Method for determining rock conjugate damage strength through adopting supersonic waves

An ultrasonic and rock technology, used in the analysis of solids, strength characteristics, instruments, etc. using sonic/ultrasonic/infrasonic waves, can solve the problems of rock interpretation errors, expensive, determination and judgment errors, etc., and achieves simple equipment and low test conditions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

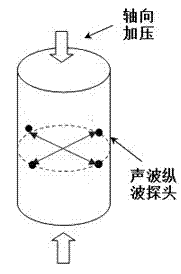

[0037] A method for determining the conjugate damage strength of rock by ultrasonic waves, comprising the following steps:

[0038] Step 1: Fix a pair of longitudinal wave probes at both ends of two mutually perpendicular diameters on a certain cross-section in the middle of the rock sample, that is, the first longitudinal wave transmitting probe, the first longitudinal wave receiving probe, the second longitudinal wave transmitting probe and the second longitudinal wave receiving probe. probe;

[0039]Step 2: Carry out pressure loading on the rock sample, and during the loading process, continuously test the rock acoustic wave velocity between the two mutually perpendicular diameters of the rock sample at a time interval T through the fixed longitudinal wave probe in step 1, until the rock sample is destroyed; Here, T takes 1 to 3s, and the specific operation steps of step 2 are as follows:

[0040] Step 2.1, start the test button of the acoustic wave tester at a certain tim...

Embodiment 2

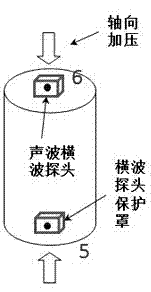

[0046] A method for determining the conjugate damage strength of rock by ultrasonic waves, comprising the following steps:

[0047] Step 1, fixing a pair of longitudinal wave probes at both ends of a diameter on a certain longitudinal section in the middle of the rock sample, i.e. the first shear wave transmitting probe and the first shear wave receiving probe;

[0048] Step 2. Pressure loading is carried out on the rock sample, and during the loading process, the diameter of the rock sample and the rock acoustic wave velocity are continuously measured at time intervals T through the shear wave probe fixed in step 1 until the rock sample is destroyed; here, T takes 1~ 3s, the specific operation steps are as follows:

[0049] Step 2.1, start the test button of the acoustic wave tester at a certain time t1, the first longitudinal wave transmitting probe emits ultrasonic waves, and after time Δt1 reaches the first longitudinal wave receiving probe, divide the diameter d of the ro...

Embodiment 3

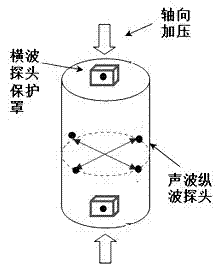

[0053] A method for determining the conjugate damage strength of rock by ultrasonic waves, comprising the following steps:

[0054] Step 1: Fix a pair of longitudinal wave probes at both ends of two mutually perpendicular diameters on a certain cross-section in the middle of the rock sample, that is, the first longitudinal wave transmitting probe, the first longitudinal wave receiving probe, the second longitudinal wave transmitting probe and the second longitudinal wave receiving probe. Probes; a pair of longitudinal wave probes are fixed at both ends of a diameter on a certain longitudinal section in the middle of the rock sample, that is, the first shear wave transmitting probe and the first shear wave receiving probe;

[0055] Step 2: Pressure loading is carried out on the rock sample, and during the loading process, the longitudinal wave probe and the shear wave probe fixed in step 1 are used to continuously test the distance between two mutually perpendicular diameters an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com