Large-mode-area single-mode fiber connector and manufacture method

A single-mode optical fiber and connector technology, which is applied in the field of single-mode optical fiber connectors and manufacturing, can solve problems such as the inability to achieve physical contact with the end face of the optical fiber, the inability to eliminate Fresnel reflection, and the difficulty in controlling return loss, etc., to achieve beam expansion Good effect, simple structure and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

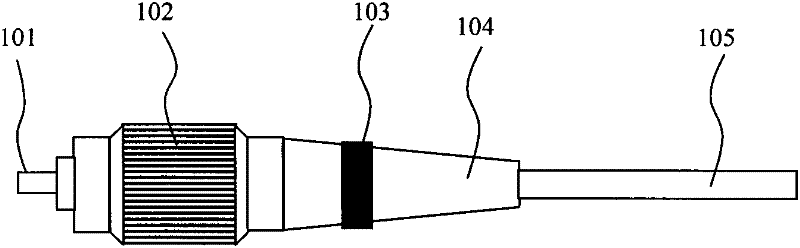

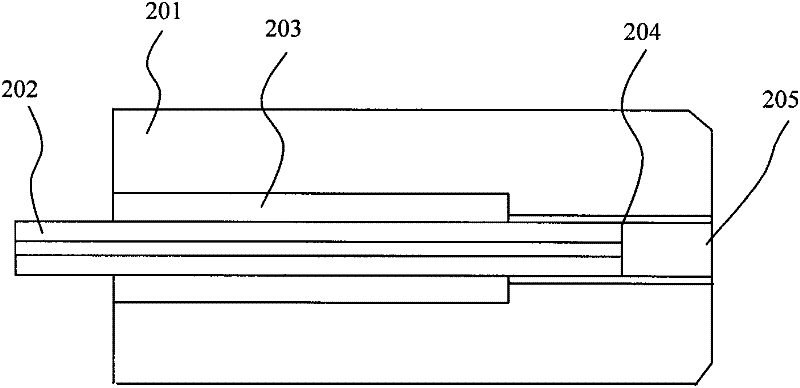

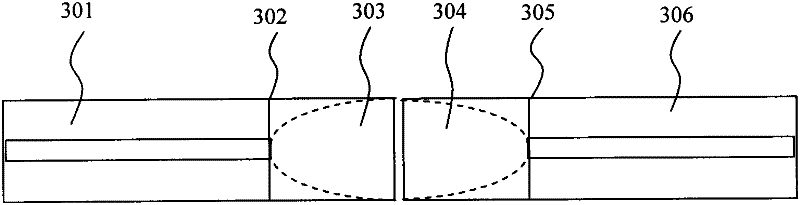

[0014] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings. as attached figure 2 As shown, the single-mode optical fiber 202 is a standard single-mode communication optical fiber (G652), with a core diameter of 8.2 μm, a cladding diameter of 125 μm, and a numerical aperture of 0.14. First remove its protective coating, and then use a fiber optic cutter to cut its end face perpendicular to its axis. The graded-index lens 205 is made by using Nufern MM-S105 / 125-15A step-index multimode fiber through high-temperature treatment. MM-S105 / 125-15A has a core diameter of 105 μm, a cladding diameter of 125 μm, and a numerical aperture of 0.14. First remove its protective coating, place it in a high-temperature tubular heating furnace, and heat it at 1100°C for 30 minutes. In the high temperature state, the germanium element in the fiber core of MM-S105 / 125-15A will diffuse outward from the cent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com