Graphite boat cooling and chip unloading trolley

A technology of graphite boats and sheet carts, which is applied in the direction of gaseous chemical plating, metal material coating technology, coating, etc., can solve the problems of space movement and time waste, and achieve the goals of reducing circulation time, convenient operation, and saving space Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

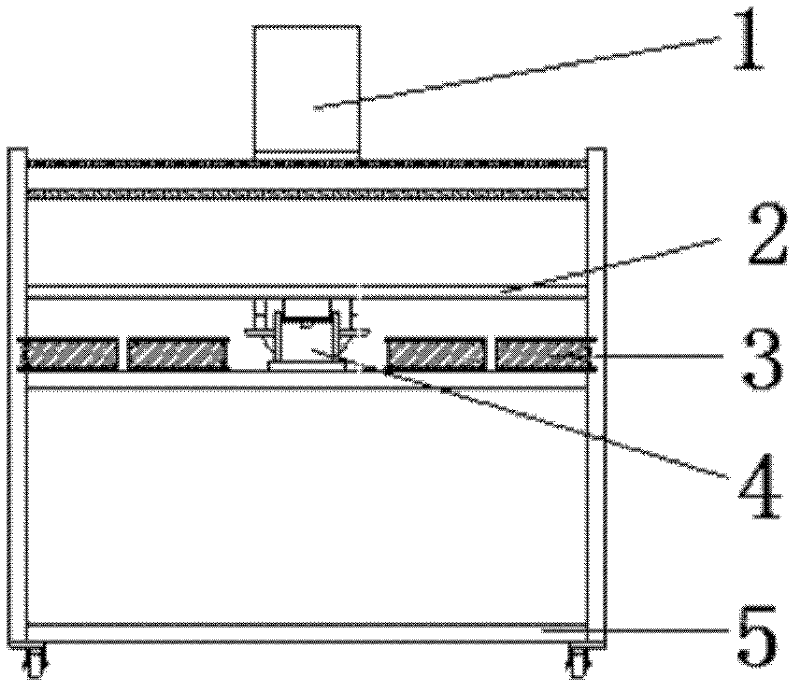

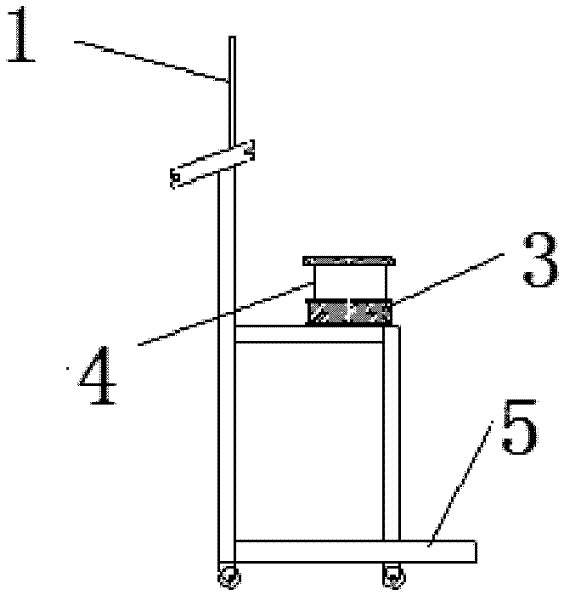

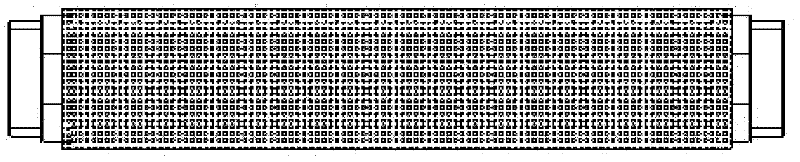

[0014] Embodiment 1: as figure 1 , figure 2 , image 3 As shown, the unloading platform of the graphite boat cooling and unloading trolley has an overall steel bracket 5, and the graphite boat support plate 2 is connected as a whole through a fixed bracket 4, and four cooling plates are fixed under the graphite boat support plate. The device 3 is equipped with a flower basket support 1 on the top of the trolley for placing the unloading flower basket, and can move left and right to ensure the convenience of inserting work.

[0015] A cooling and unloading trolley, which is composed of an overall support bracket, a graphite boat support plate, a flower basket bracket, a cooling device and a fixed support. The cooling device is installed. After the high-temperature graphite boat is taken out of the furnace tube, it is placed on the unloading table , can meet the purpose of cooling graphite boat and silicon wafer, and can also play multiple functions of transfer car and unload...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com