Machining online measurement method of blades of hydroturbine

A measuring method and water turbine technology, applied in the field of measurement, can solve the problems of difficult to determine the theoretical size of the processing part, difficult to determine the processing allowance, etc., and achieve the effects of reducing processing risks, reducing detection methods, and facilitating measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

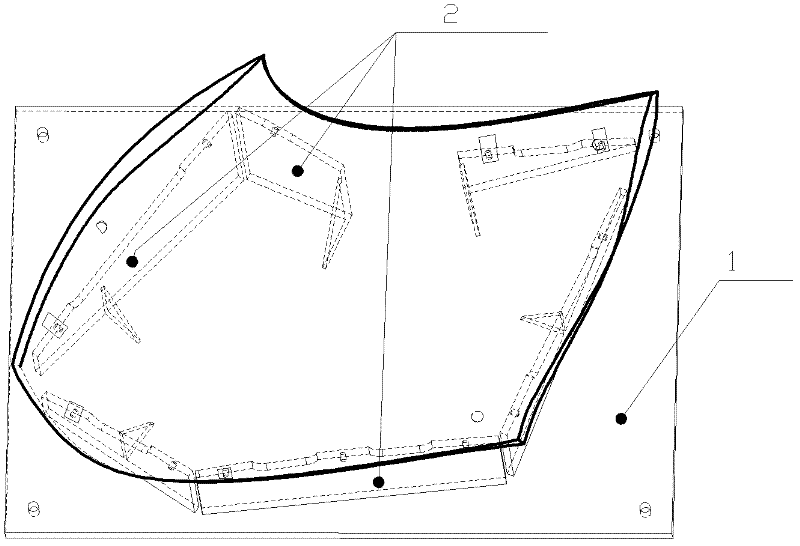

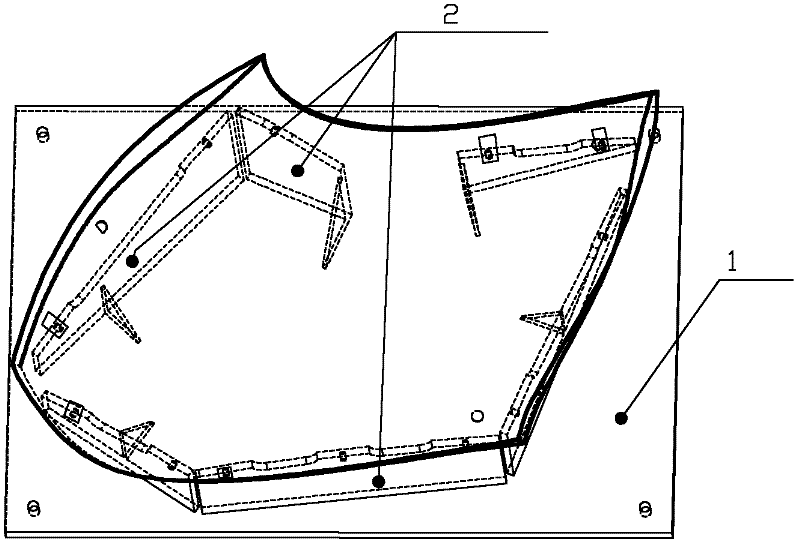

[0020] An on-line measurement method for machining blades of a water turbine is characterized in that the method includes the following steps:

[0021] a. Tooling design: According to the specific profile of the turbine blade and the specific processing range, processing width and height of the processing machine tool, the blade is adjusted to the required posture in the computer using 3D software, and then the special tooling is designed and rigidly connected with the blade Connection, to ensure the rigidity of the processing system, the origin of the coordinates of the processing system is set to the corner of the tooling, and make it the same as the origin of the processing program;

[0022] b. Detection: After the local processing is completed, use the machine tool to inspect 3~5 points on the processing surface of the blade and record the coordinate value of each point. Import each coordinate value into the 3D model to obtain the detection point. At this time, we measure t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com