Low-temperature performance evaluation method for lithium ion battery

A lithium-ion battery, low-temperature performance technology, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems of poor electrical conductivity, limited dynamic characteristics, etc., and achieve the effect of accurate measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

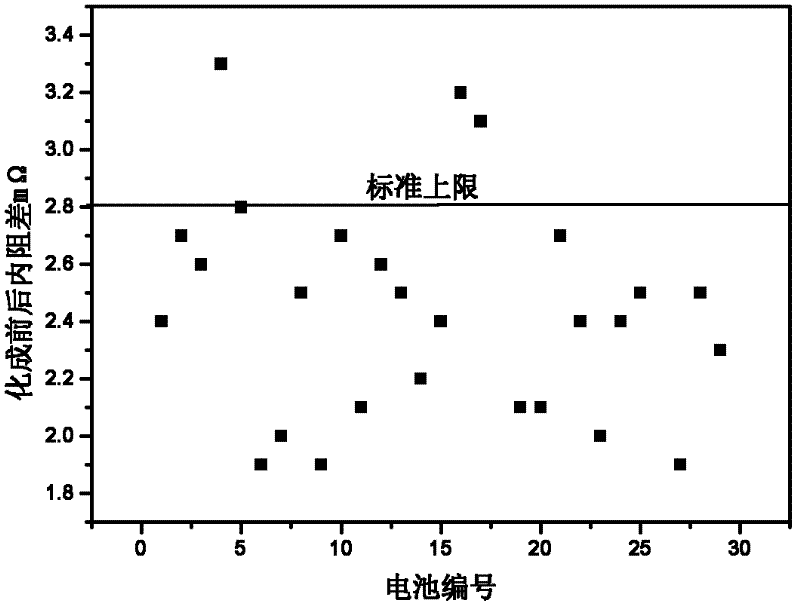

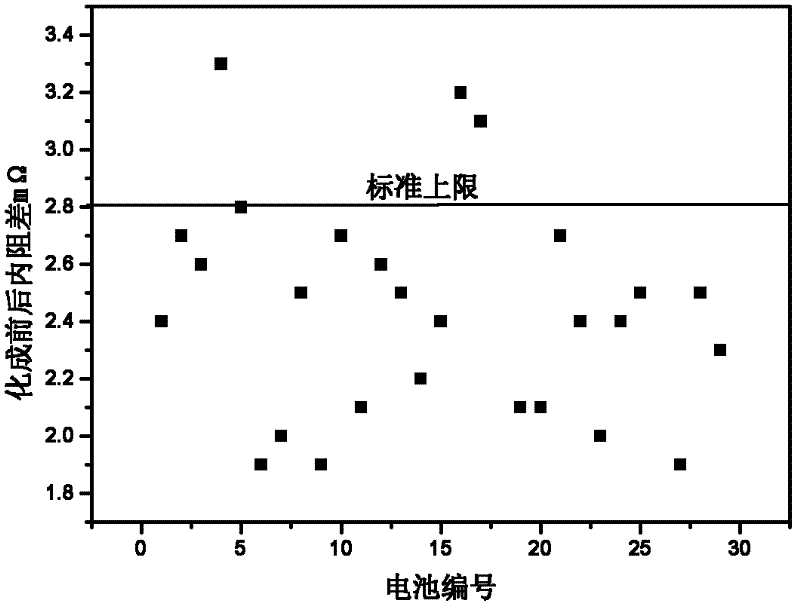

[0014] Example 1: The new lithium-ion battery evaluation method of the present invention is applied to a certain type of 10Ah single battery, respectively measuring the internal resistance difference of 30 single batteries before and after formation, and the measurement results are shown in the attached figure 1 .

[0015] Determine the standard value for the selection of lithium-ion batteries or battery packs, and take the densely distributed area as the upper limit of the standard value (for an example, see the attached figure 1 ,30 groups of 3.2V / 10Ah batteries have internal resistance difference before and after formation, the maximum internal resistance difference is 3.3mΩ, most of them are between 1.9-2.8mΩ, so 2.8mΩ is selected as the upper limit of the standard value) Specifically: Measure the internal resistance of 30 groups of batteries before and after formation, take the difference, and select three batteries with internal resistance differences of 3.3, 2.6, and ...

Embodiment 2

[0016] Example 2: The low temperature performance evaluation method of lithium ion battery comprises the following steps:

[0017] (1) Determination of internal resistance sorting standard values before and after formation of lithium-ion batteries: According to each type of lithium-ion batteries stored in an environment below the low temperature dew point -40°C for 24 hours, then draw the measurement distribution results of internal resistance, and take the distribution The dense area is the upper limit of the standard value;

[0018] (2) Test the internal resistance of the lithium-ion battery to be tested before and after formation, and then compare the measured internal resistance difference of the lithium-ion battery to be tested before and after formation with the determined internal resistance sorting standard value of the lithium-ion battery before and after formation Compared;

[0019] (3) If the internal resistance of the lithium-ion battery is less than the stand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com