Micro mixing and micro reaction device

A micro-reaction device and micro-mixing technology, applied in mixers, chemical instruments and methods, and laboratory containers, can solve problems such as high cost, difficult processing, and singleness, and achieve convenient connection, improved mixing efficiency, and The effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

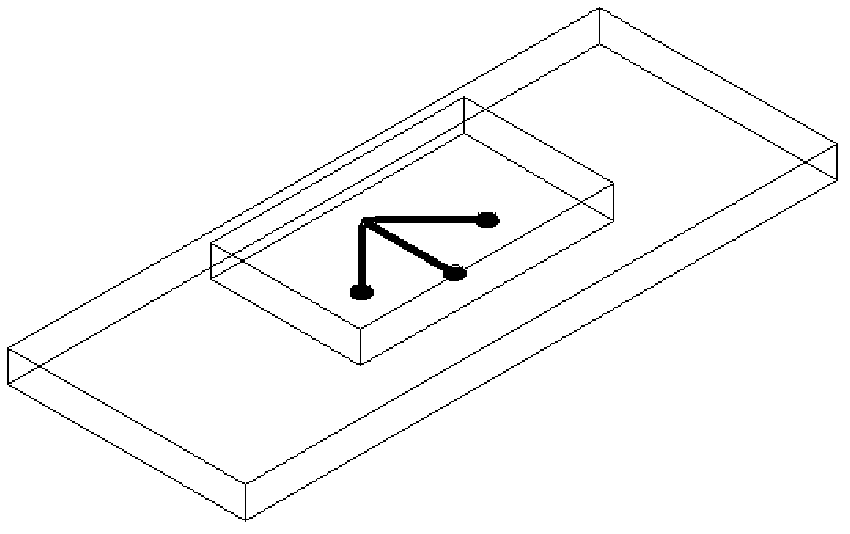

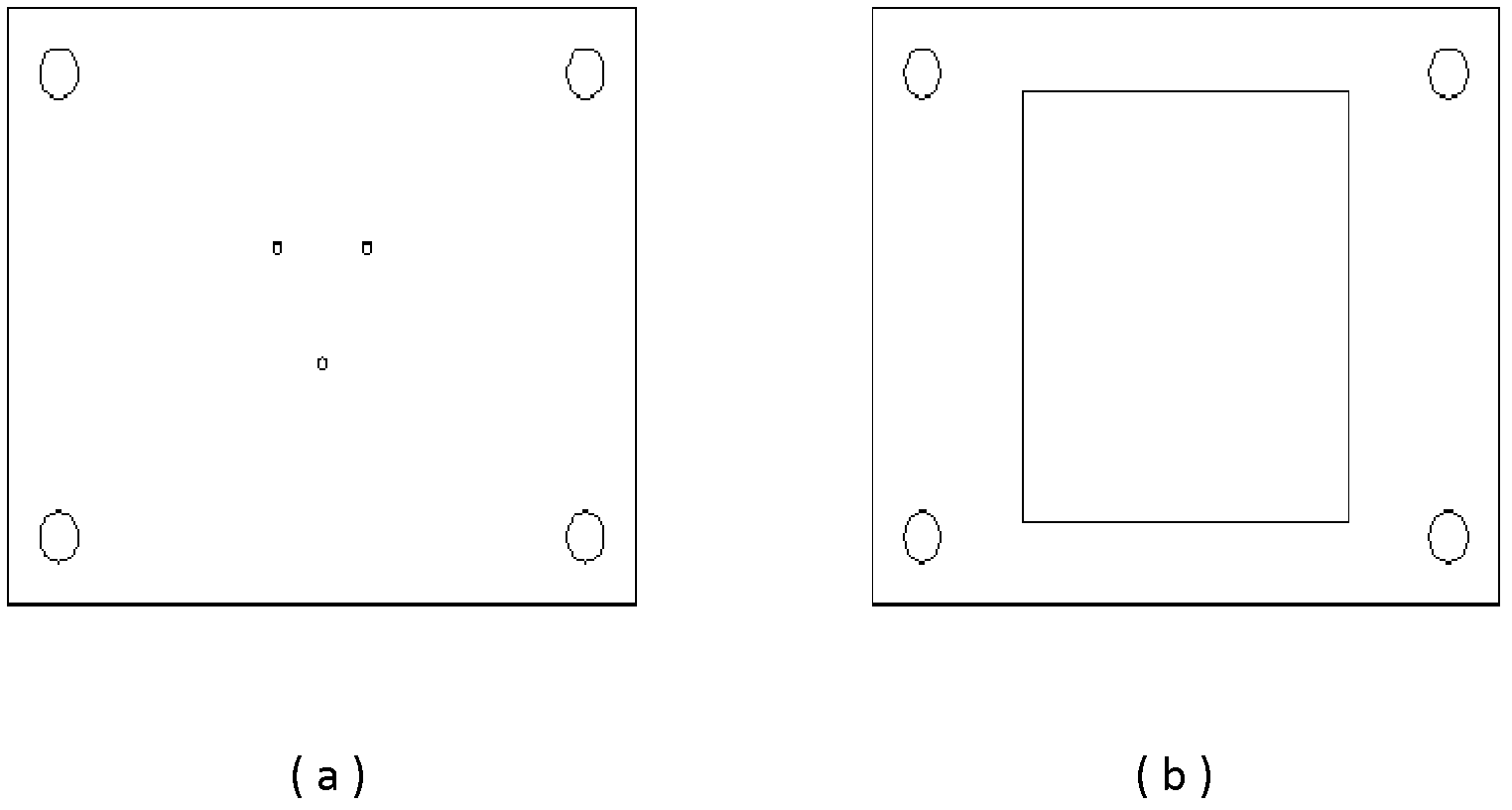

[0039] In this embodiment, the micro-mixing and micro-reaction device consists of two parts: a microfluidic chip and a chip clip.

[0040] Such as Figure 1-2 As shown, the microfluidic chip is a polydimethylsiloxane (PDMS) microfluidic chip, which is formed by bonding a thin layer of polydimethylsiloxane (PDMS) with a microchannel structure and a glass sheet .

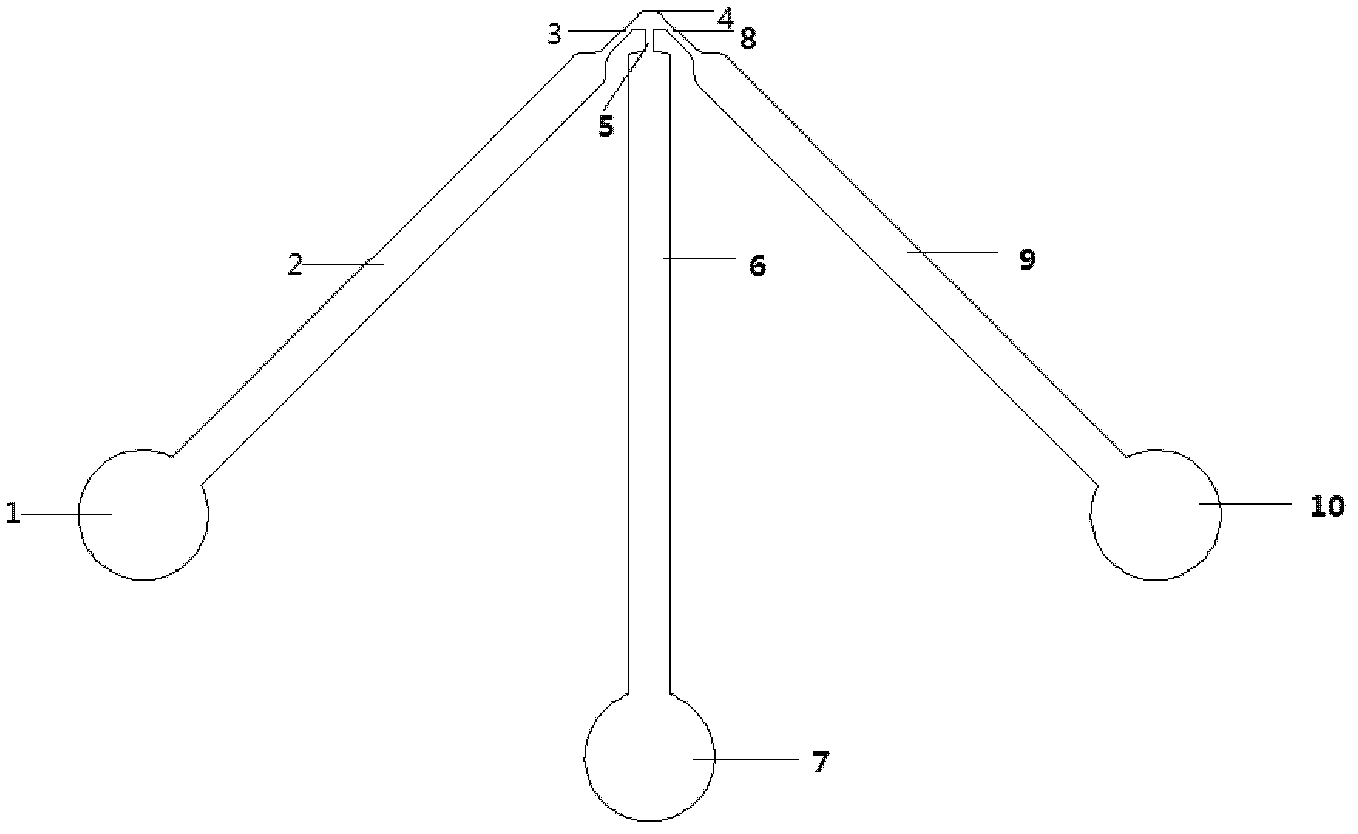

[0041] The microchannel structure in the PDMS thin layer is three connected channels, such as figure 2 shown. It includes two inlet passages and one outlet passage, and the two inlet passages and one outlet passage communicate through the mixing chamber 4 .

[0042]In the present embodiment, the angle of the central axes of the two inlet passages is 90 degrees, and the solutions are respectively from the inlet passage reservoirs 1 and 10 (the inlet passage reservoirs in this embodiment a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com