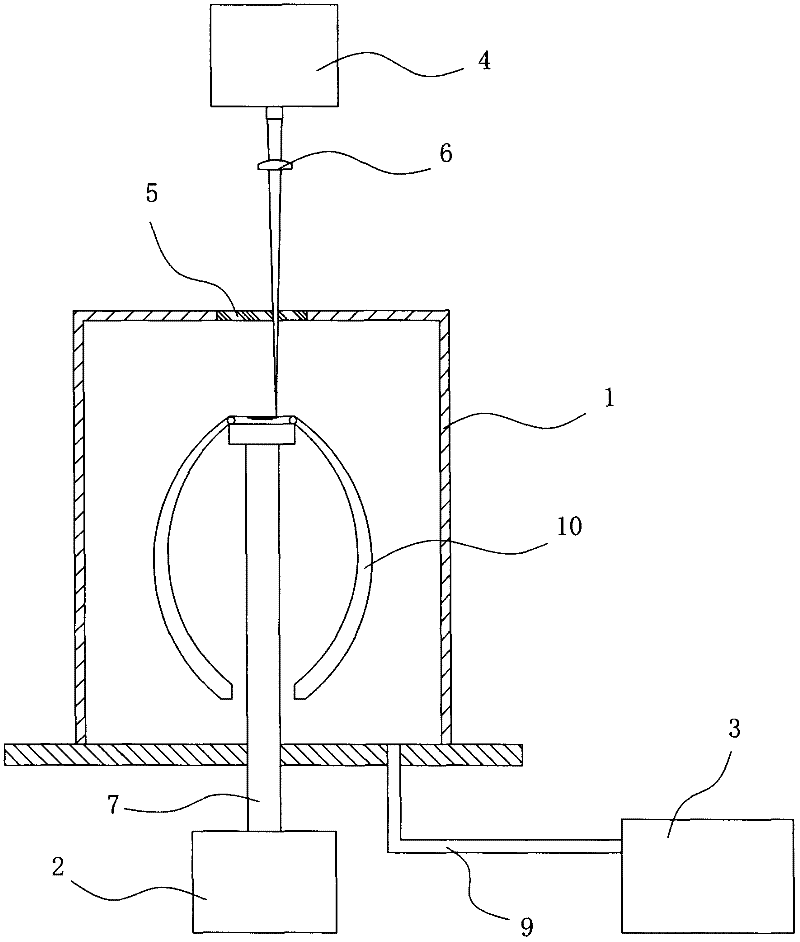

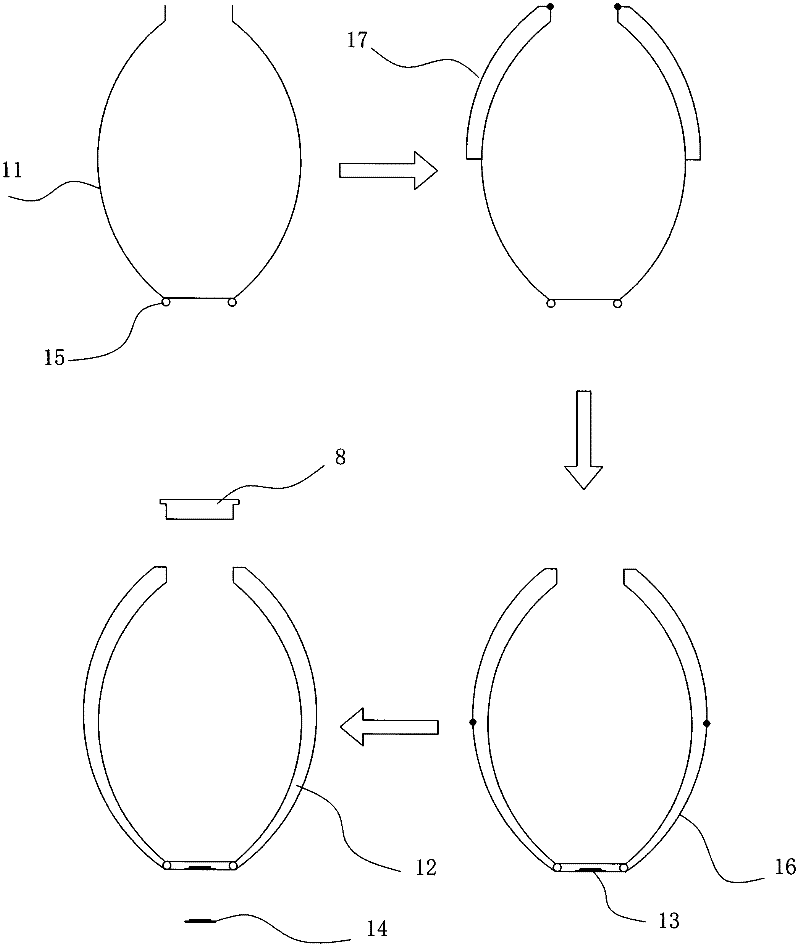

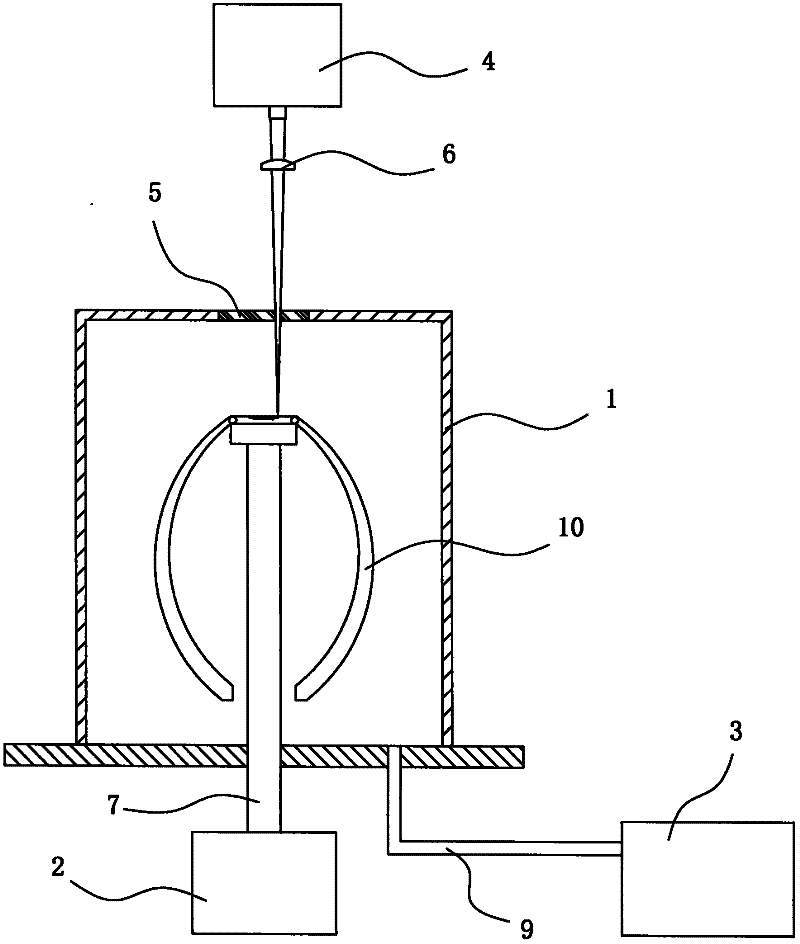

[0029] Embodiment one: see figure 1 , 2 As shown, a manufacturing equipment for vacuum heat preservation vessels includes a vacuum chamber 1, a turntable 2, a vacuum pump 3 and a laser welding device 4. The vacuum chamber 1 is provided with a cavity for accommodating a vessel to be processed, and a laser window is provided on the top of the vacuum chamber 1. 5. There is a focusing lens 6 between the laser welding equipment 4 and the vacuum chamber 1, the emitting end of the laser welding equipment 4 corresponds to the laser window 5, and the turntable 2 is located below the vacuum chamber 1 , the turntable 2 is composed of a rotating motor and the support rod 7 connected to the output shaft of the rotating motor, the top of the support rod 7 matches the inner bottom surface of the vessel to be processed, and the support rod 7 extends into the vacuum In the chamber 1, the vessel to be processed is buckled upside down on the support rod 7, and the position of the opening to be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com