Wheat washer capable of feeding from bottom

A bottom-feeding and wheat washing machine technology, which is applied in application, grain processing, grain milling, etc., can solve the problems of unqualified flour moisture quality indicators, excessive dust and organic impurities, and increased sewage discharge, etc., to achieve elimination once Excessive flooding, clean and hygienic working environment, and the effect of eliminating foam in sewage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

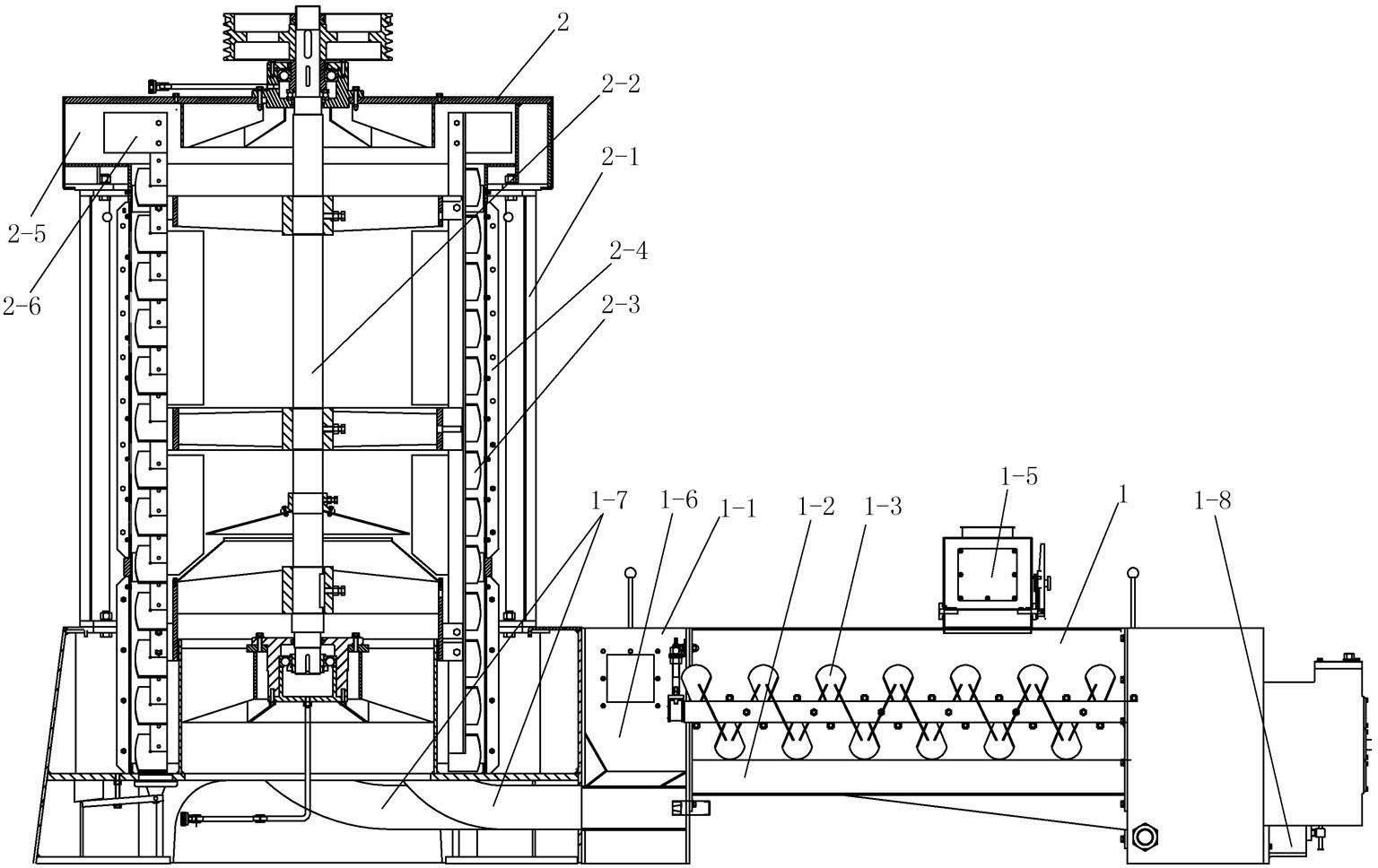

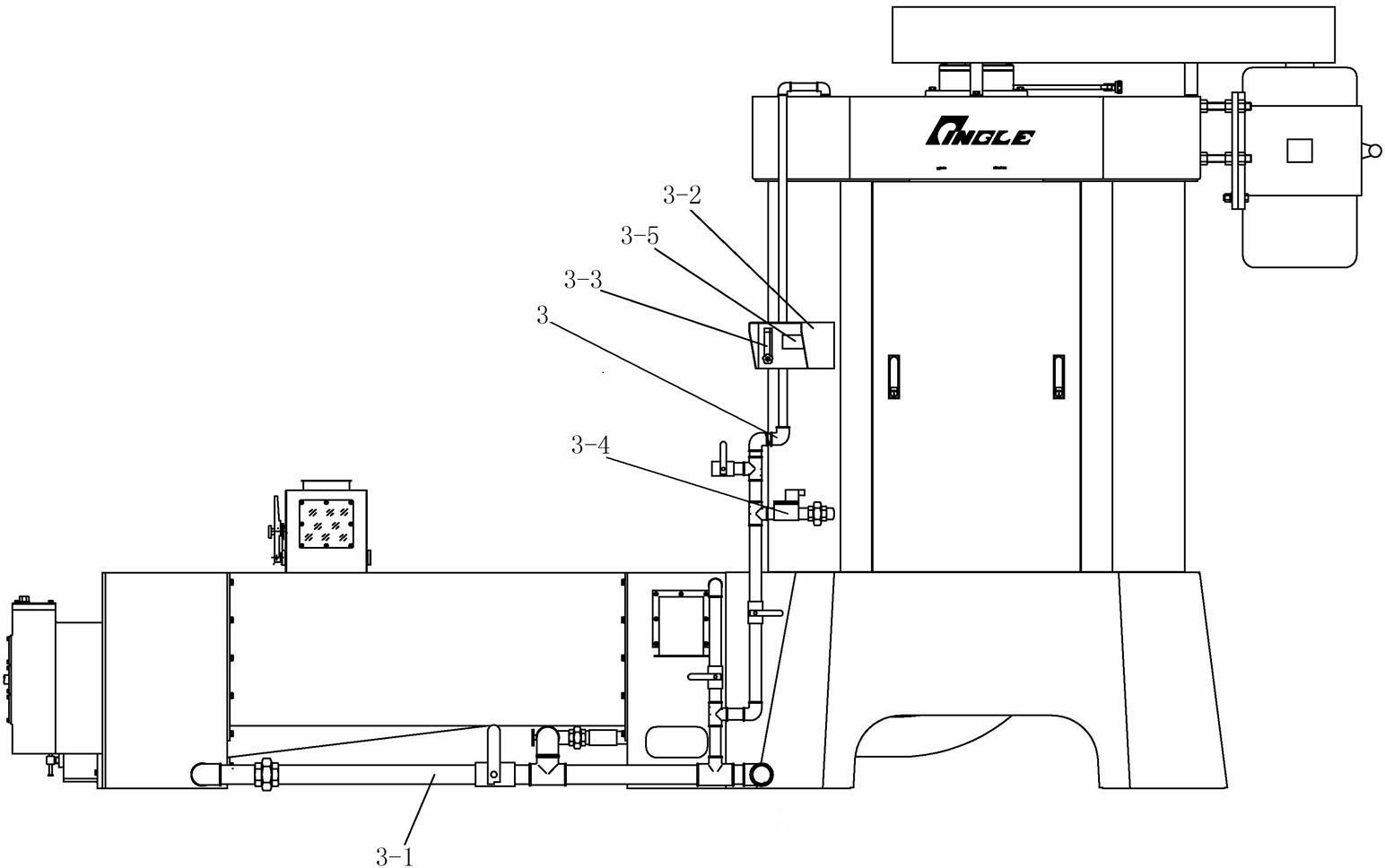

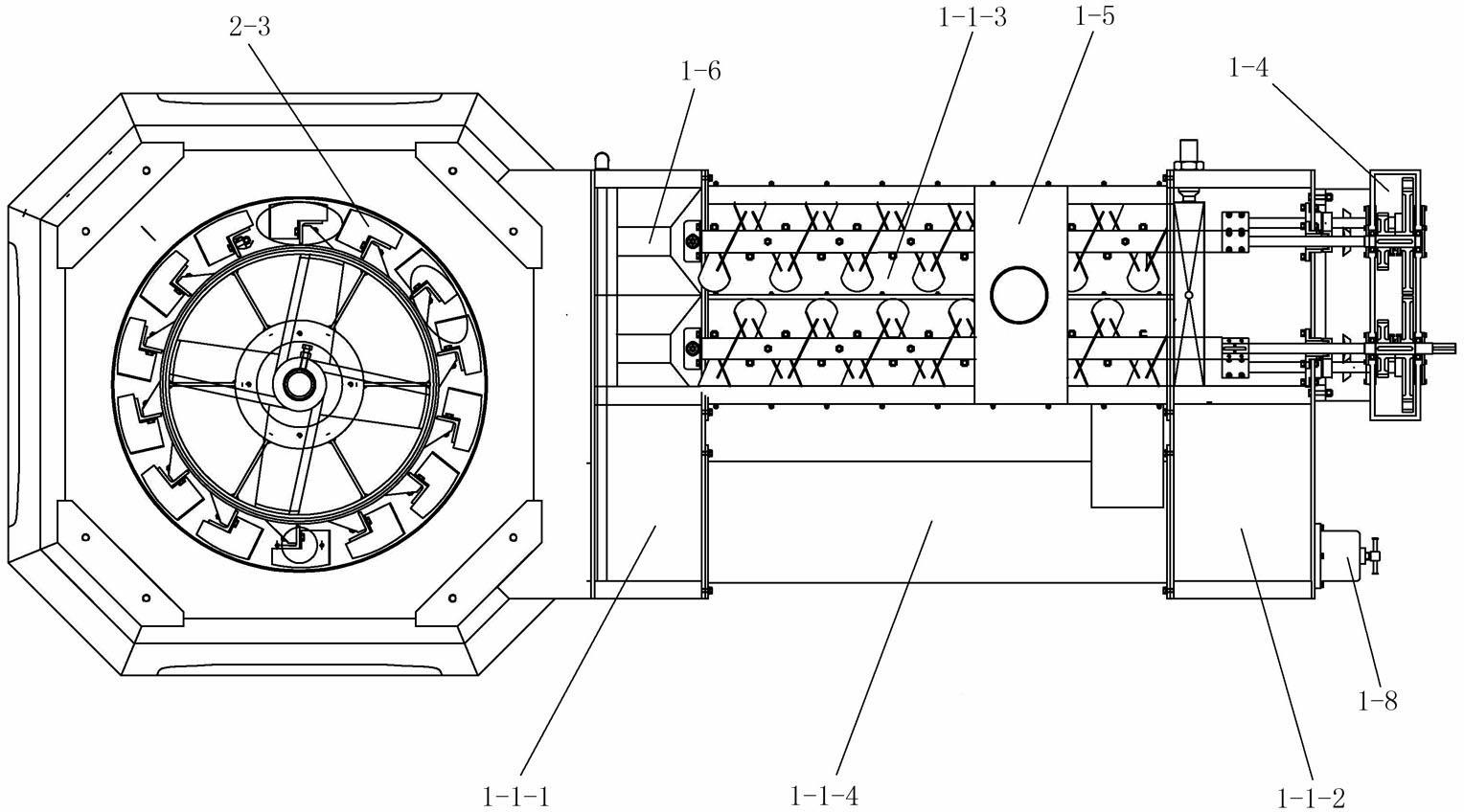

[0015] as attached figure 1 , 2 , 3, and 4, the present invention includes a desanding device 1, a drying tower 2 connected to the desanding device 1, and a timing spraying system 3.

[0016] The desanding device 1 of the present invention consists of a circulating water tank shell 1-1, a sand auger 1-2, a wheat auger 1-3 and a transmission for driving the sand auger 1-2 and the wheat auger 1-3. The tank 1-4 is composed of the circulating water tank 1-1 consisting of the circulating water tank front shell 1-1-1, the circulating water tank rear shell 1-1-2 and the circulating water tank front shell 1-1-1 and the circulating water tank rear shell 1-1-2 consists of a wheat washing tank 1-1-3 and a return tank 1-1-4, and the sand auger 1-2 and wheat auger 1-3 are arranged in the wheat washing tank 1-1-3 Inside, the upper end of the wheat washing tank 1-1-3 is provided with a feed hopper 1-5, and the rear shell 1-1-2 of the circulating water tank is provided with a A funnel-shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com