Tunnel digging equipment

A technology for tunnel excavation and equipment, which is used in tunnels, tunnel linings, mining equipment, etc., can solve the problems of not being able to directly see all the face conditions, not being able to observe the construction conditions ahead, and invisible construction, etc. The effect of supporting equipment and power consumption, low equipment cost, and less equipment failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The invention will be further explained in conjunction with the accompanying drawings and preferred embodiments. It should be noted that the preferred embodiments should not be used as limitations on the technical solutions of the invention.

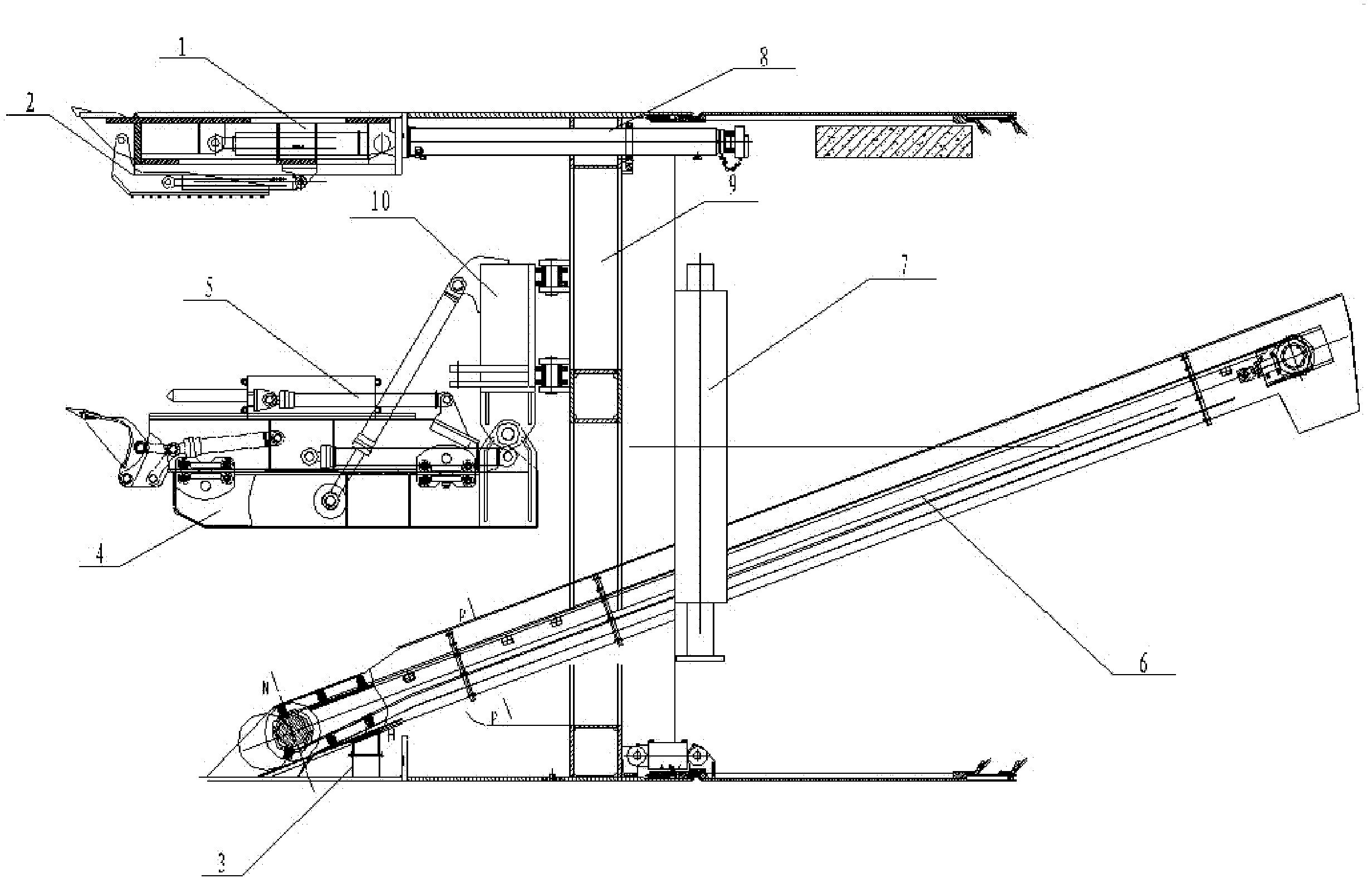

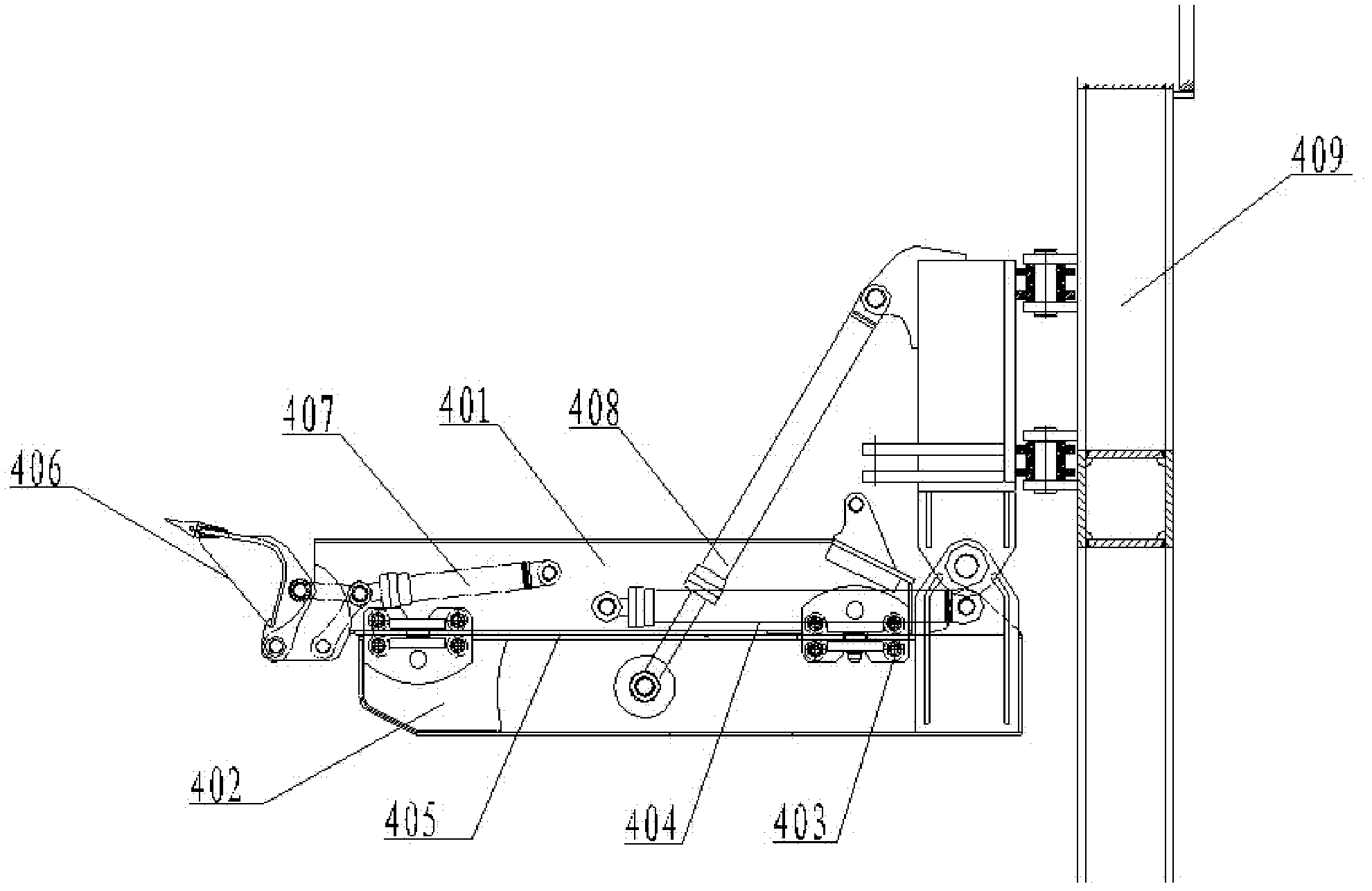

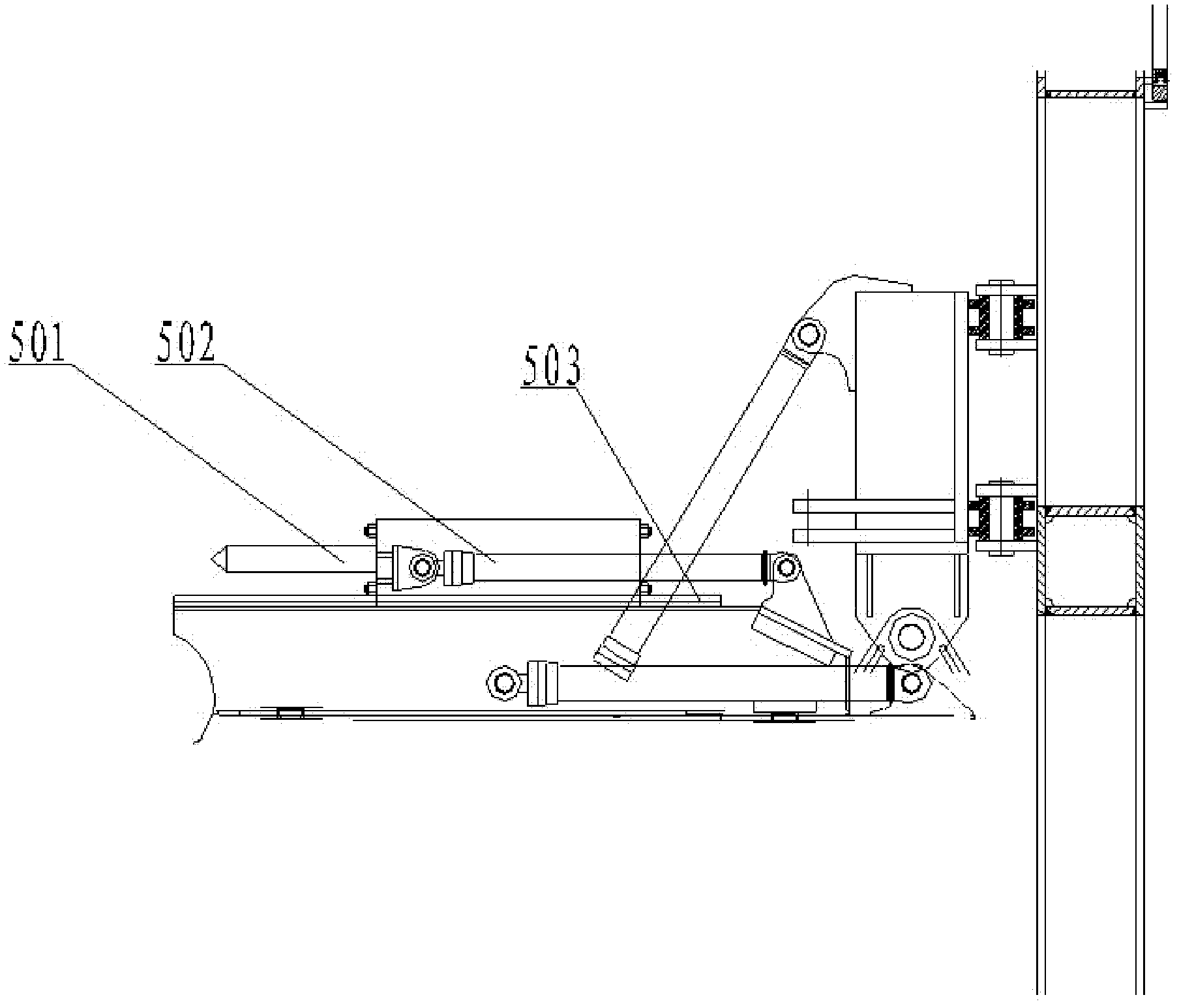

[0026] combine figure 1 , Tunnel excavation equipment, including a mechanism for maintaining the stability of the soil in the tunnel, an excavation and crushing mechanism, a jack 8 as a supporting mechanism, a screw conveyor 6 and a segment installation machine 7. A jack 8 is installed on the top of the equipment support ring beam 9, and the support frame 409 of the equipment support ring beam is connected to the excavation and crushing mechanism through a swing seat 10, and the bottom of the support frame 409 of the equipment support ring beam is inclined to be provided with a screw conveyor 6. Segment installer 7 is bolted together by guide rail and shield body. The screw conveyor 6 is used to transport the earthwork into the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com