SF6 leakage plugging method of GIS (Gas Insulated Switchgear)

A technology of gas leakage and SF6, which is applied in the direction of mechanical equipment, pipes/pipe joints/fittings, pipe components, etc., can solve the problems of long working hours, reduced electricity sales, and no solution for gas leakage, etc., to achieve convenient production, The effect of reducing operation risk and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] 1. For the leak plugging steps at the welded part of the pipeline: use the sample punch to hammer and rive the leak point. choose. After the impact of the sample punch, a clean surface is produced, and the sealant is used to seal the leak point on the clean surface.

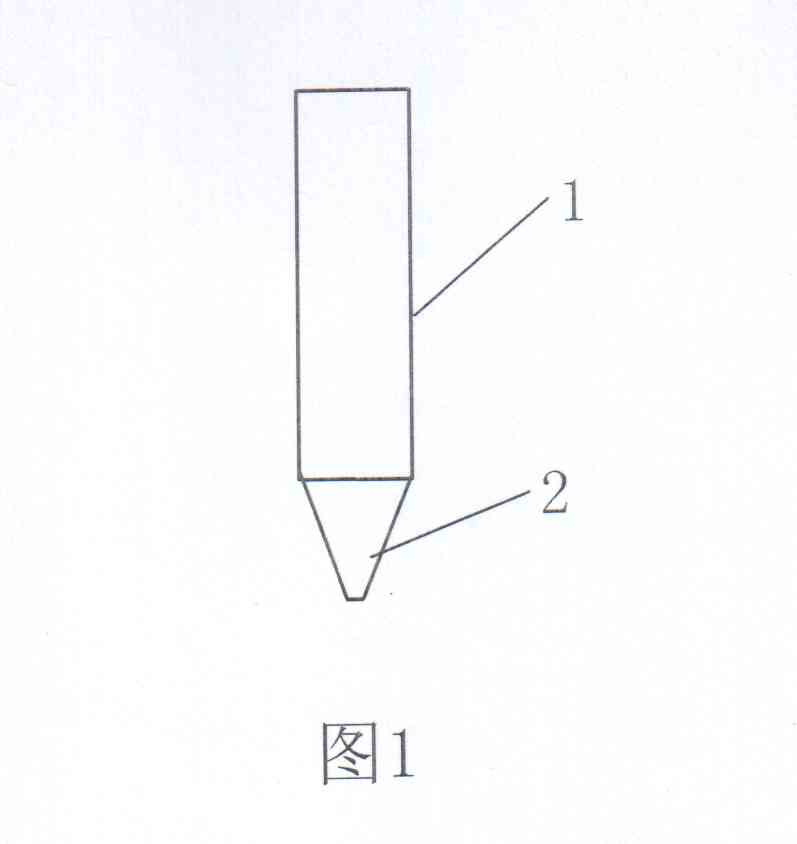

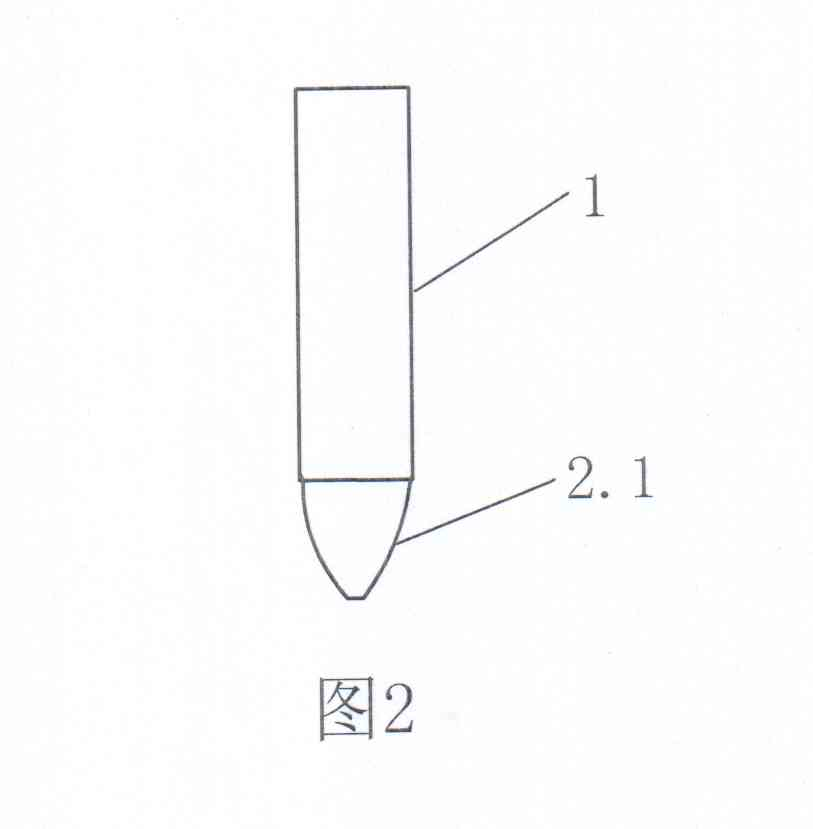

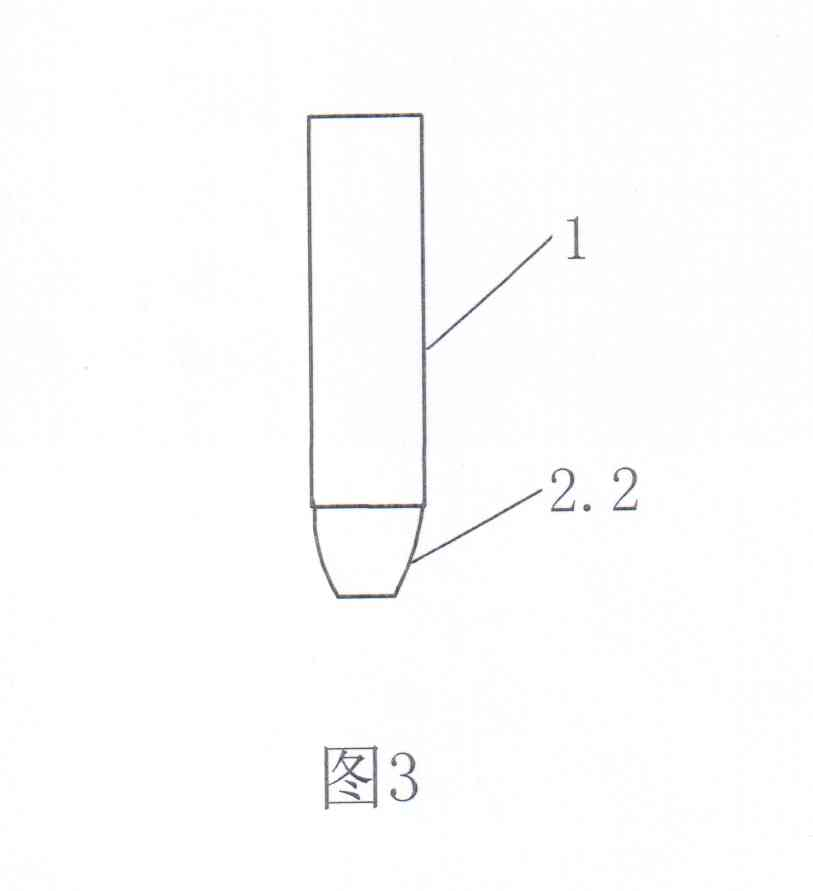

[0020] Sample structure such as figure 1 , 2 , 3 and 4 show:

[0021] The sample punch is a metal rod-shaped object, and a punch tip 2 is provided at the end of the punch rod 1 .

[0022] Blunt tip-like punch: the punch tip is blunt tip 2.1;

[0023] Flat tip sample punch: the punch tip is flat tip 2.2;

[0024] Concave punch: the punch tip is concave 2.3.

[0025] The rod-shaped part is the hand-held part, and the punching point is used to impact the leakage point of the air leakage part to produce a clean surface, which is conducive to the adhesion and curing of the sealant, and realizes the sealant sealing of the leakage point.

[0026] 2. Leakage and plugging steps of cylindrical pipe wall: man...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com