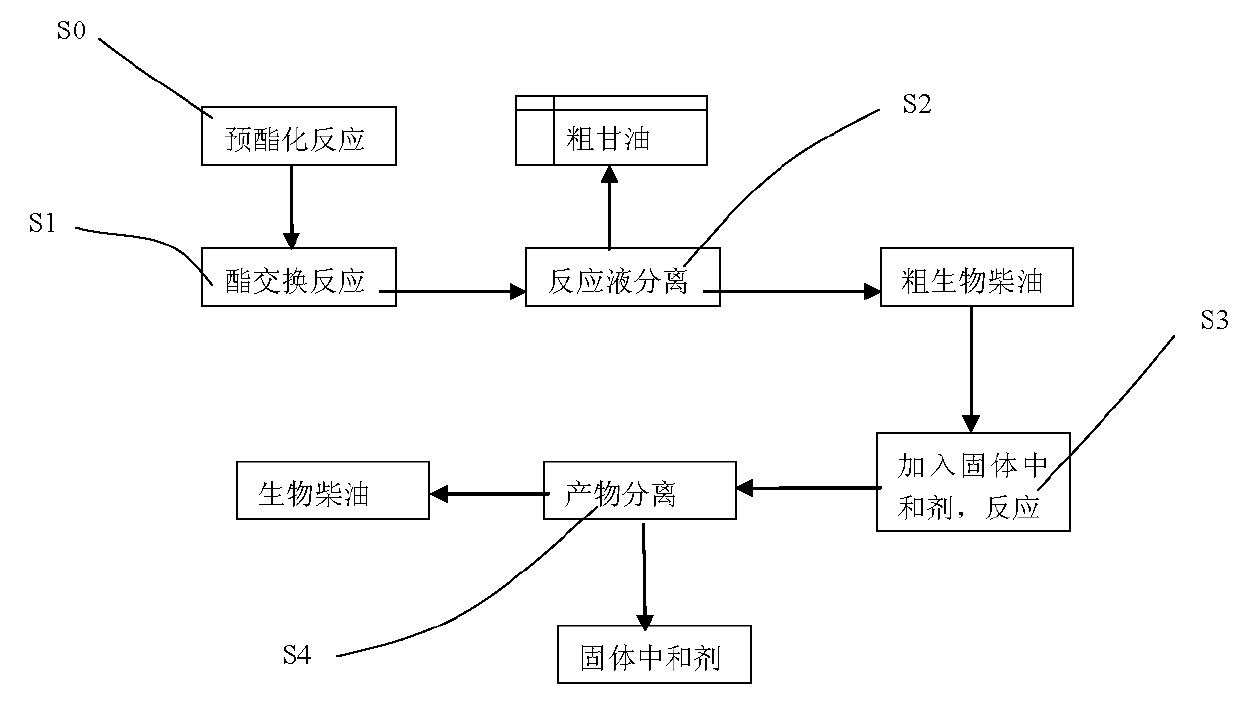

Biodiesel production method

A biodiesel and production method technology, applied in biofuel, petroleum industry, liquid carbon-containing fuel, etc., can solve the problems of high reaction temperature, high price, high alcohol-oil ratio, etc., and achieve mild reaction conditions, no waste water discharge, High conversion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] In a 2000ml three-necked flask, add 800g of corn oil and 132.27g of methanol to mix according to the molar ratio of alcohol to oil at 6:1, then add 53.33g of methanol-sodium hydroxide solution with a concentration of 15%, and stir at 60°C After reacting for 40 minutes, the reaction was completed, and then poured into a separatory funnel to stand for stratification. The upper layer was crude biodiesel, and the lower layer was crude glycerol, a by-product. After separating the crude glycerin, the excess methanol was evaporated to obtain crude biodiesel. Then add 38.4g of solid neutralizing agent—acid clay to the crude biodiesel, stir and react for 30 minutes, and separate the solid neutralizing agent—acid clay to obtain the product biodiesel. Yield 96.7%.

Embodiment 2

[0027] In a 2000ml three-neck flask, add 1200g of rapeseed oil and 198.4g of methanol according to the molar ratio of alcohol to oil at 6:1, mix them, add 80g of methanol-sodium hydroxide solution with a concentration of 15%, and stir at 60°C After reacting for 40 minutes, the reaction was completed, and then poured into a separatory funnel to stand for stratification. The upper layer was crude biodiesel, and the lower layer was crude glycerol, a by-product. After the crude glycerin was separated, excess methanol was evaporated to obtain crude biodiesel. Then add 45.7g of solid neutralizer—a mixture of modified zeolite molecular sieve and acid clay at a ratio of 1:3 (mass ratio) to the crude biodiesel, stir and react for 30 minutes, and then separate the modified zeolite molecular sieve and acid clay to obtain the product biodiesel. Yield 95.3%.

Embodiment 3

[0029] In a 1000ml three-neck flask, add 610g of cottonseed oil and 100.87g of methanol according to the molar ratio of alcohol to oil at 6:1 and mix them. Add 40.67g of methanol-potassium hydroxide solution with a concentration of 15%, and stir at 60°C After reacting for 45 minutes, the reaction was completed, and then poured into a separatory funnel to stand for stratification. The upper layer was crude biodiesel, and the lower layer was the by-product crude glycerin. After the crude glycerin was separated, excess methanol was distilled off. Then add 23.1g of solid neutralizer—a mixture of modified zeolite molecular sieve and strong acid resin at a ratio of 1:1 (mass ratio) to crude biodiesel, and stir for 30 minutes to separate the modified zeolite molecular sieve and strong acid resin. The product biodiesel is obtained. Yield 94.6%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com