Processing method for manufacturing laminated wood board core board from spruce branch tips and laminated wood board

A technology of blockboard and processing method, which is applied in the direction of joining of wooden veneers, manufacturing tools, and wood processing utensils, etc., can solve problems such as low yield rate, and achieve the effect of low price, low cost, and meeting the needs of the board.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

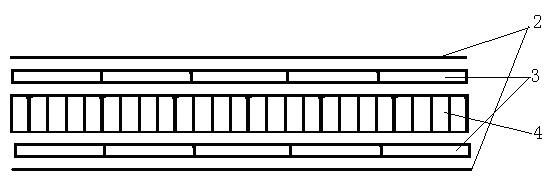

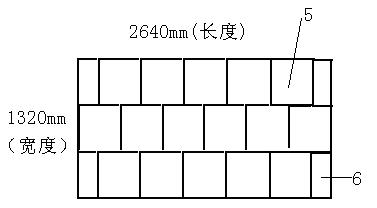

[0025] The specific steps of the processing method of utilizing fir tip to manufacture blockboard core board and blockboard are:

[0026] Step 1: Clean up the bark, branches and other sundries from the collected fir tips in time, and cut them into fir sticks with a length of 0.5 meters by cross-cut sawing;

[0027] Step 2: Necessarily classify the truncated fir sticks according to the diameter of the small head. The sorted fir sticks are sent to the wood drying kiln for drying. The drying temperature is 100-120°C and the drying time is 15-30 hours. The moisture content is controlled at 8~10%;

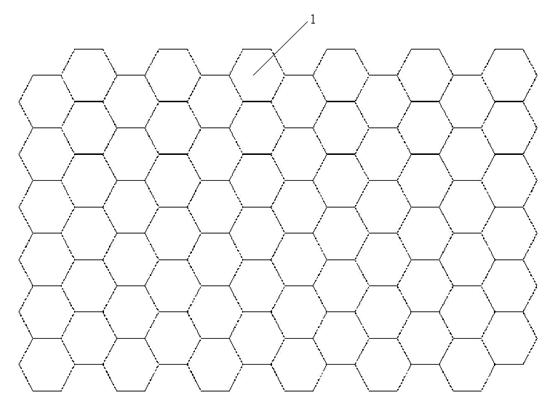

[0028] Step 3: send the dried Chinese fir sticks into a wood forming milling machine to be processed into a regular hexagonal prism, and the diameter of the inner truncated circle of the regular hexagonal prism is set at 2mm, 4mm or 6mm;

[0029] Step 4: Take out the regular hexagonal prism with the same inner truncated diameter, and apply Thiel floor glue, the amount of glue is 200-26...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com