On-site crane car for power transformation engineering

A crane truck and on-site technology, applied to cranes and other directions, can solve problems such as hidden dangers of accidents, inability to use lifting equipment, and reduced power transmission and transformation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

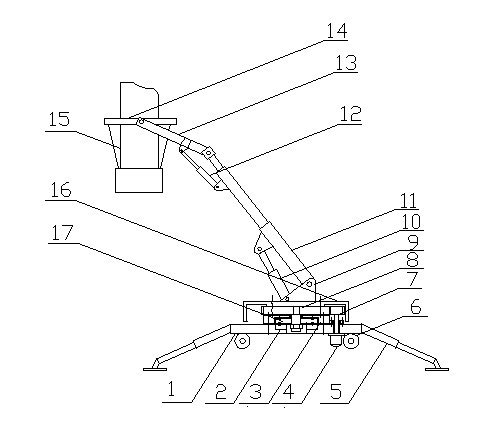

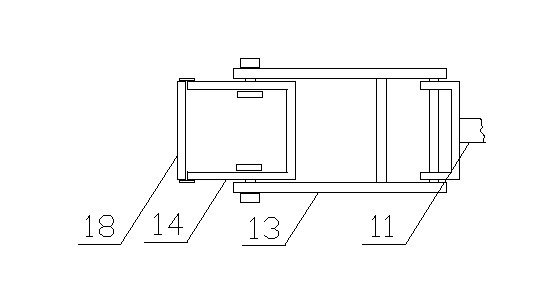

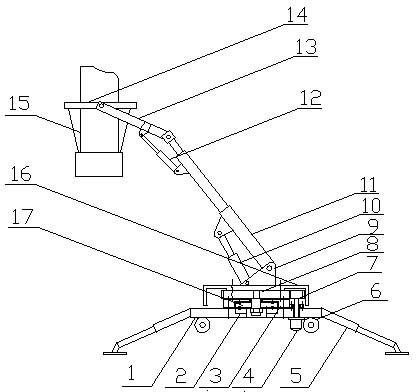

[0018] See figure 1 , figure 2 , The crane truck for substation engineering site of the present invention has a base 1 on which a rotating mechanism is provided. The rotating mechanism is composed of a lower fixed seat 2, an upper fixed seat 3, a lower turntable 17 and an upper turntable 8. , The lower fixing base 2 and the upper fixing base 3 are respectively fixedly mounted on the base 1 through fastening connectors. The lower turntable 17 is located between the lower fixing seat 2 and the upper fixing seat 3, and is respectively connected to the lower fixing seat 2 and the upper fixing seat 3 through ball and ball raceways or rolling grooves, and the upper turntable 8 passes through the upper fixing seat through the central axis 3 is fixedly connected with the lower turntable 17, so that the lower turntable 17 and the upper turntable 8 can rotate freely and lightly, so that the lifting boom 11 can rotate flexibly. The upper turntable 8 is provided with an outer ring gear, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com