Chip removing and cooling device for scraping roller machine and scraping roller machine

A technology of cooling device and chip conveyor, which is used in metal processing machinery parts, other manufacturing equipment/tools, maintenance and safety accessories, etc. Among the components, insufficient filtration, equipment failure and other problems, to achieve excellent filtration and cooling effects, improve filtration effect, and improve filtration accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation of the present invention will now be described with reference to the accompanying drawings, but it is only a preferred embodiment and is not used to limit the essential scope of the present invention.

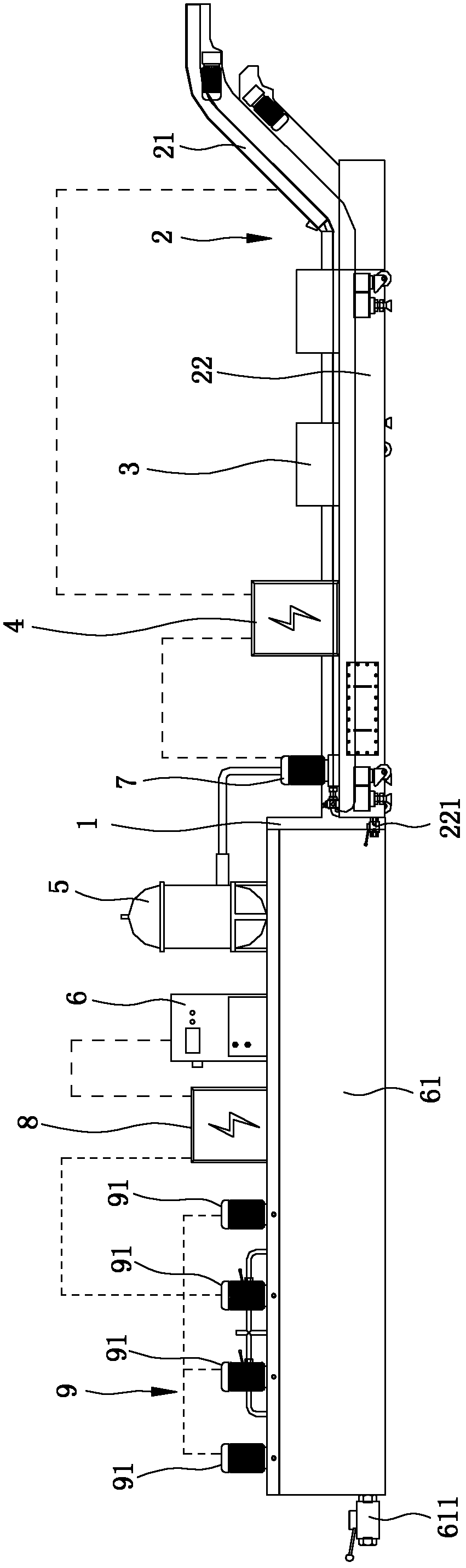

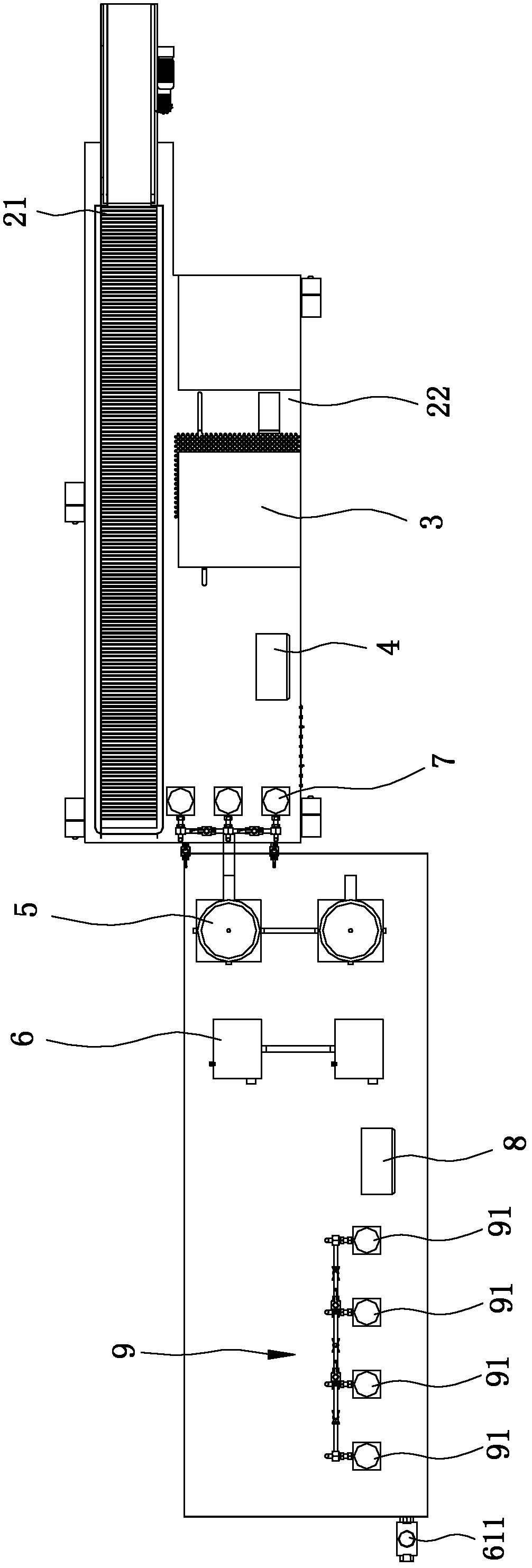

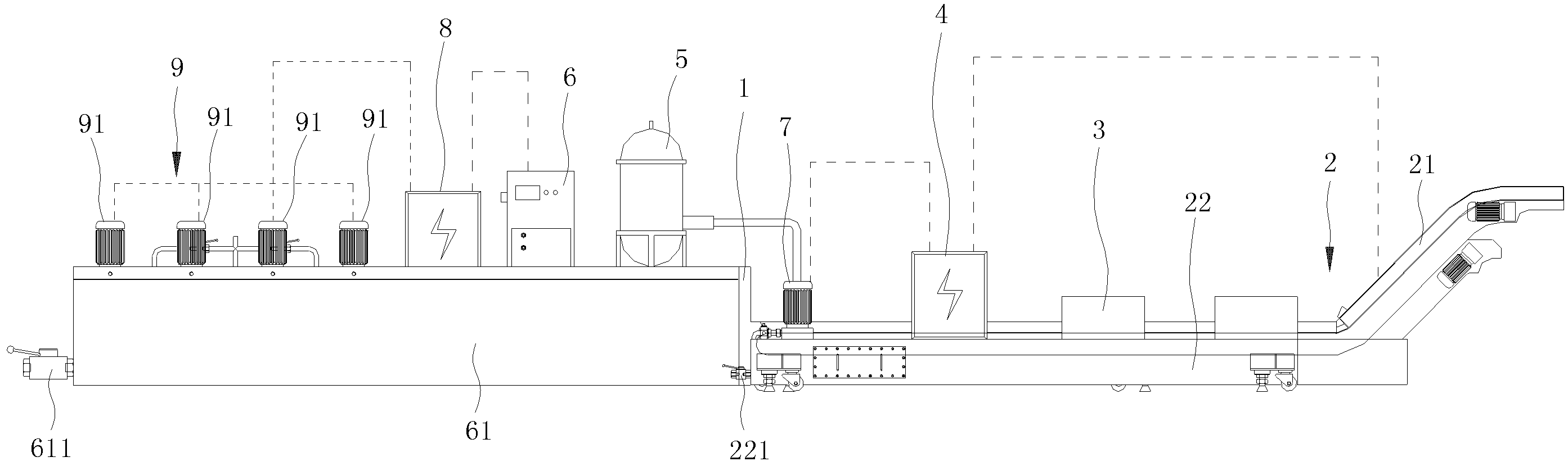

[0043] Please refer to figure 1 and figure 2 ,in figure 1 It is a front view schematic diagram of the overall structure of the chip removal cooling device of the scraping machine of the present invention, figure 2 It is a schematic plan view of the overall structure of the chip removal cooling device of the scraping machine of the present invention, as shown in the figure, the chip removal cooling device of the present invention mainly includes: a base frame 1; a chip removal unit 2, which is arranged on the base frame 1 and discharges Chip unit 2 receives the mixture of iron filings and coolant generated when the scraping mac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com