Method for preparing zinc oxide varistors while increasing potential gradient and nonlinear coefficient

A technology of nonlinear coefficient and potential gradient, which is applied in the field of zinc oxide varistors to increase the potential gradient and nonlinear coefficient at the same time, and can solve problems such as the decrease of nonlinear coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] The sintered material with code G1-10 was prepared by chemical precipitation method, and its components are listed in Table 1.

[0061] Table 1. The molar ratio of each component of the sintered material (with 1mol of ZnO)

[0062] Component (mol%)

Bi 2 o 3

MnO 2

co 2 o 3

Sb 2 o 3

Y 2 o 3

Ce 2 o 3

SiO 2

B 2 o 3

G1-10

1.50

1.00

1.00

1.00

0.003

0.003

0.50

0.005

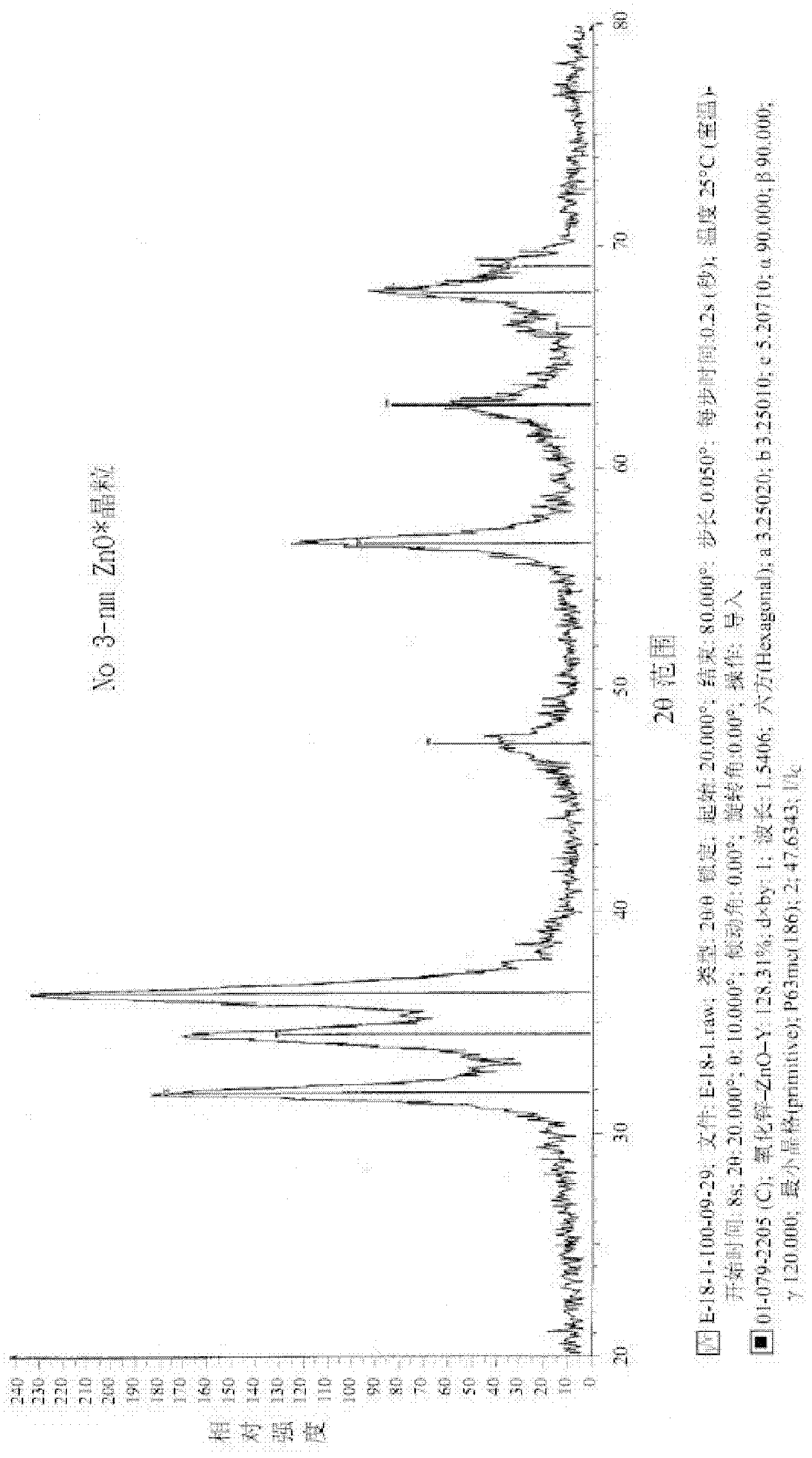

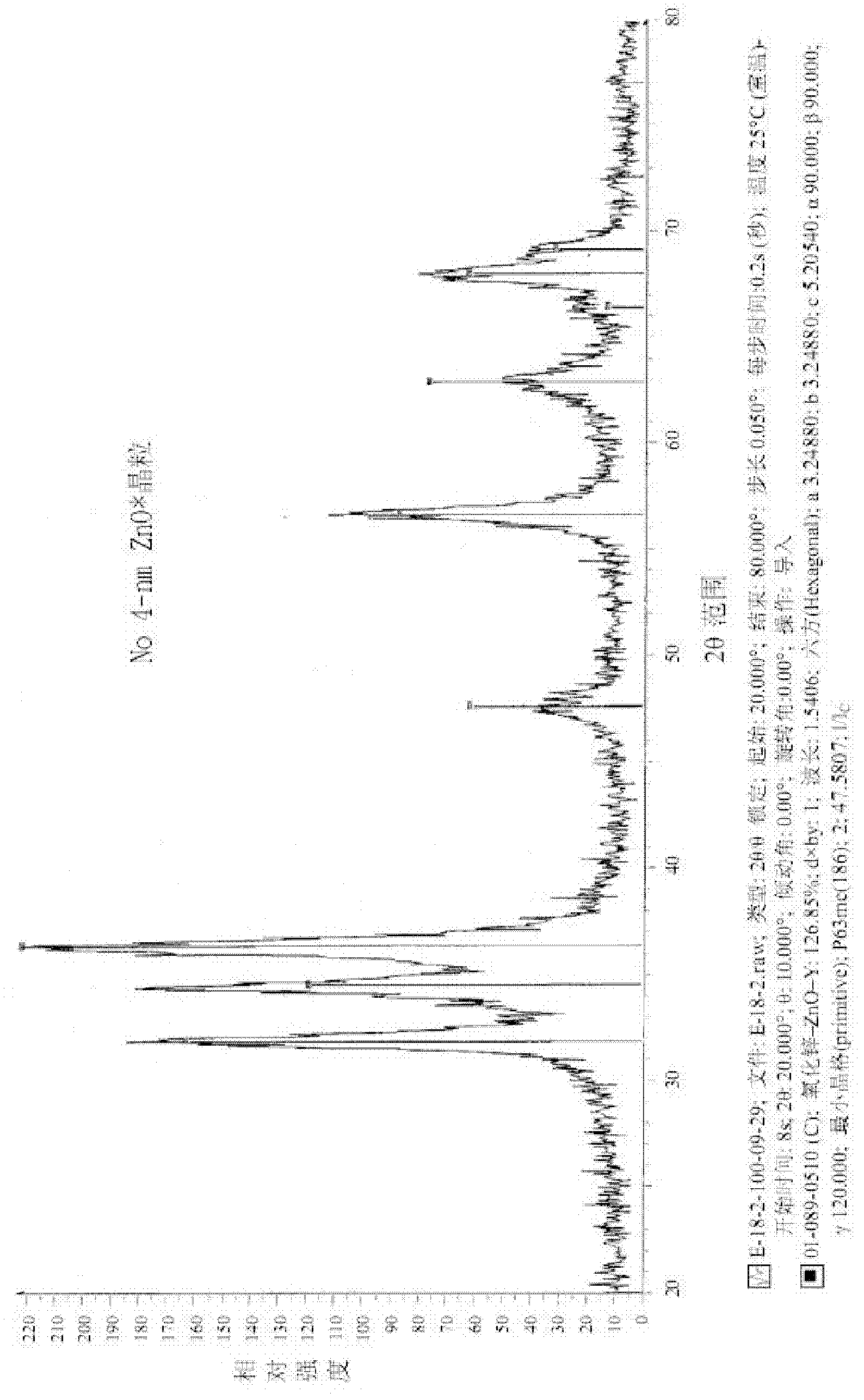

[0063] Preparation of Doped ZnO by Soaking in Doping Ion Solution * The crystal grains, the types and ratios of doped ions are listed in Table 2.

[0064] Table 2. Doped ZnO * Each dopant ion species and molar ratio in the grain (ZnO is 1mol)

sn

Si

B

Al

Ratio (mol%)

0.60

0.10

1.00

0.015

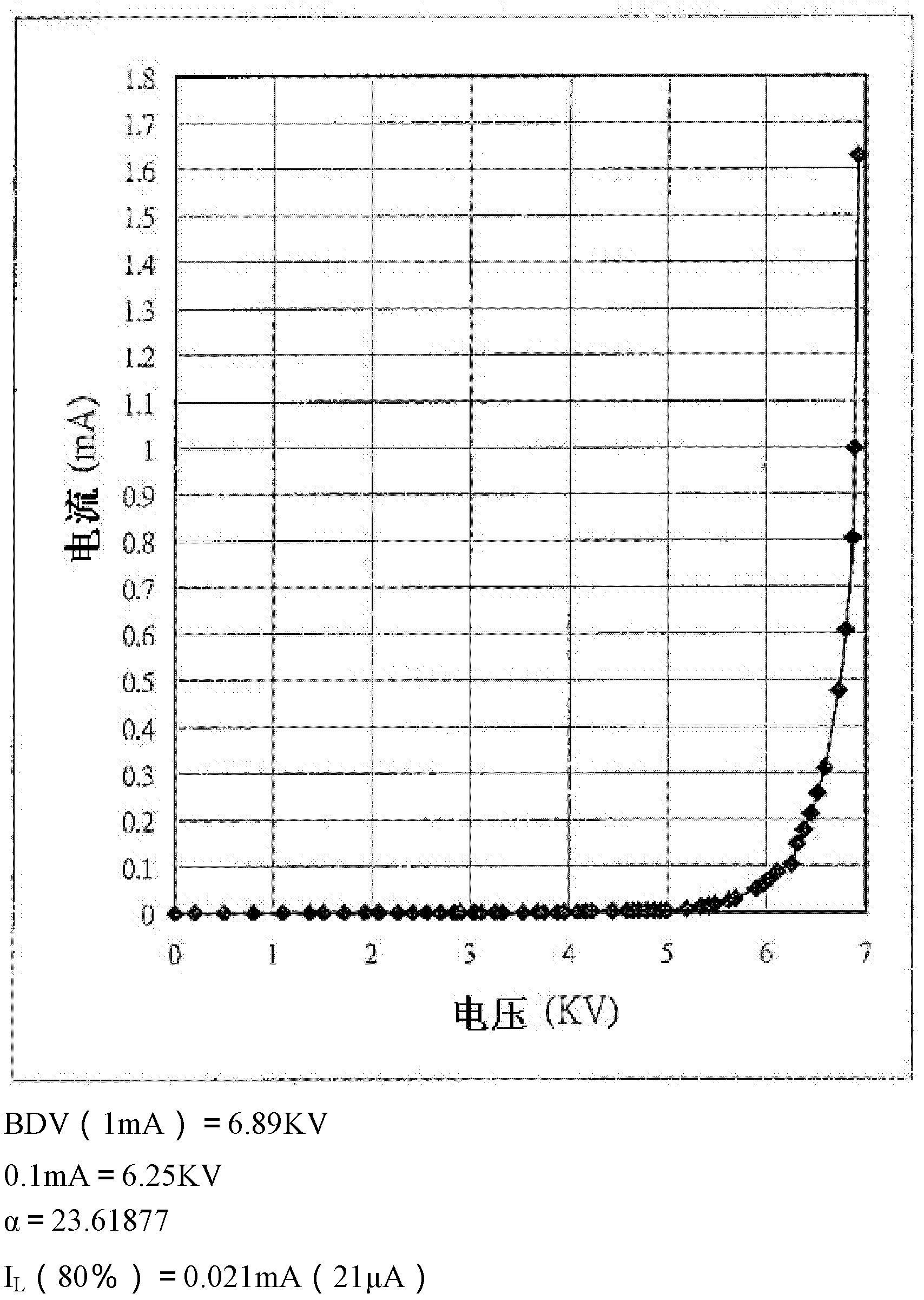

[0066] Will be doped with ZnO * After mixing the grains and G1-10 sinter powder evenly, use 1000k...

Embodiment 2

[0070] The zinc oxide grain samples listed in Table 5 doped with 1 mol% indium (In) ions were prepared by chemical co-precipitation method. The sintered material code-named G1-00 was prepared by chemical co-precipitation method, and its composition and weight ratio are listed in Table 4.

[0071] Table 4. Components of sintered material (wt%)

[0072]

[0073] According to the weight ratio of zinc oxide grain sample: G1-00 sintered material is 100:10 or 100:15 or 100:30, mix evenly, and then use 1000kg / cm 2 The pressure is pressed into a disc, and then sintered at a sintering temperature of 1065 ° C for 2 hours, and then coated with silver electrodes at 800 ° C, and a disc type zinc oxide varistor is made. The properties of various zinc oxide varistors were measured respectively, and the results are shown in Table 5.

[0074] It can be seen from Table 5 that when the zinc oxide grains are doped with the same doping ion composition, the pressure-sensitive characteristics o...

Embodiment 3

[0078] Same as Example 1, prepare G1-10 sinter powder by chemical precipitation method, and prepare doped ZnO by doping ion solution soaking method * The crystal grains were sintered at 950°C for 2 hours, and the types and ratios of doped ions are listed in Table 6.

[0079] Table 6. Doped ZnO * Each dopant ion species and molar ratio in the grain (ZnO is 1mol)

[0080]

[0081] As in Example 1, it was made into a wafer-shaped zinc oxide varistor, and its properties are listed in Table 7. Among them, the potential gradients of the zinc oxide varistors prepared with sample numbers 1 to 4 all exceeded 1200V / mm, the nonlinear characteristic α exceeded 27.41, and the leakage current I L less than 16.5µA. In particular, the potential gradient of the prepared sample number 4 zinc oxide varistor is as high as 6023V / mm.

[0082] Table 7. ZnO doped with different ions * Performance of zinc oxide varistors made of crystal grains

[0083]

PUM

| Property | Measurement | Unit |

|---|---|---|

| current | aaaaa | aaaaa |

| current | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com