Bender hydraulic system

A hydraulic system and bending machine technology, applied in the direction of mechanical equipment, fluid pressure actuators, servo motors, etc., can solve the problems of complex back pressure in the unloading circuit, low control stability valve group, and bulky products, etc., to achieve The effect of improving the stability of work progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

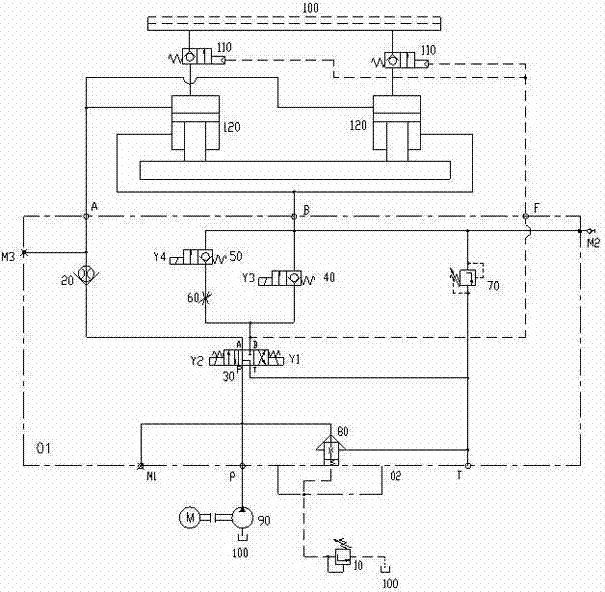

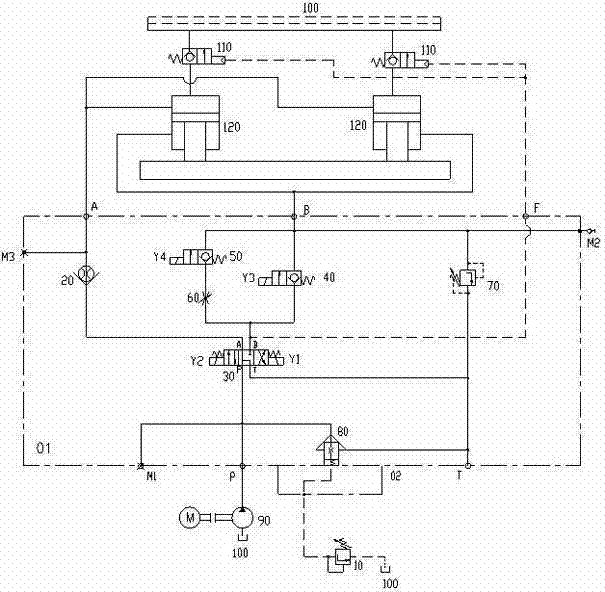

[0012] The technology will be further described below in conjunction with the accompanying drawings.

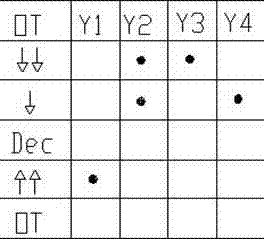

[0013] see figure 1 The hydraulic system of the bending machine shown in , includes an oil pump 90 , an oil tank 100 , and a three-position four-way reversing valve 30 . The filling valve 110 is connected between the oil tank 100 and the upper cavity of the oil cylinder 120 . The oil outlet of the oil pump 90 is connected to the oil tank through the two-way cartridge valve 80. The remote pressure regulating valve 10 is connected to the control port of the two-way cartridge valve 80 .

[0014] The P port of the three-position four-way reversing valve 30 is connected to the oil outlet of the oil pump 90, the B port is connected to the lower chamber of the oil cylinder through the first electromagnetic reversing valve 40, and the A port is connected to the upper chamber of the oil cylinder through the throttling check valve 20. Port B of the three-position four-way reversing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com