Time-sharing automatic sampling device for powder production and control method

An automatic sampling device and the technology of sampling device, which are used in the control of automatic sampling device and the field of automatic sampling device for time-sharing in powder production, can solve the problem that the average quality of materials cannot be accurately reflected, and the quality data of sample inspection and analysis is not representative, etc. problems, to achieve the effect of increasing collection frequency, reducing labor intensity, and prolonging collection time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

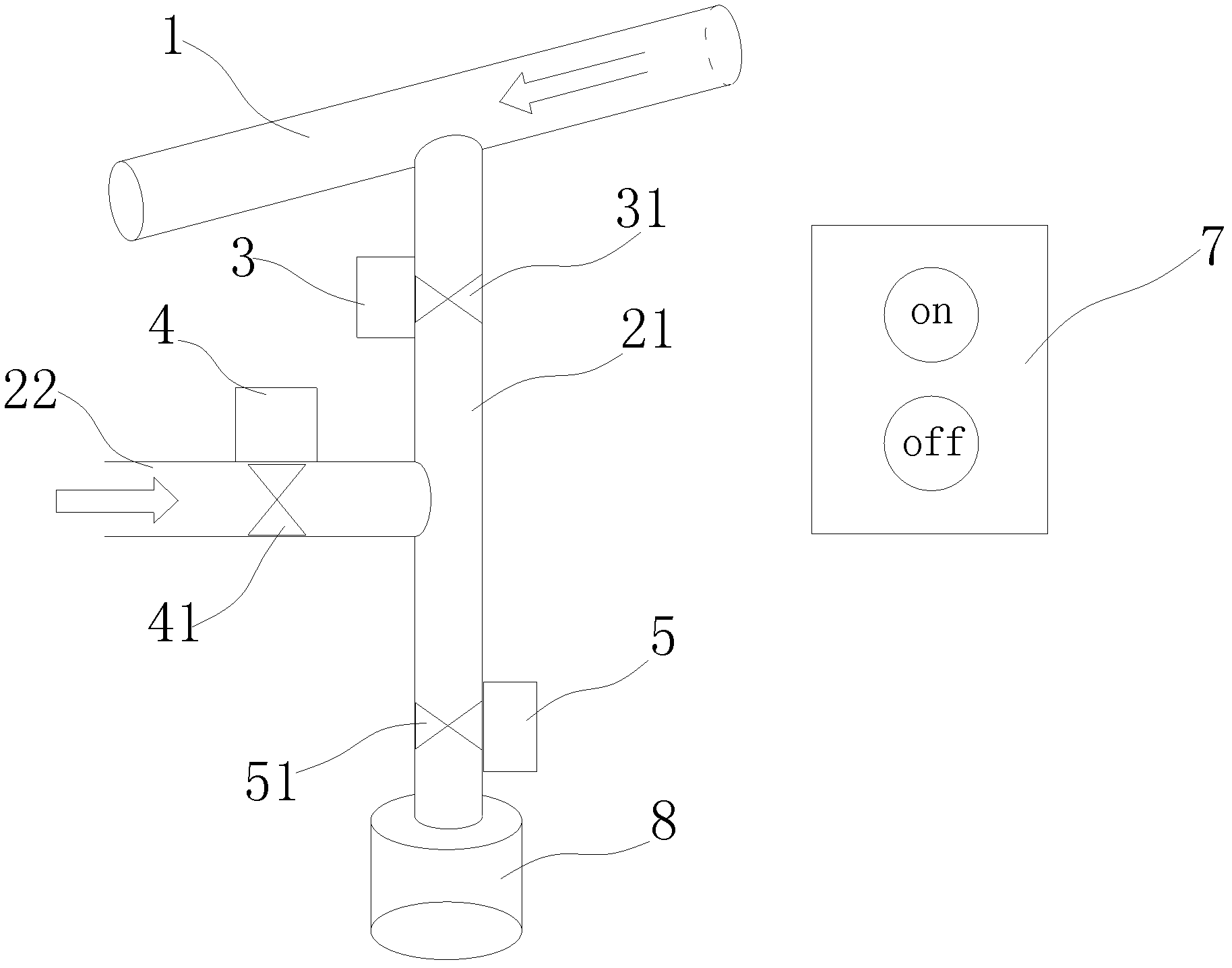

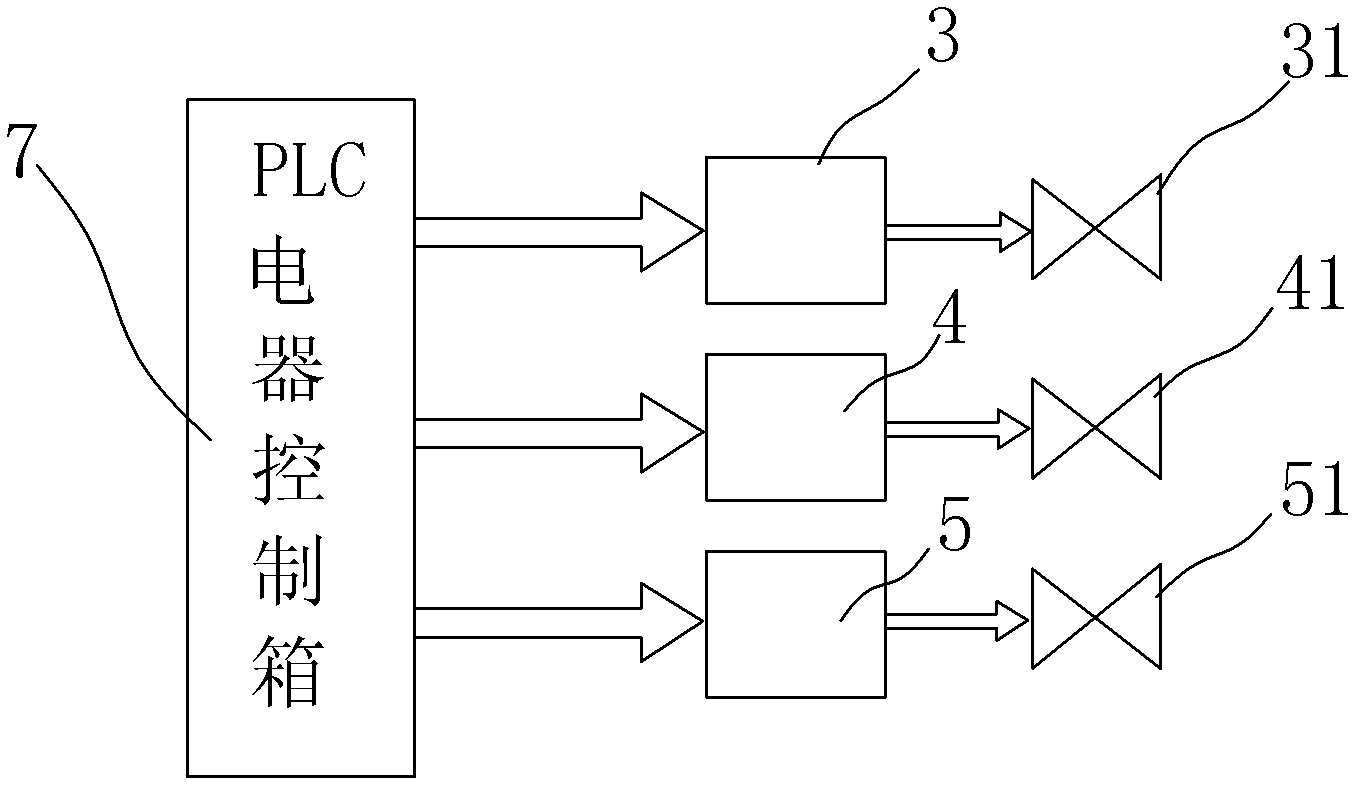

[0020] Such as figure 1 As shown, a time-sharing automatic sampling device for powder production includes an air chute 1 and a sampling device connected below the air chute. During work, the powdery material flows to the sampling device through the air chute. The sampling device includes a vertical The pipeline 21 and the horizontal pipeline 22 connected with it, input compressed air in the horizontal pipeline, and the bottom of the vertical pipeline 21 is a sampling bucket 8, and the sampling bucket is used to accommodate the collected powder samples. The upper and lower ends of the vertical pipe 21 are respectively provided with a first solenoid valve 31 connected to the first time relay 3 and a third solenoid valve 51 connected with the third time relay 5, and the horizontal pipe 22 is provided with the second The second solenoid valve 41 connected to the time relay 4, and the three time relays 3, 4, 5 are all connected to the PLC electrical control box 7.

[0021] Before ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com