Purification isolating device of aseptic powder needle split-charging production line

An isolation device and sterile powder injection technology, applied in the field of purifying isolation devices, can solve the problems of high construction cost, high maintenance cost, high cost, lack of human and medicine, and achieve the effect of solving the pollution problem and reducing the construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

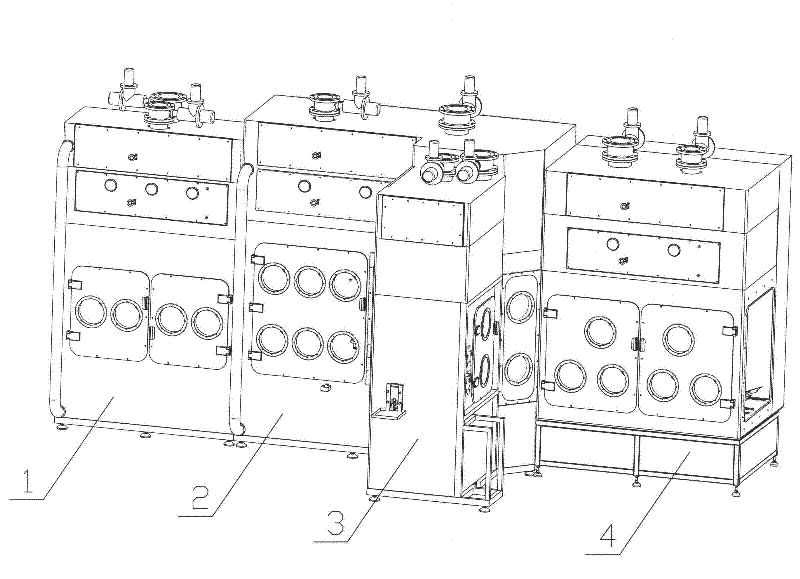

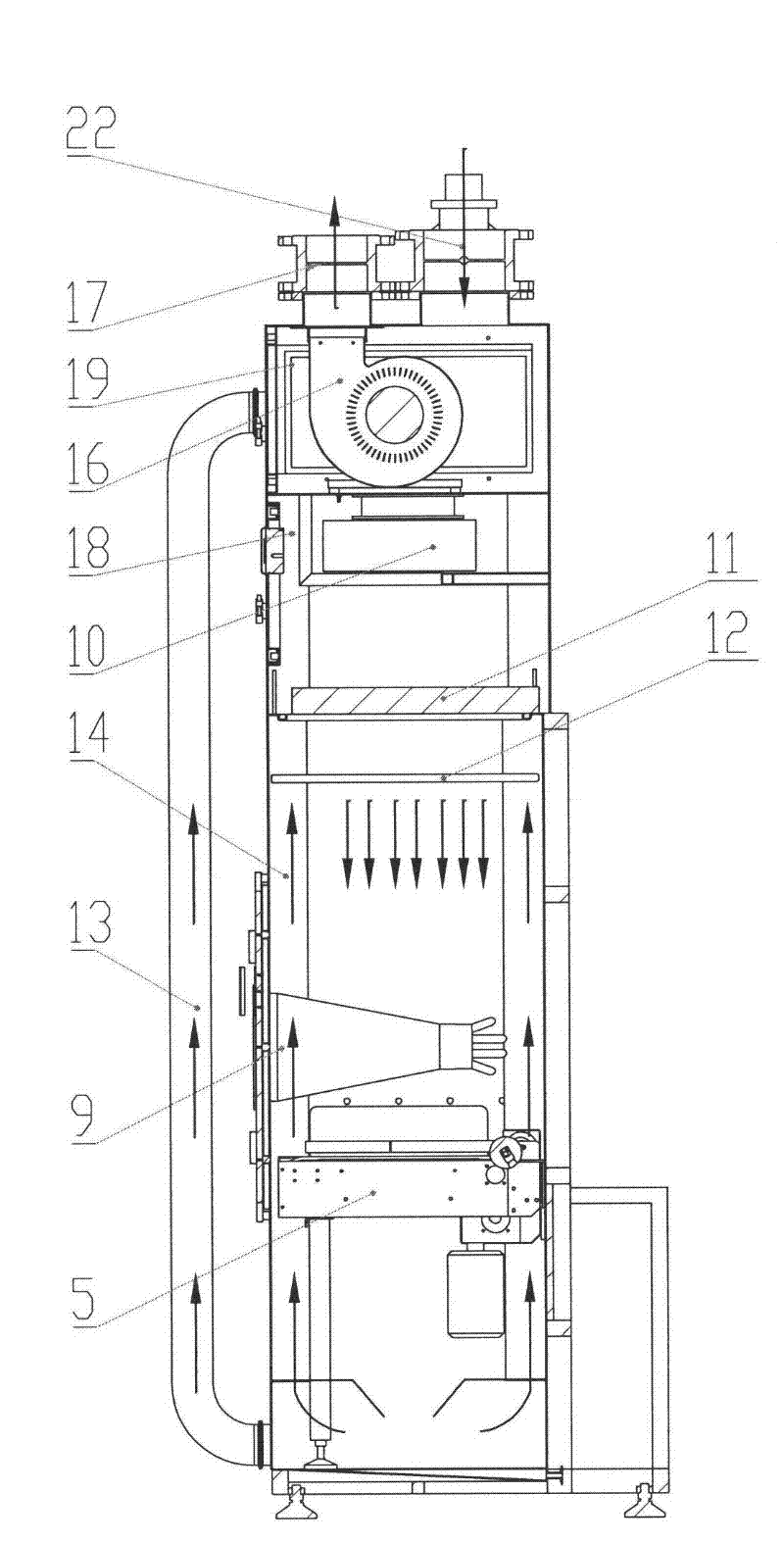

[0026] As shown in the figure, the purification and isolation device of the present invention includes an isolation device cabin, a bottle feeding buffer cabin, a filling and corking cabin, a capping cabin, a transfer cabin, an integrated interface board, a single laminar flow air supply system, and a return air system and exhaust system.

[0027] Among them, the left side of the bottle feeding buffer cabin is docked with the sterilization tunnel, and the right side of the transfer cabin is docked with the sterilization cabinet. The bottle feeding buffer cabin has a built-in bottle feeding machine, the filling and stoppering cabin has a built-in filling machine, and the capping cabin has a built-in capping machine. The transfer cabin is equipped with guide rails to connect with the guide rails in the sterilization cabinet to facilitate the entry and exit of the sterilization trolley. On the whole, the operation process of the production line is as follows: the external bottle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com