Air treatment unit for automotive compressed air system

An air processing unit and compressed air technology, which is applied in the direction of fluid pressure actuation system components, fluid pressure actuation devices, mechanical equipment, etc., can solve the problems of high cost of magnetic valves, increased cost and space requirements, and achieve energy saving, Effect of high air consumption, good adjustability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

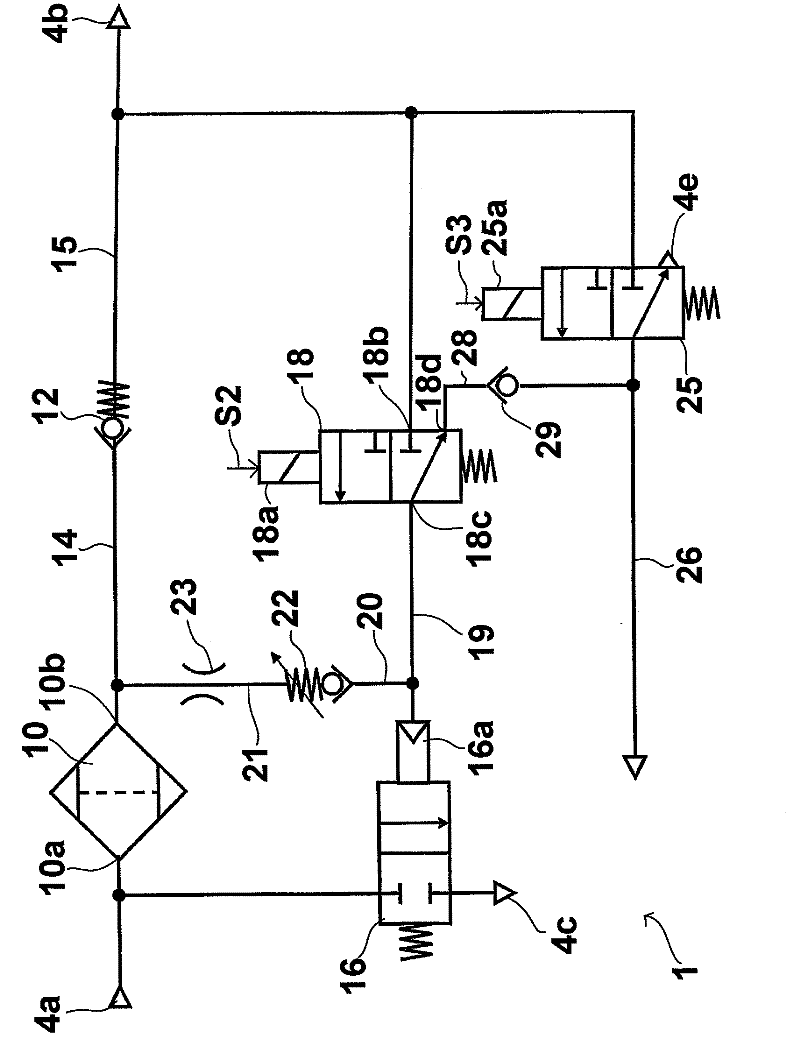

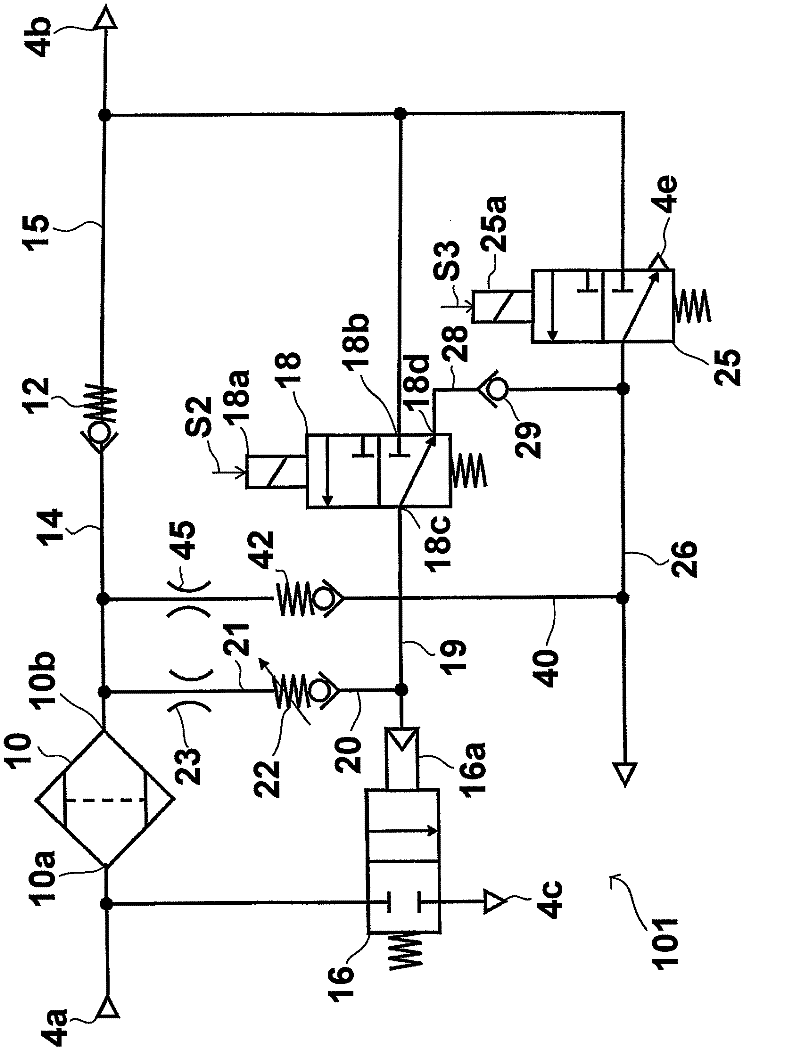

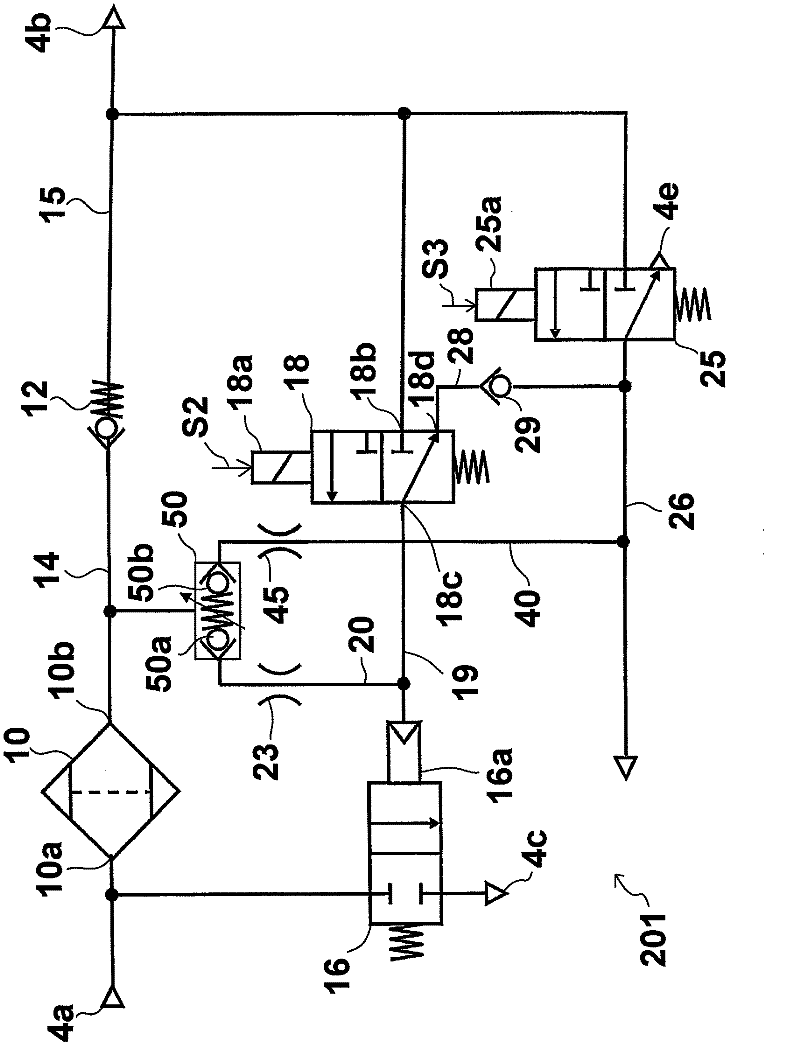

[0030] exist figure 1 The air handling unit 1 shown in the Figure 4 Used in the compressed air system 2 of the vehicle. The air treatment unit 1 has a compressed air input 4a for connection to a compressor 3 and a compressed air output 4b for connection to a multi-circuit protection valve 5, a plurality of consumer circuits 6a, 6b, 6c, 6d as Consumer devices are connected to the multi-circuit protection valve, the consumer circuits each having, for example, a compressed air storage container for temporarily storing the supplied compressed air. The compressor 3 runs on the motor shaft 8 and has a pneumatic control input 3 a by means of which the delivery operation of the compressor can be terminated when pressure is applied and thus an idling operation is present.

[0031]Furthermore, the compressor 3 can be switched between delivery operation and rest operation of the compressor 3 via the first electrical control signal S 1 of the control device 7 ; according to the inventi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com