High-precision spring machine

A spring machine, high-precision technology, applied in the field of spring machines, can solve the problems affecting the spring machining accuracy, increase the difficulty of debugging, increase the difficulty of punching, etc., and achieve the effect of convenient debugging, reducing the difficulty of process realization and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

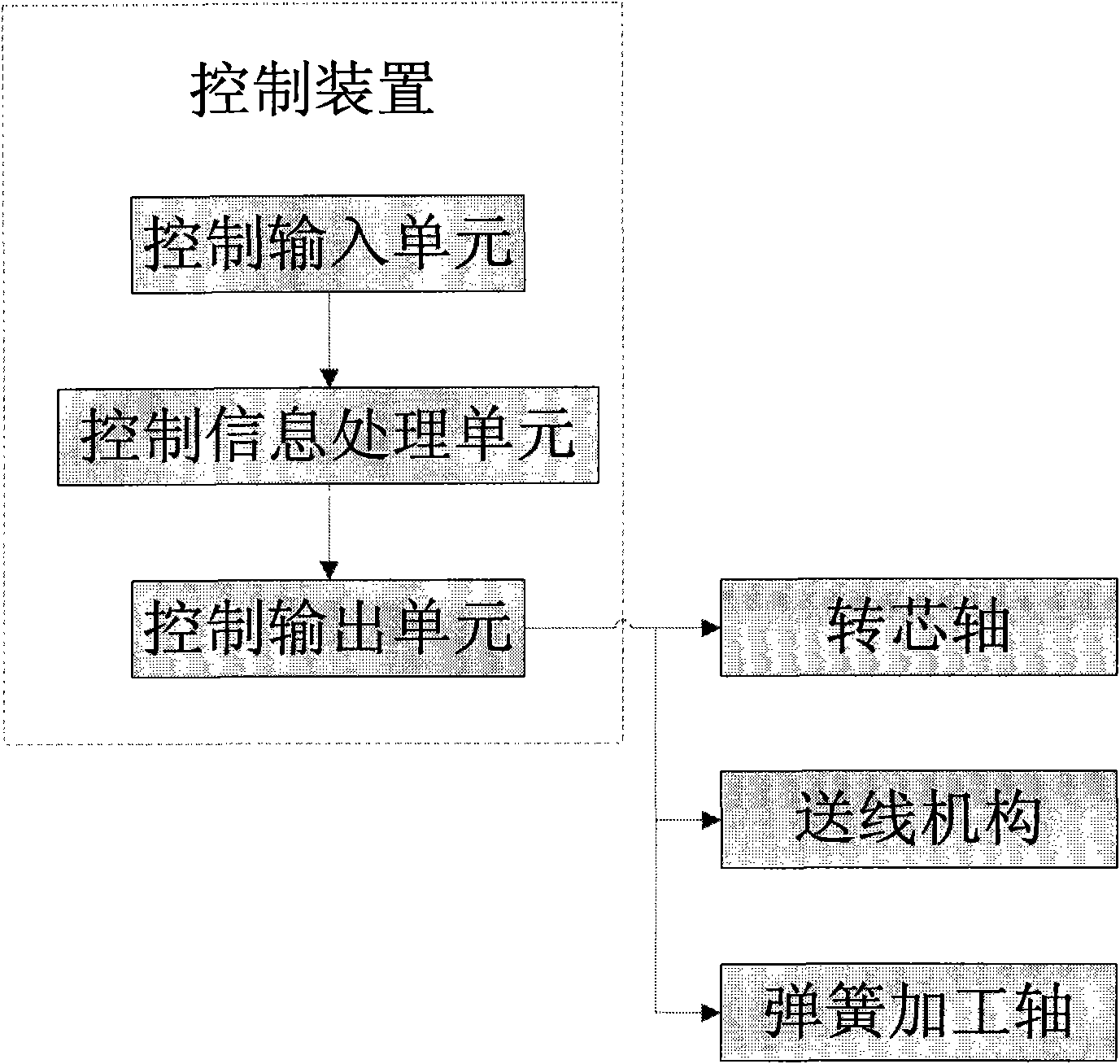

[0064] Embodiment 1: Take the three-axis spring machine as an example to specifically illustrate the specific implementation of the scheme:

[0065] Such as Figure 4 , where each spring processing axis is converted into a different specific spring processing axis according to the different processing cutter heads. If the processing end of the axis is a top thread cutter, the spring processing axis will be converted into a top thread axis. If the spring processing axis is equipped with a tangent knife, the spring processing axis will be converted into a tangent axis;

[0066]The spring processing shaft of the three-axis spring machine is three shafts, specifically the crimping shaft, which is used to bend the spring wire rod inward during the spring processing; the top wire shaft is used to cooperate with the top wire shaft during the spring processing to make the spring The shaft that forms the desired curved shape; the tangent shaft, the shaft used to cut the formed spring ...

Embodiment 2

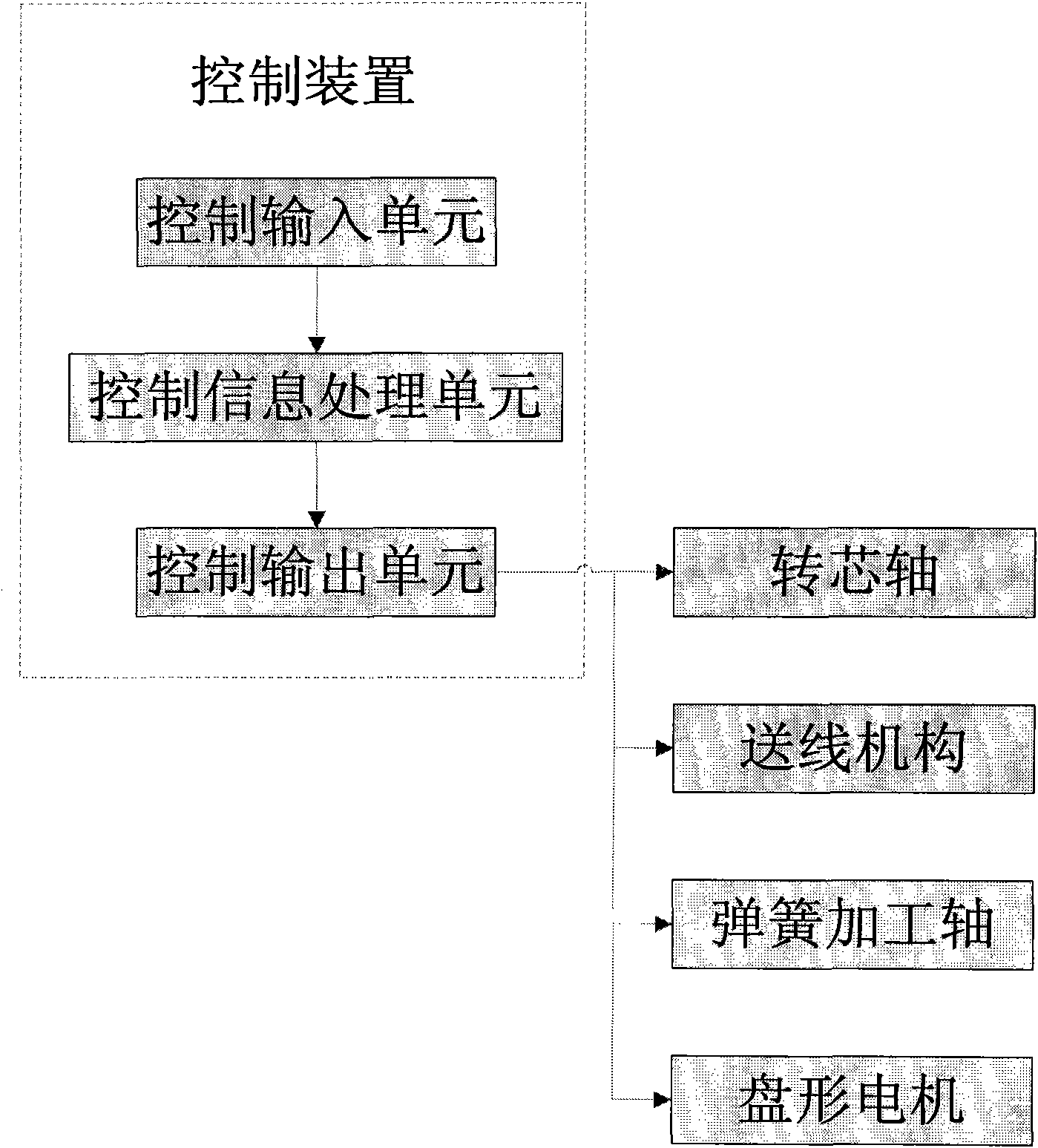

[0087] Taking the three-axis spring machine as an example to specifically illustrate the implementation of the improvement plan:

[0088] Such as Figure 5 , where each spring processing axis is converted into a different specific spring processing axis according to the different processing cutter heads. If the processing end of the axis is a top thread cutter, the spring processing axis is converted into a top thread axis. If the tool head of the spring processing axis is a tangent knife, the spring processing axis is converted into a tangent axis;

[0089] The spring processing shaft of the three-axis spring machine is three shafts, specifically the crimping shaft, which is used to bend the spring wire rod inward during the spring processing; the top wire shaft is used to cooperate with the top wire shaft during the spring processing to make the spring The shaft that forms the desired curved shape; the tangent shaft, the shaft used to cut the formed spring from the spring w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com