Haulage winch

A winch and reel technology, applied in the direction of the hoisting device, the spring mechanism, etc., can solve the problems of small operating space, limited field of vision, and small axial operating distance for workers, and achieve convenient operation, improve operating environment, and operating space. increased effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

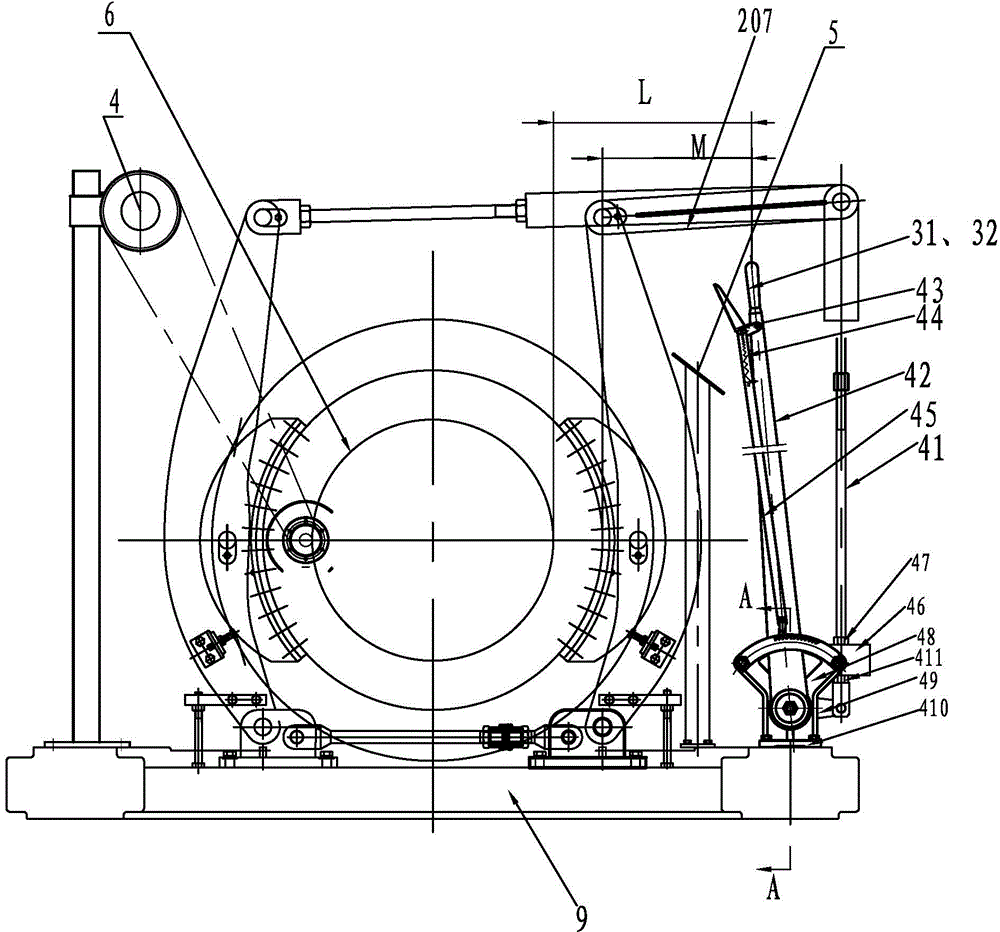

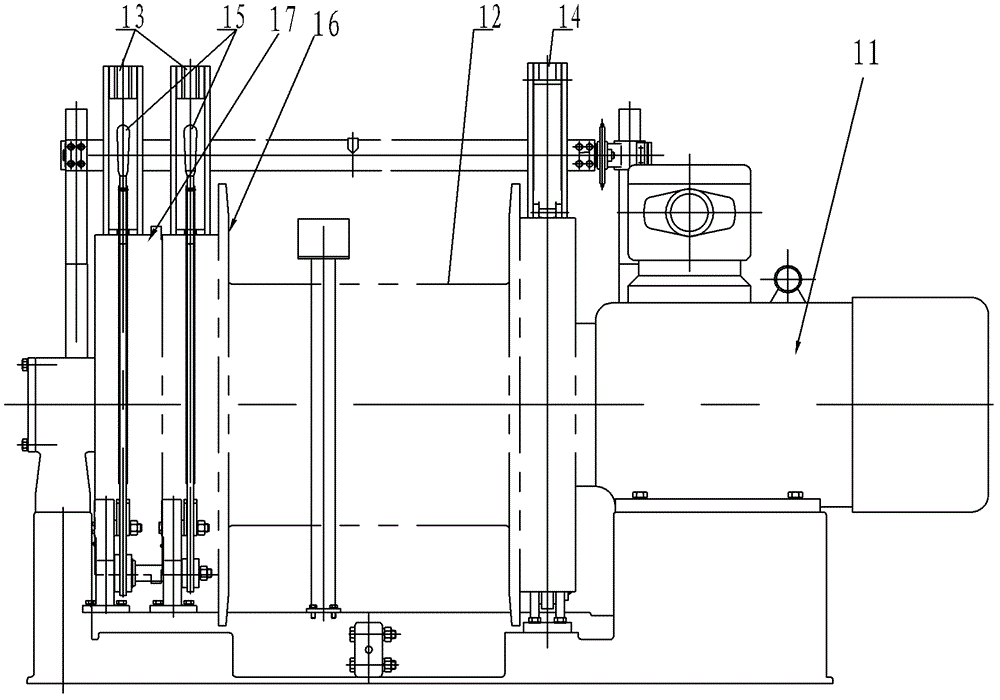

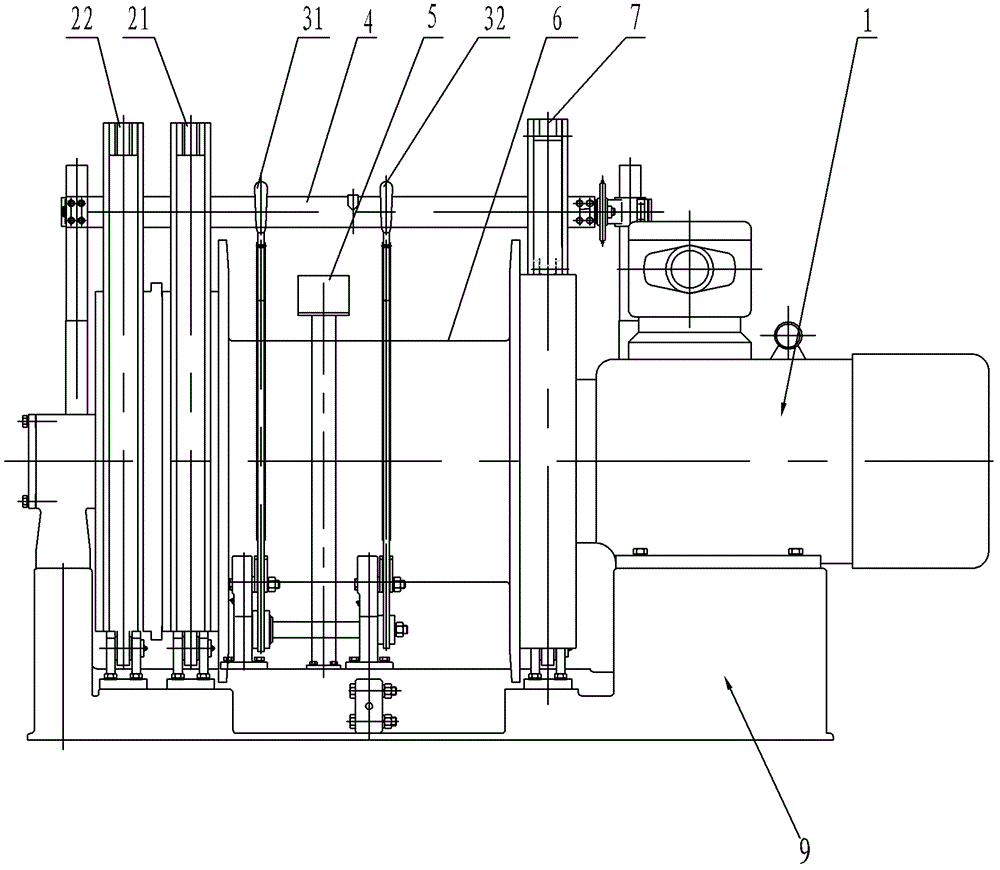

[0028] Such as figure 2 , 3 As shown, the transportation winch of the present invention includes a base 9, a motor 1, a reduction transmission system, a reel 6, a braking device, an operating device, a depth indicator 4, and a console 5. The base is designed in a symmetrical structure, and the motor is installed on the base 9 On the right, the output shaft of the motor is connected to the reel through a reduction drive system, which is set inside the reel.

[0029] Combine Figure 4 As shown, the reduction transmission system includes a primary planetary gear reduction mechanism 122, a secondary planetary gear reduction mechanism 123, and a lubrication system. One end of the output shaft 151 of the motor 1 extending into the reel 6 is equipped with a primary planetary gear reduction mechanism 122, and the planet carrier of the primary planetary gear reduction mechanism 122 is connected to the output shaft 124 of the secondary planetary gear reduction mechanism 123 through a gear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com