Device for scraping liquid tin-soldered oxide skin by semi-automatic tin immersion machine

The technology of a scraping device and a tin immersion machine is applied in the field of the device for removing the oxide scale of liquid solder and the tin immersion device for the pins of electrical components, which can solve the problem of poor connection between electrical components and wires or circuit boards, which affects the electrical components. The quality of tin on the pins and the large amount of solder oxide residues can ensure the quality of immersion tin, save solder materials, and have a compact structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with drawings and embodiments.

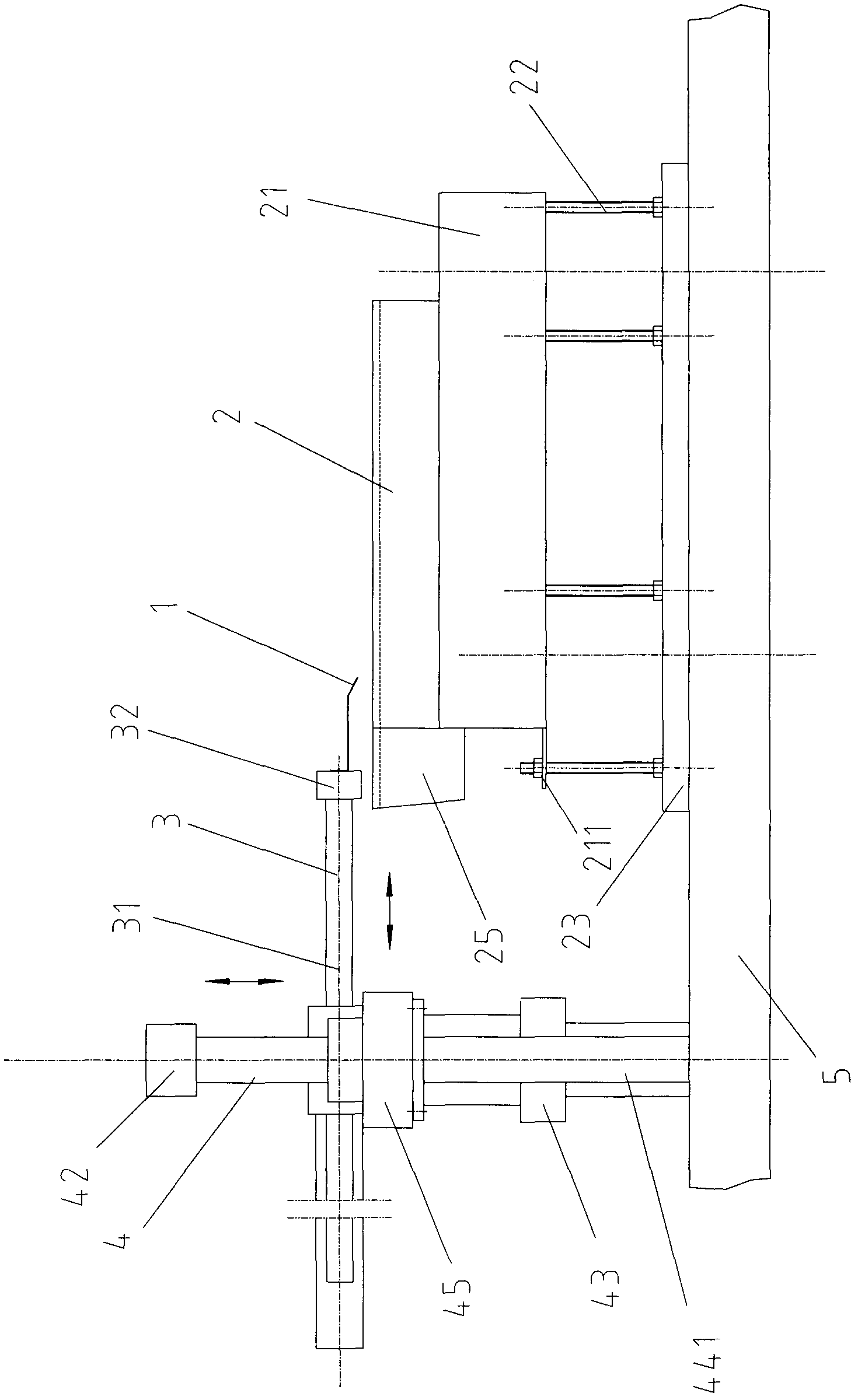

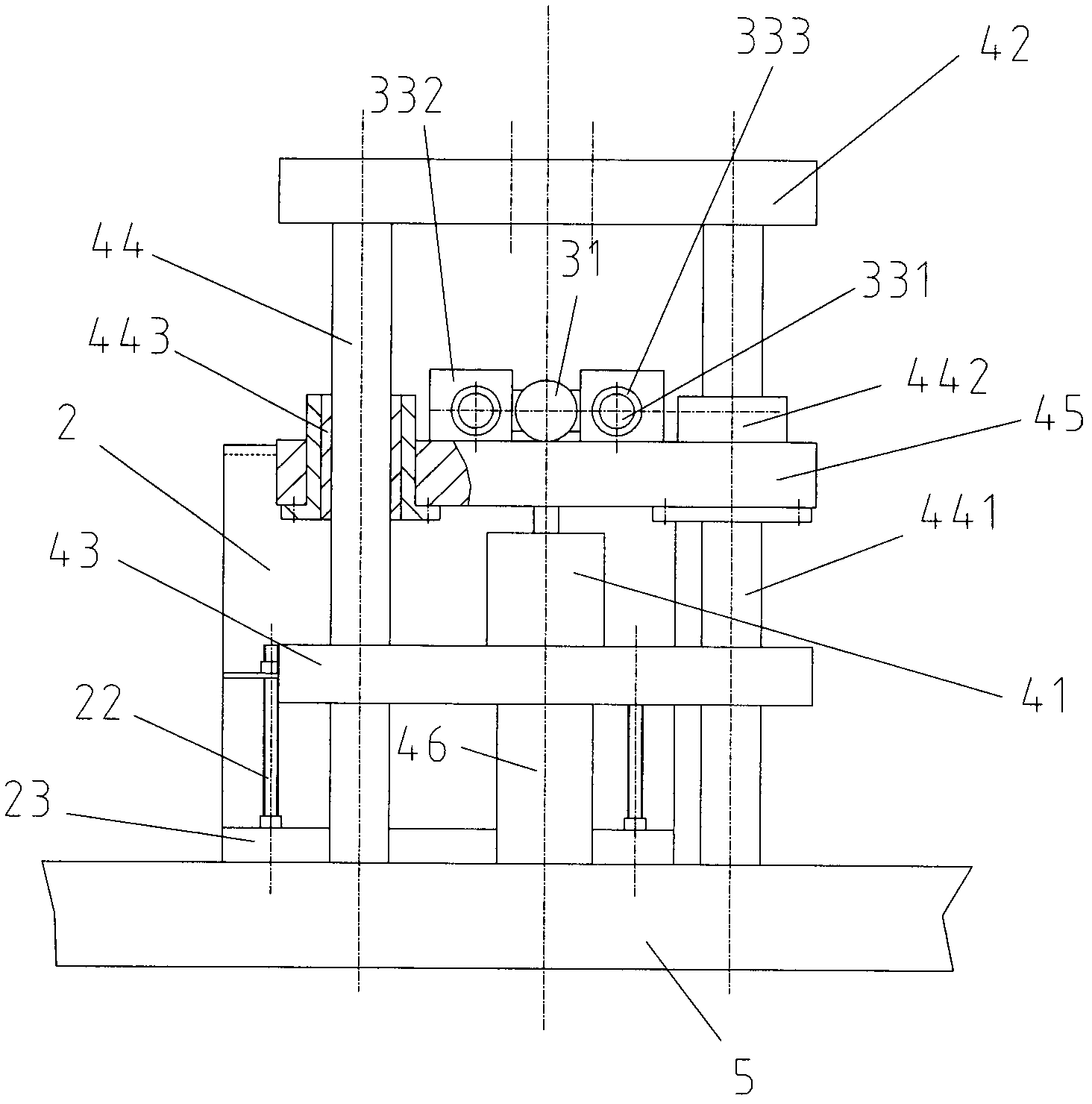

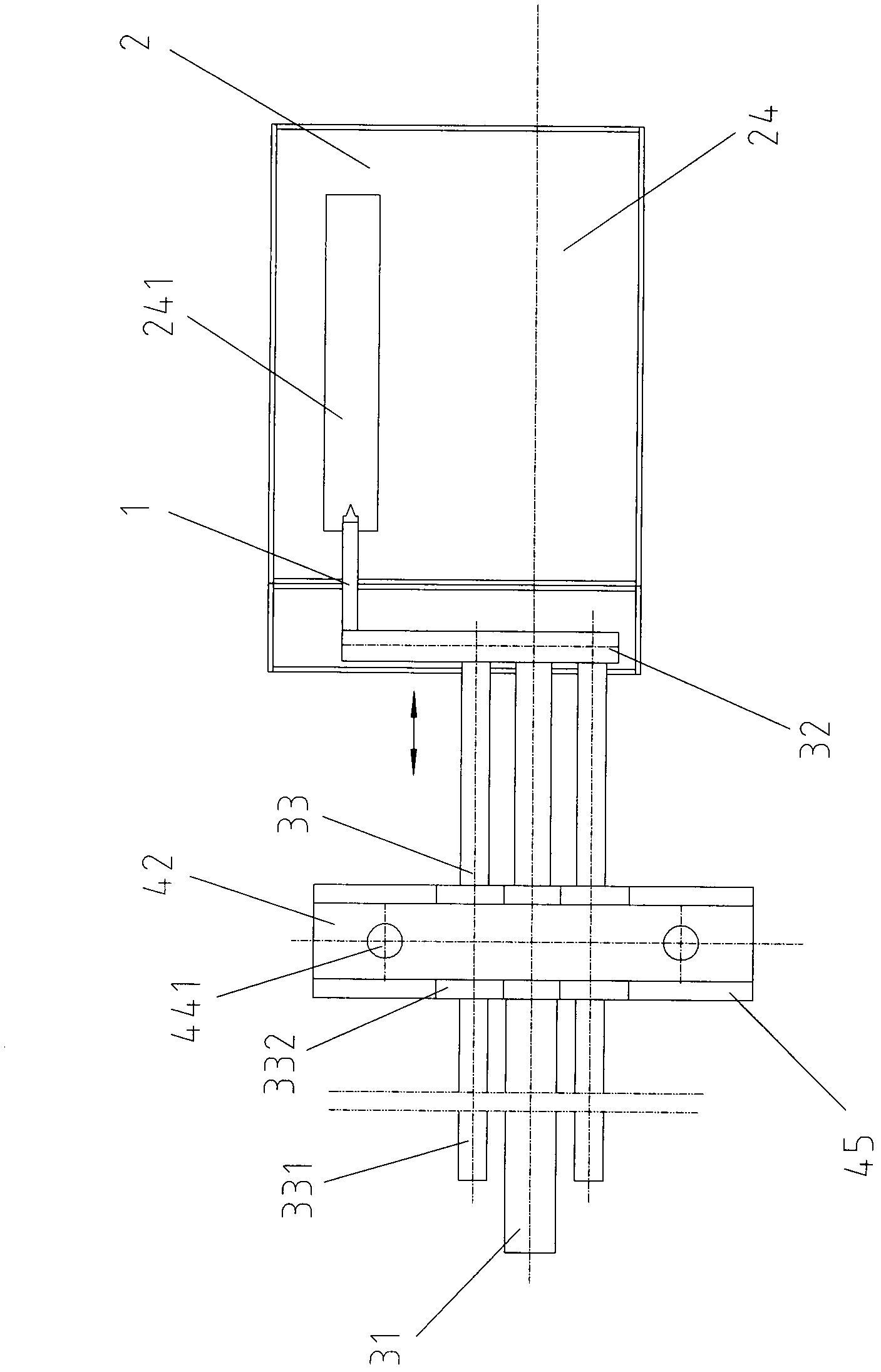

[0017] The electric element of the pin dipping tin of this embodiment is the speed measuring sensor stator assembly that is used for fully automatic washing machine, as Figure 1 ~ Figure 3 As shown, the liquid solder oxide scale scraping device of this embodiment includes a scraper 1, a molten tin pool 2, a scraper horizontal movement mechanism 3 and a scraper lifting mechanism 4, and the scraper horizontal movement mechanism 3 includes a horizontal drive cylinder 31, a scraper moving beam 32 and The scraper horizontally moves the guiding mechanism 33, the front end of the horizontal driving cylinder 31 is fixed on the middle part of the scraper lifting beam 45, the front end of the piston rod of the horizontal driving cylinder 31 is fixedly connected with the scraper moving beam 32, and the horizontal moving guiding mechanism 33 of the scraper is arranged on both sides...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com