Paper gravure continuous positioning and flocking method and apparatus thereof

A paper and flocking technology, which is applied in the field of paper gravure continuous positioning flocking method and its device, can solve the problems of poor three-dimensional effect, irregularity, and easy fall-off of fluff, and achieve low production cost, simple operation, and firm flocking. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025]

[0026] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below.

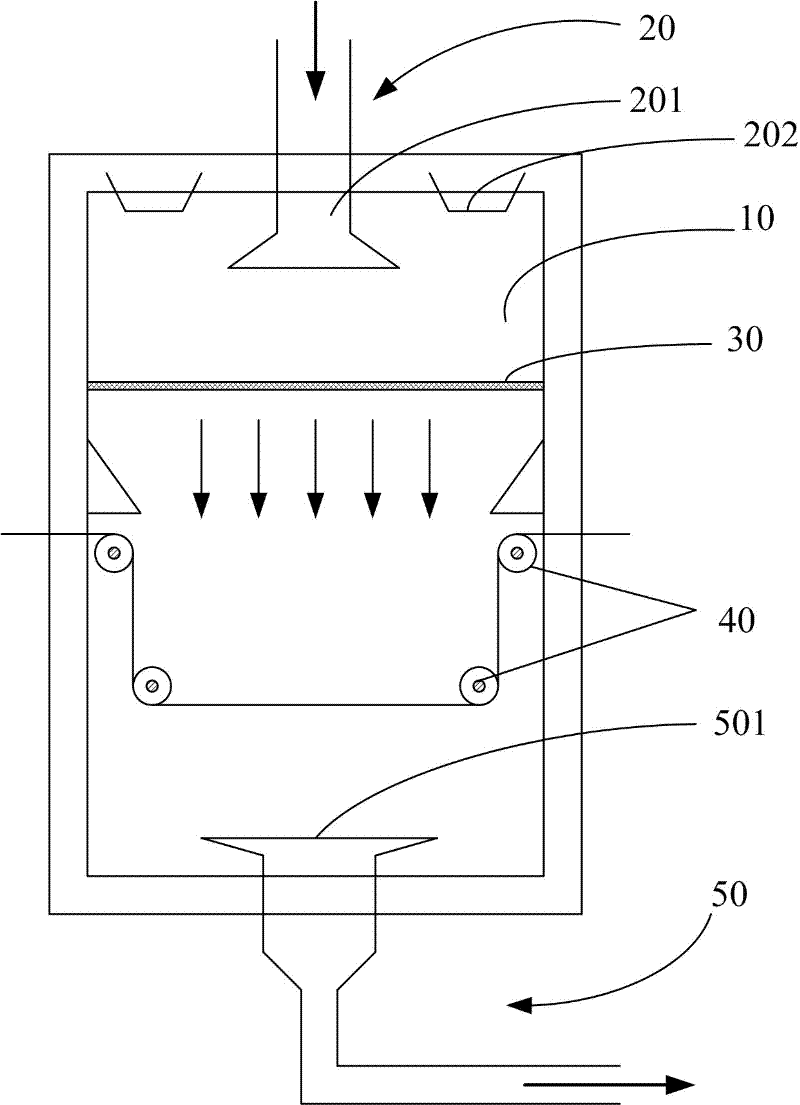

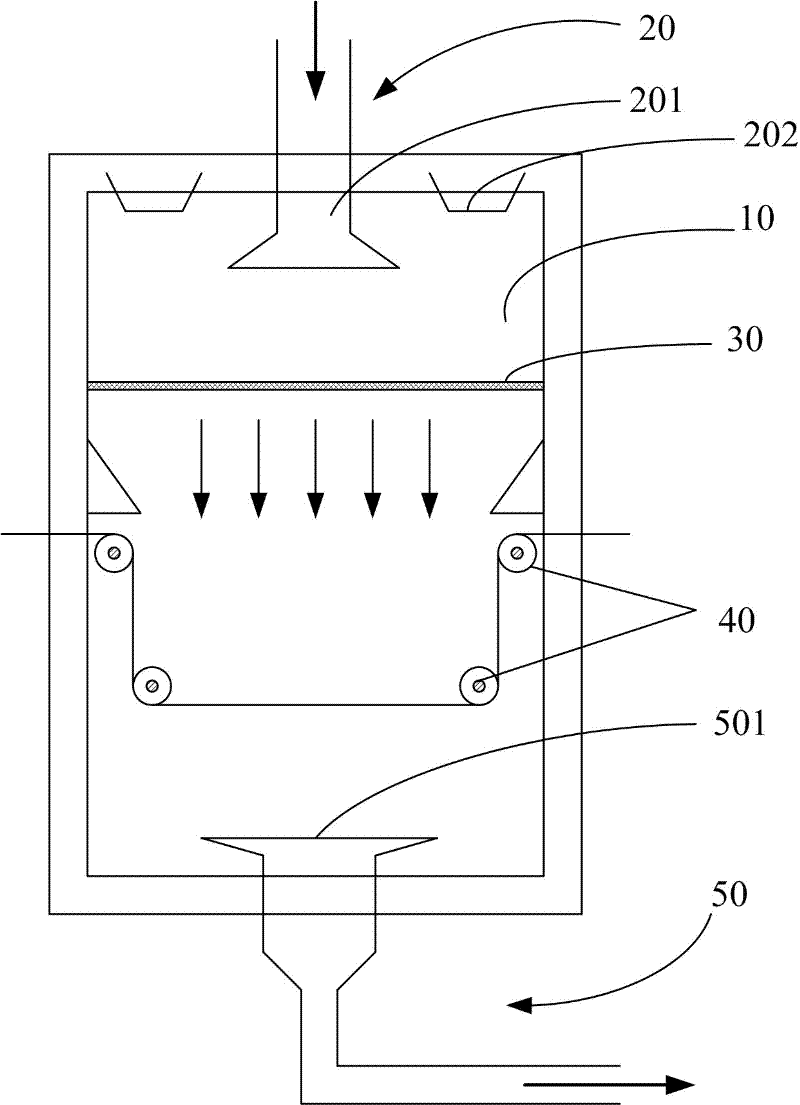

[0027] The invention discloses a paper gravure printing continuous positioning flocking method, in which the water-based varnish and adhesive glue are positioned and coated on the paper printed in the preliminary step by means of gravure printing, and the pattern to be flocked is formed, and the continuous flocking is carried out ,Specific steps are as follows:

[0028] Step 1: Printing, the paper is printed on the printing machine according to the design patterns required for packaging and decoration, and the ink is dried for further flocking.

[0029] Step 2: Track the first gravure roller and the second gravure roller, that is, the varnish coating roller and the glue coating roller, and synchronize the motors of the two, so that the gravure roller and the flocking part on the paper Carry out po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com