Large-caliber corrugated pipe comprising spiral-spring pipe framework and manufacturing method

A production method, the technology of snake reed pipe, applied in the direction of pipes/pipe joints/fittings, hoses, pipes, etc., can solve the problems of bellows strength reduction, bellows collapse, inner polyethylene damage, etc., and improve adaptability , avoid disengagement, and improve the overall anti-pressure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

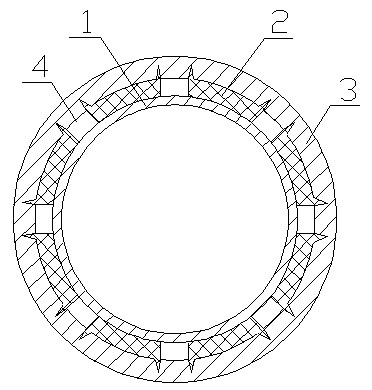

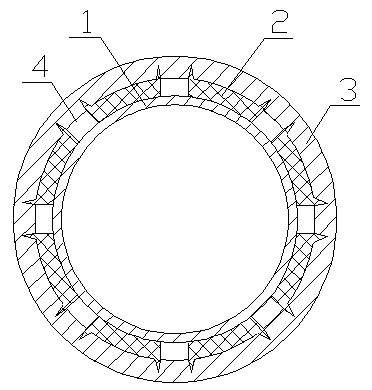

[0009] Embodiment 1: with reference to attached figure 1 . A large-diameter corrugated pipe composed of a snake-reed pipe skeleton, which includes an inner pipe 1, a snake-reed pipe 2 compounded on the inner pipe 1, and the inner wall of the snake-reed pipe 2 is bonded to the outer wall of the inner pipe 1, and the two sides of the snake-reed pipe are A plastic layer 3 is placed on it. A plurality of dovetail holes 4 are punched on the surface of the snake reed pipe 2, and the rims of the dovetail holes 4 form a circle of holes. The snake reed pipe is made of steel strip or aluminum strip.

Embodiment 2

[0010] Example 2: On the basis of Example 1, a method for manufacturing a large-diameter corrugated pipe composed of a snake-reed pipe skeleton, the snake-reed pipe is concentrically placed in the large-diameter polyolefin winding growth pipe production line manufactured by the applicant On the bellows core and the coil spring tube and the bellows core are matched at a distance, and then the large-caliber polyolefin winding growth tube production line manufactured by the applicant is used in the process of making the inner tube of the bellows, and the production line is used to make the inner tube. During the melting and forming process of the inner tube, the plastic is melted and bonded with the inner wall of the coiled reed tube, and after cooling, the coiled tube and the outer wall of the inner tube are integrated. Composite on the outer wall of the snake reed pipe, cooling and forming. A plurality of dovetail holes 4 are punched on the surface of the snake reed pipe 2, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com