Construction method for spherical curved surface stainless steel curtain wall

A spherical curved surface and stainless steel technology, applied to walls, building components, buildings, etc., can solve the problems of difficult cleaning of glass curtain walls, high cost of titanium metal plates, and failure to meet requirements, so as to shorten the construction period, save engineering costs, and improve construction efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] After completing the main structure of the building, start to carry out the construction of the stainless steel curtain wall of the present invention, and its construction steps include: 1. Construction setting out; 2. Operating scaffold erection; 3. Steel support installation; 4. Steel keel installation; galvanized iron sheet lining installation; 6. Fireproof layer construction; 7. Insulation layer construction; 8. Waterproof aluminum plate installation 9; Aluminum alloy keel support installation; 10. Hyperboloid stainless steel panel installation; 11. Glue injection; . Sound-absorbing layer construction. The following is attached Figure 1 A note:

[0044] 1. Construction setting out:

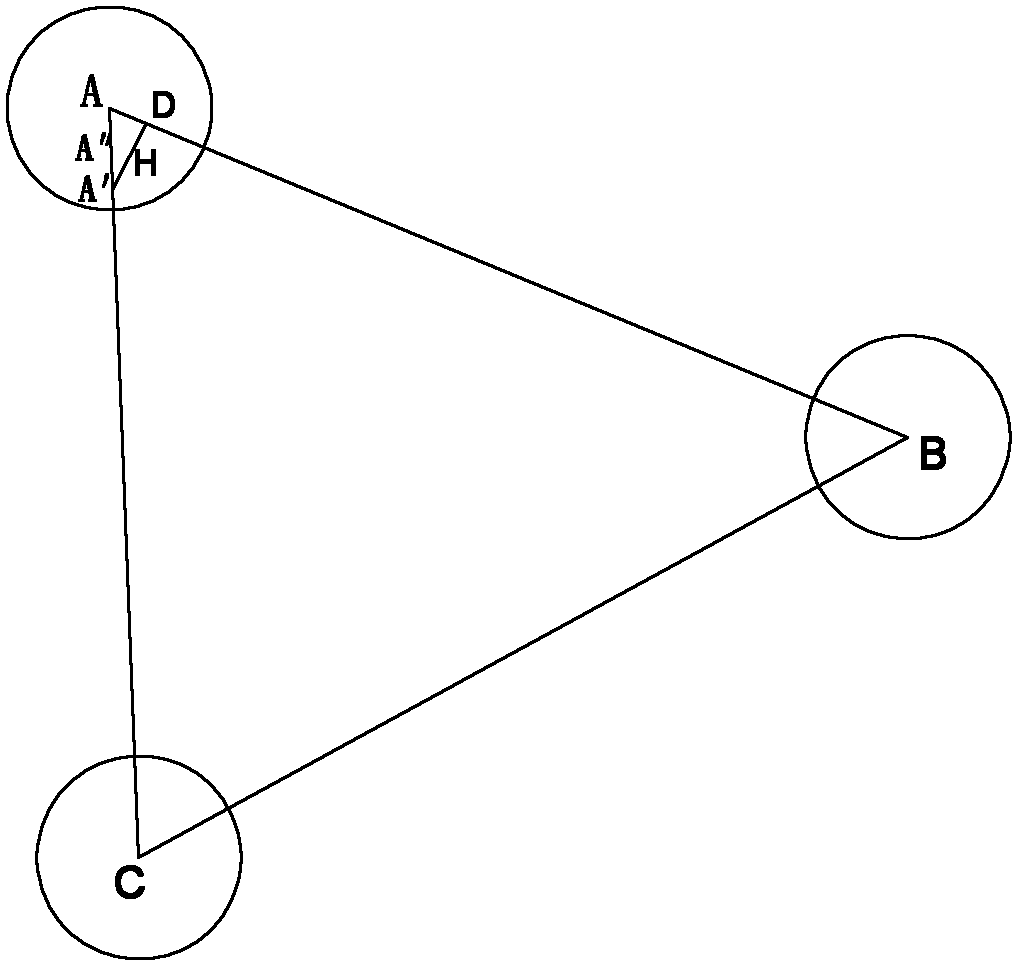

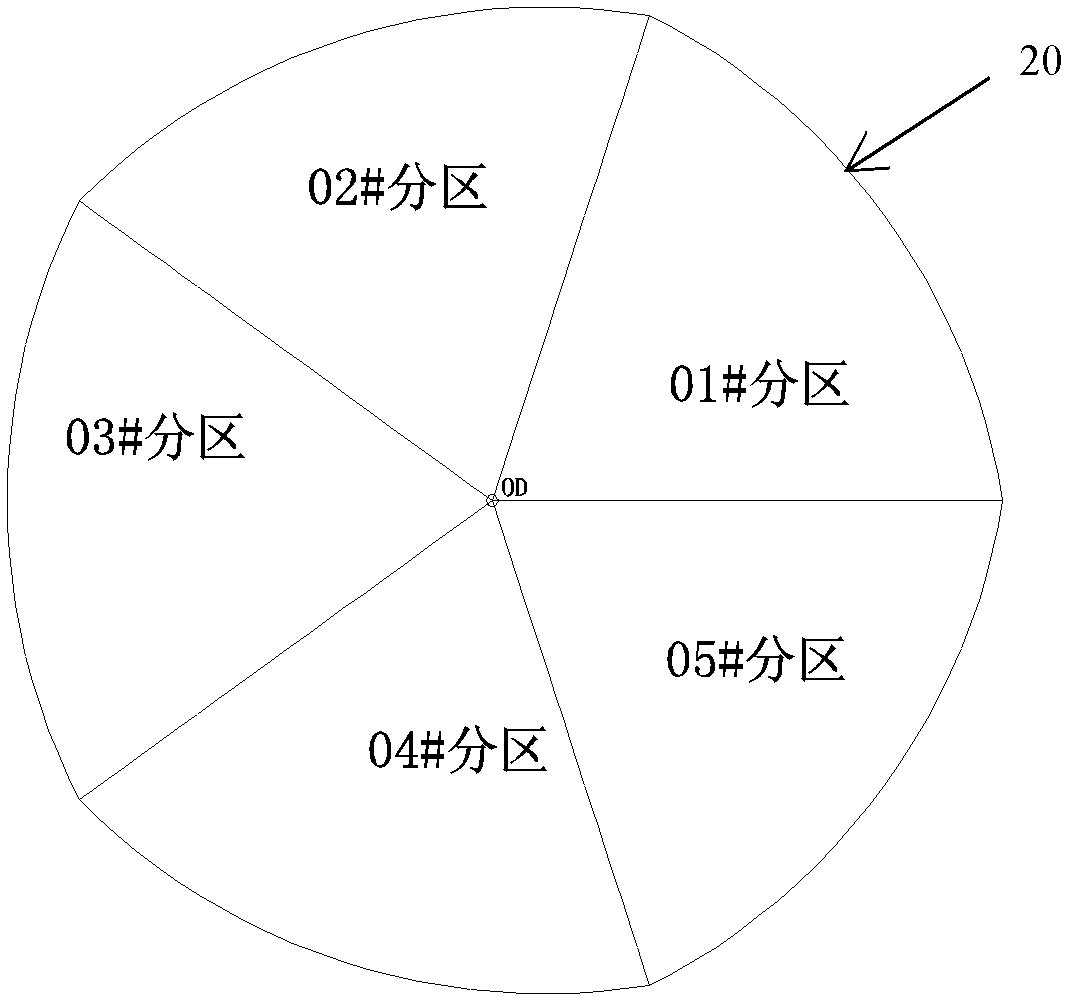

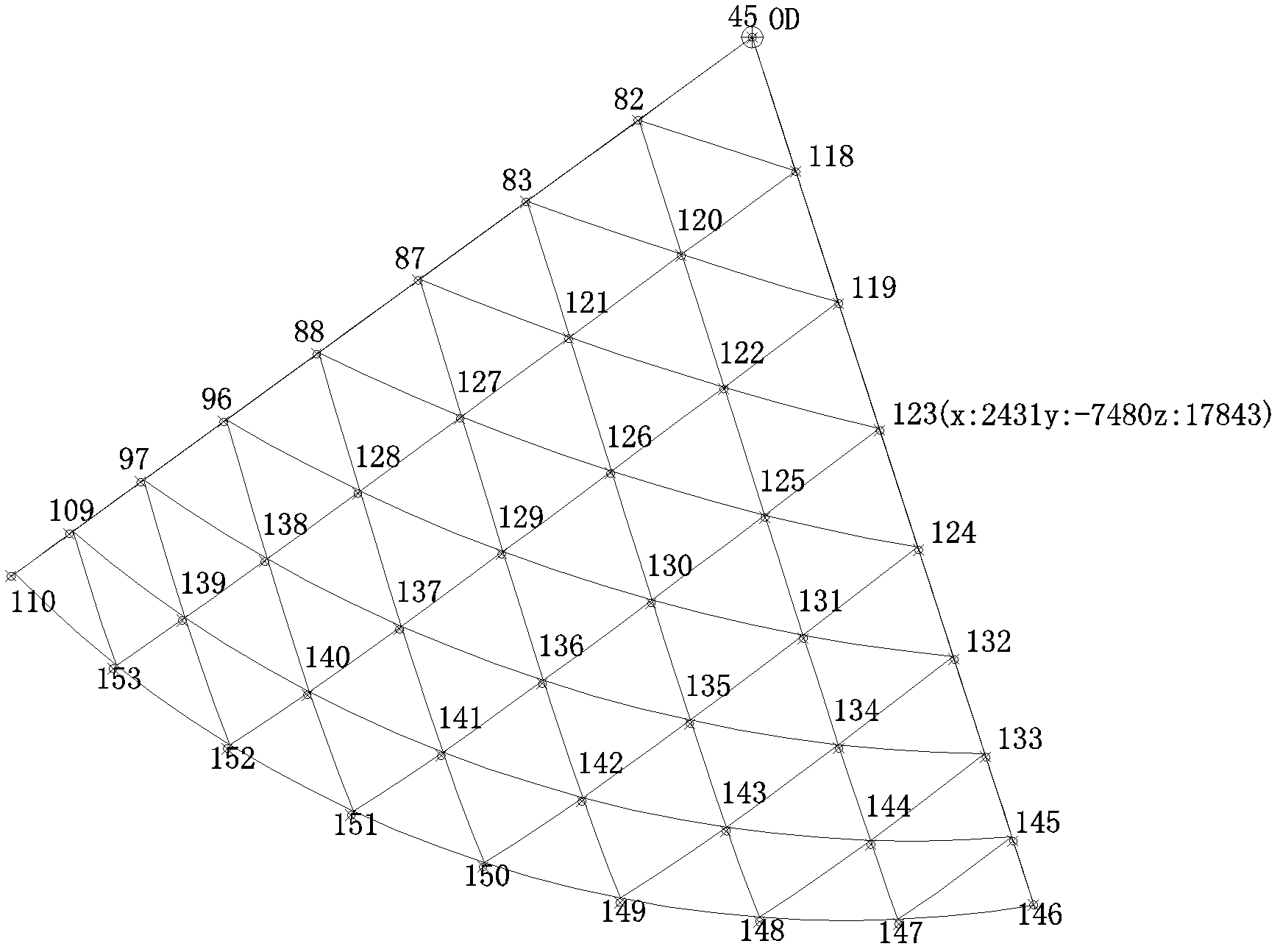

[0045] (1) First use the total station to measure the data of the elements of the real spherical surface, use the real spherical surface and the theoretical spherical surface to perform the best fitting, find out the spatial deviation of the points, and provide a basis for subsequent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com