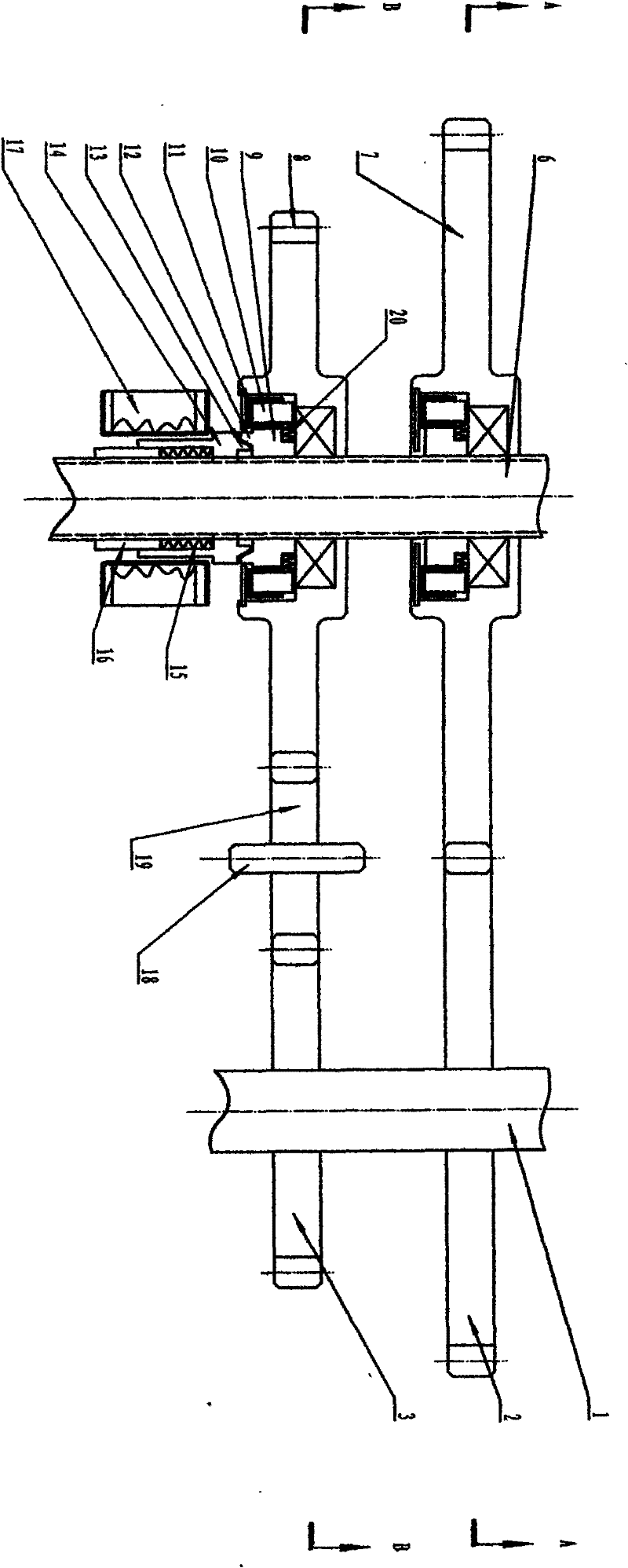

Positive-operation inversion-transcending gear-changing mechanism

A reverse, working technology, applied in mechanical equipment, gear transmission, belt/chain/gear, etc., can solve the problems of difficult repair, slow response to speed changes, limited bearing torque, etc., to achieve simple and novel structure, simple structure, Easy to maintain effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

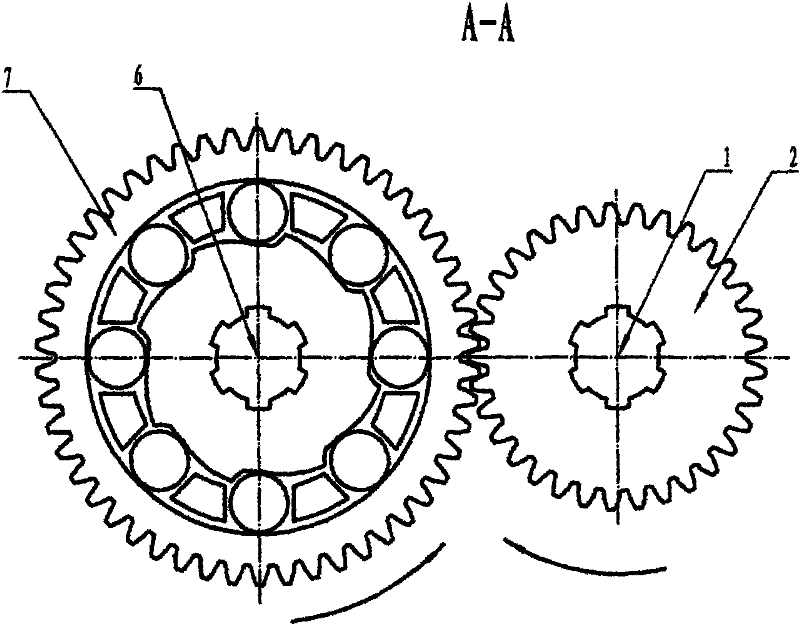

Embodiment 1

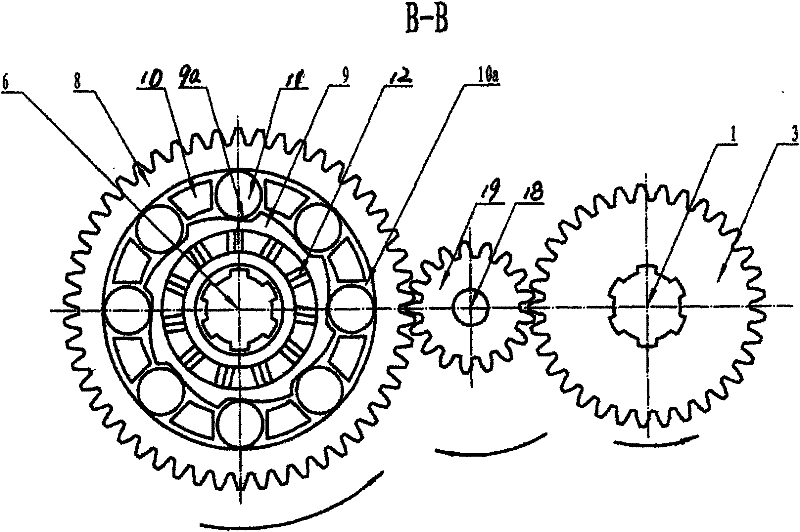

[0013] please join image 3 : the first-gear driven single-reciprocator includes a first-gear driven gear 8 meshing with the first-gear driving gear 3, and the left part of the first-gear driven gear 8 is mounted on the driven shaft 6 via a bearing, A gear driven cam 9 is installed at the center of the right part of the first gear driven gear 8, and the first gear driven cam 9 is looped on the driven shaft 6. Between the first gear driven cam 9 and the first gear slave A gear driven floating sleeve 10 is installed between the inner walls of the driven gear 8, and a group of first gear driven cam curved surfaces 9a are arranged on the outer circumference of the first gear driven cam 9, and the first gear driven cam curved surfaces 9a are uniform. Distributed on the outer circumference of the first gear driven cam 9, the first gear driven cam curved surface 9a is a smooth curved surface with lift characteristics, and each first gear driven cam curved surface 9a is distributed co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com