Machine tool for repairing surface of die

A technology of molds and machine tools, which is applied in the field of machine tools for repairing the surface of molds, and can solve the problems of short mold life, low manufacturing precision, waste of resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. The schematic embodiments and descriptions of the present invention are used to explain the present invention, but not as a limitation to the present invention.

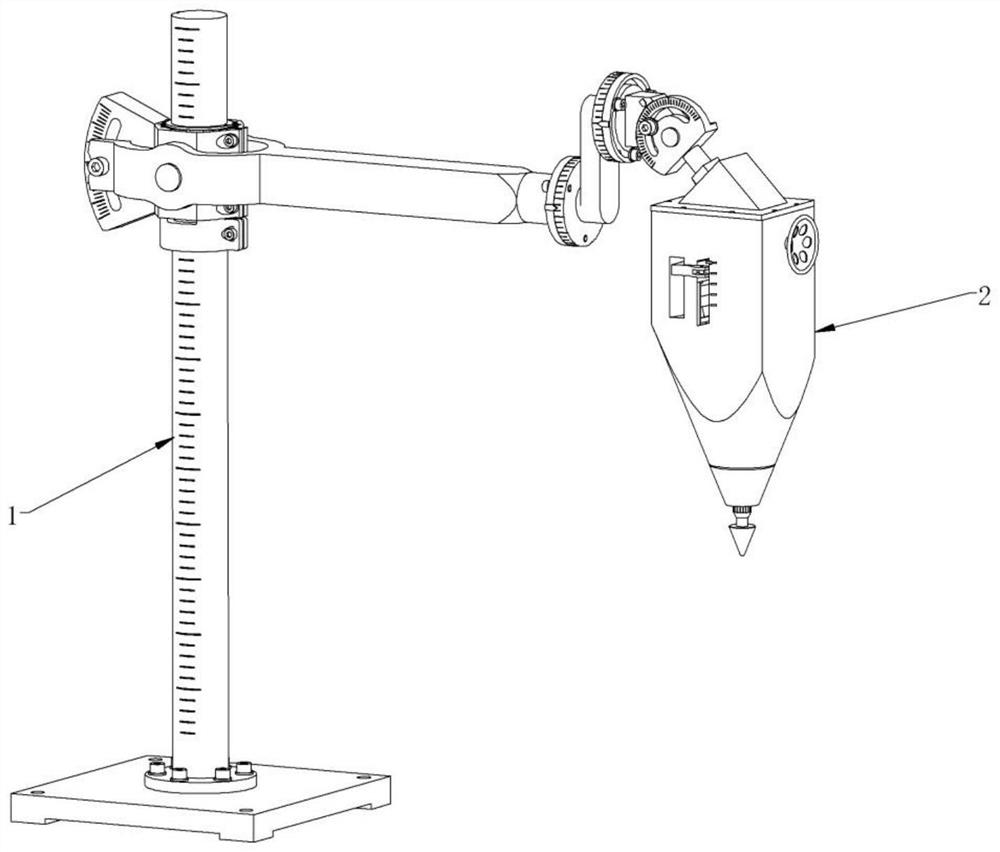

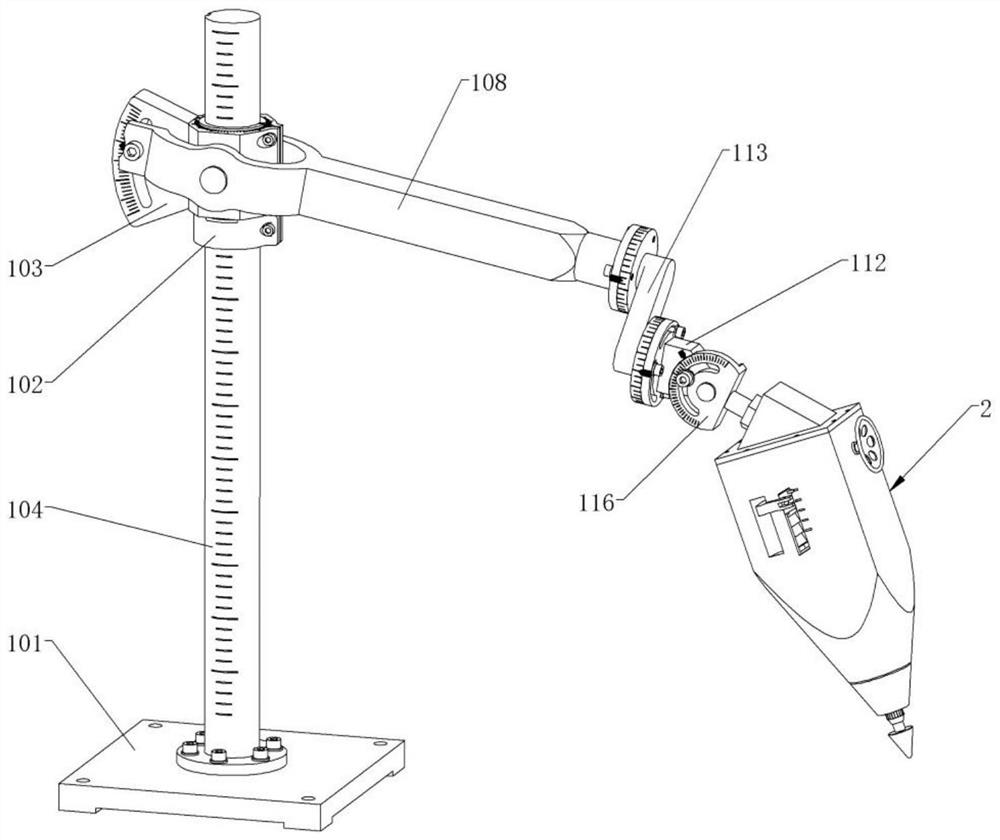

[0049] Such as figure 1 , figure 2 As shown, the machine tool for repairing the surface of the mold includes a positioning frame mechanism 1 and a trimming head mechanism 2. It is characterized in that: the positioning frame mechanism 1 has six degrees of freedom in space, and each movable joint is provided with a scale. The trimming head mechanism 2 adopts The five-speed transmission is fastened to the end of the positioning frame mechanism 1, and is used for repairing the surface of the mold.

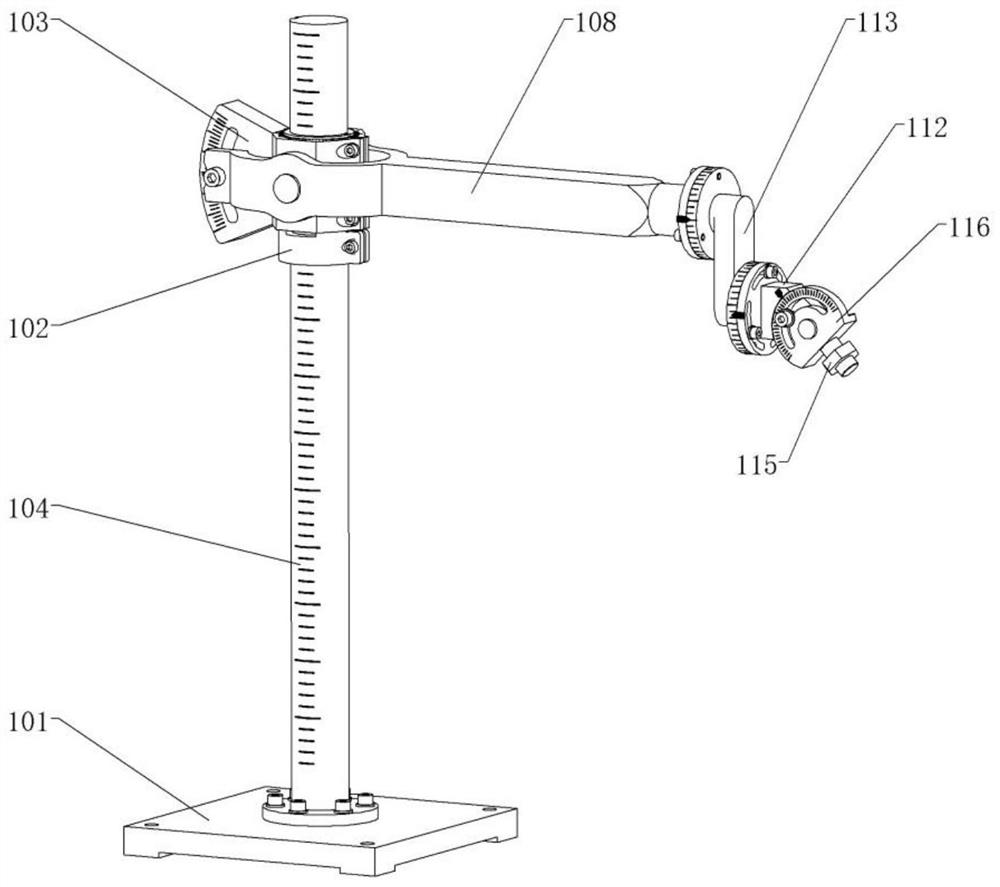

[0050] Such as Figure 3 to Figure 6 As shown, the positioning frame mechanism 1 includes a base 101, a positioning sleeve 102, a sliding sleeve 103, a column 104, a second screw 105, a poin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com