Ultrasonic lens electrode manufacturing method for effectively reducing acoustic parasitic signal

A technology of parasitic signal and production method, which is applied in the direction of material analysis, scientific instruments, and measuring devices using sonic/ultrasonic/infrasonic waves, which can solve the problem of reducing the excitation intensity of sound field radiation, reducing the ultrasonic high-frequency performance of ultrasonic lens design, and the limited space of the lens. Crowding and other problems, to reduce the generation and scattering of additional complex sound sources, improve the quality of microscopic imaging, and facilitate accurate spatial positioning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

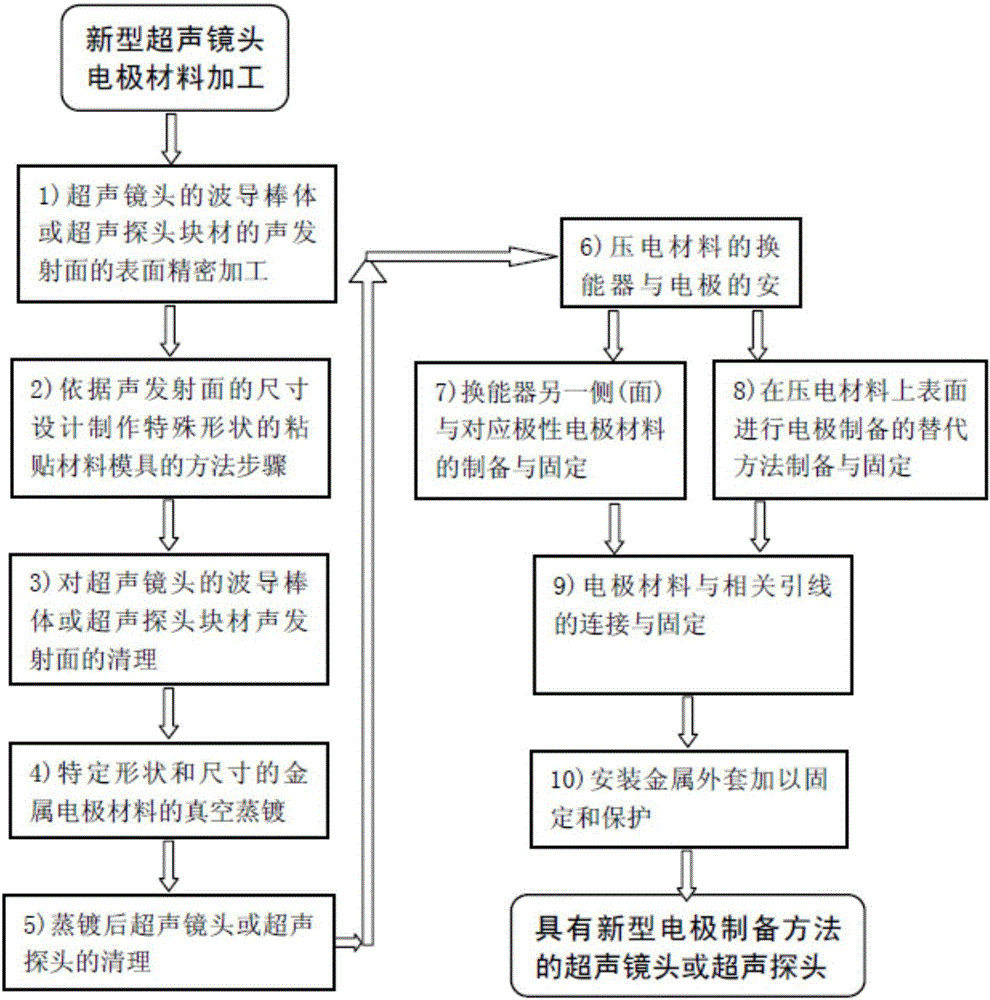

[0045] 4) Preparation and process control of electrode materials with specific shapes and thicknesses;

[0046] 5) Cleaning the evaporated ultrasonic lens or probe and the generated electrode material;

[0047] 6) Install and fix the ultrasonic transducer on the electrode material;

[0048] 7) Preparation and fixation of the electrode material corresponding to the polarity on the other side of the ultrasonic transducer;

[0049] 8) Connection and fixation of the electrode material and its related lead wires;

[0050] 9) The metal jacket is fixed and protected.

[0051]In said step 1, various solid materials such as quartz rods or high molecular polymers are selected as materials for making ultrasonic lenses or acoustic probes, processed into block shapes such as cylindrical rods and wedges, and the rods or blocks are One of the sides is used as the acoustic emission end face, after fine grinding, grinding and other processes to ensure the smoothness ▽≥10.

[0052] In the s...

specific Embodiment

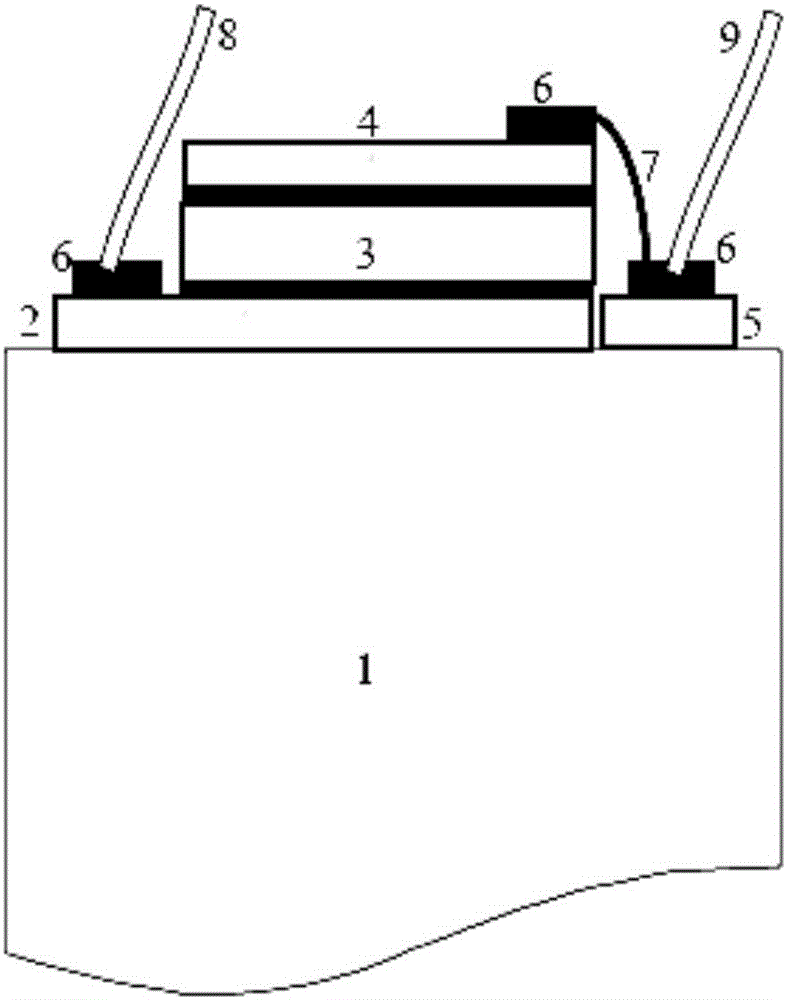

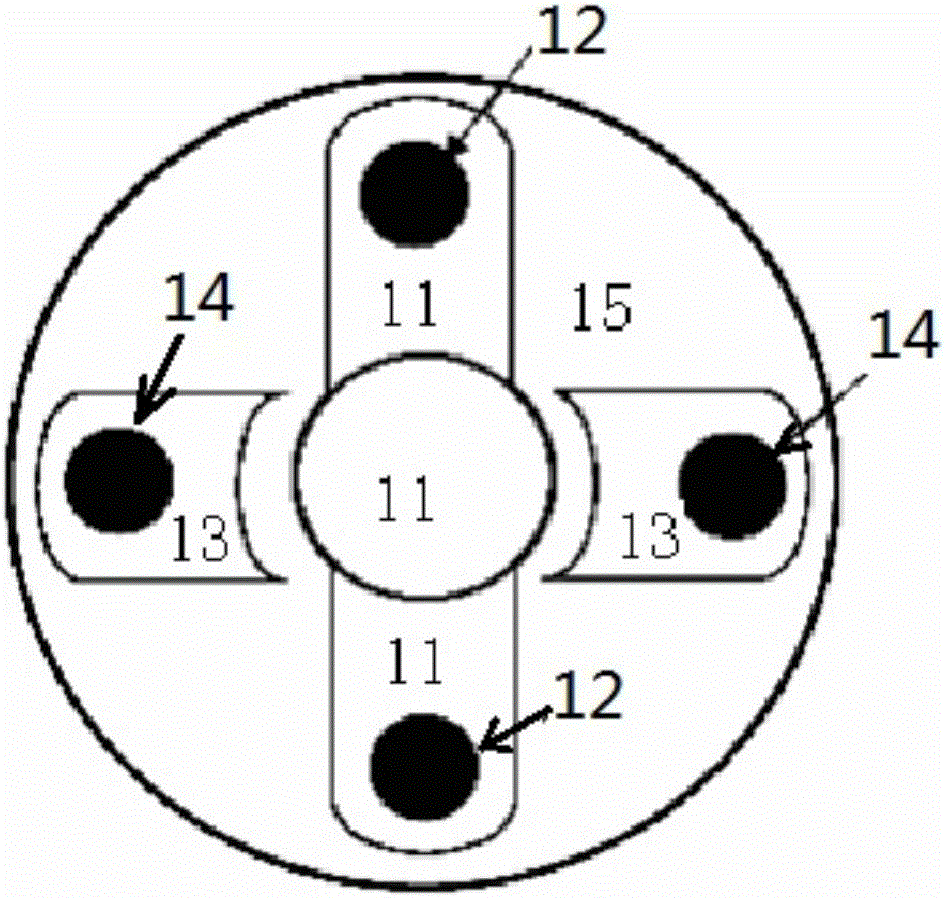

[0127] figure 2 , image 3 Shown is the physical map of the ultrasonic lens obtained through the aforementioned related methods and specific steps. figure 2 A side view entity diagram of the longitudinal rigid connection of the electrode and its attached lead wires with the ultrasonic lens to the rod or ultrasonic probe block is given; image 3 The shape or spatial distribution of the electrode material is given in , which is generally spread out in a cross, and is distributed on the acoustic emission surface of the ultrasonic lens waveguide to the rod or ultrasonic probe block. The combination of the two images provides a complete solution, which can facilitate the production of various ultrasound lenses or ultrasound probes.

[0128] image 3 In , the vapor-deposited electrodes are distributed symmetrically up, down, left, and right. The part symmetrically distributed up and down (labeled 11) is used as the bottom lead-out electrode of the piezoelectric material, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com