Preparation method for simulated surfaces

A surface topography, metal surface technology, applied in welding equipment, manufacturing tools, laser welding equipment and other directions, can solve the problems of insufficient precision control, low processing efficiency, etc., to achieve high processing efficiency, improve fatigue resistance and stress corrosion resistance. , The effect of easy control of surface pit morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

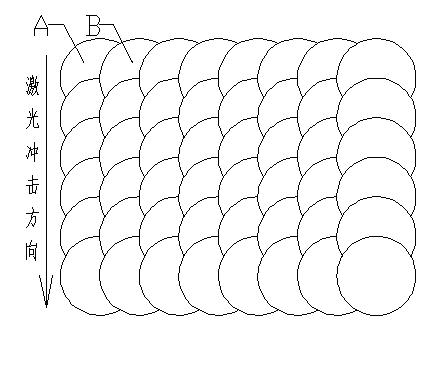

[0020] Hereinafter, a description will be given by taking laser shock forming a superimposed (fish-scale) bionic metal surface as an example.

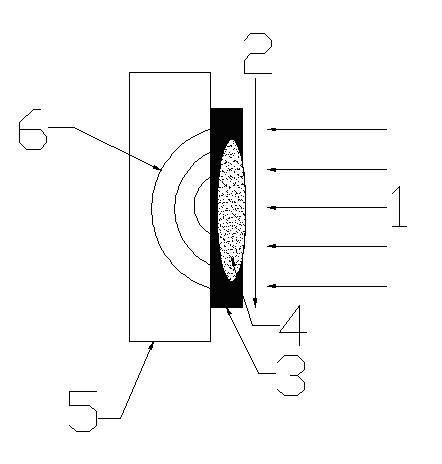

[0021] First, pre-treat the surface of the metal 5 to be processed to make the surface as smooth as possible. Then set the wavelength, pulse width, pulse energy, and spot radius parameters of the high-power laser according to the required special surface topography. In this example, the wavelength can be set to 1.054μm, the pulse width is 20.1ns, and the pulse energy is 36J. Then program the running path of the CNC table according to the distribution of the special surface topography; and paste aluminum foil 3 on the surface of the metal 5 to be impacted. , Attach a constraining layer outside the aluminum foil. In this example, water 2 is used as the constraining layer. Finally, the metal 5 to be impacted is fixed on the numerical control workbench with a clamp, and the high-power laser is controlled to emit a laser beam 1 to perform la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com