Method for preparing 4-ethoxy phenylacetic acid

A technology of ethoxybenzene and hydroxyphenylacetic acid, which is applied in the preparation of carboxylates, chemical instruments and methods, preparation of organic compounds, etc., can solve the problem of many by-products of chloromethylation, difficulty in product purification, and high pollution, etc. The problem is to achieve the effect of easy product purification, easy process realization and few by-products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

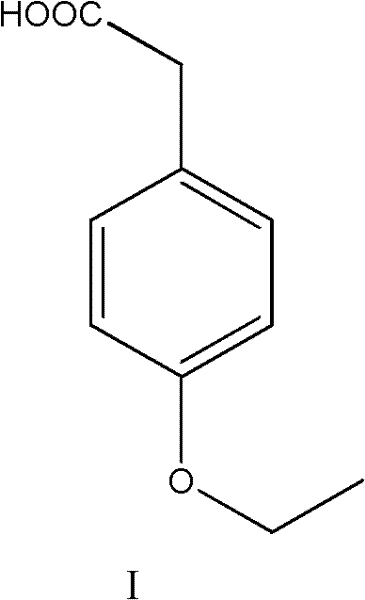

[0011] The invention provides a kind of method preparing the 4-ethoxyphenylacetic acid shown in general formula I, comprises the steps:

[0012]

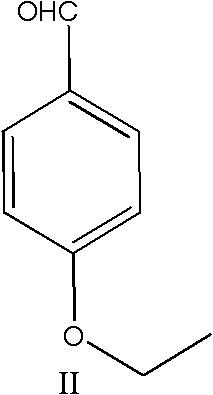

[0013] (1) Phenethyl ether and dimethylformamide react under the catalysis of phosphorus oxychloride to prepare 4-ethoxybenzaldehyde shown in general formula II;

[0014]

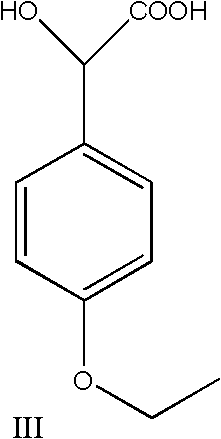

[0015] (2) The reaction of 4-ethoxybenzaldehyde (II) and chloroform under the action of a phase transfer catalyst prepares 4-ethoxyl-alpha-hydroxyphenylacetic acid shown in general formula III;

[0016]

[0017] (3) 4-ethoxy-α-hydroxyphenylacetic acid (III) undergoes hydrogenolysis reaction in the presence of a reducing agent to prepare 4-ethoxyphenylacetic acid represented by general formula I.

[0018] The feature of the reaction of phenetole and dimethylformamide in step (1) is aryl formylation, which includes the preparation of intermediate α-chloramine and the preparation of 4-ethoxybenzaldehyde by hydrolysis, wherein the hydrolysis conditions The ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap