Backlight module and liquid crystal display device

A technology of backlight module and back frame, which is applied in lighting devices, fixed lighting devices, components of lighting devices, etc., can solve problems affecting the display performance of liquid crystal display devices, complex processes, positioning errors, etc., and improve the efficiency of repeated use , maintenance cost reduction, the effect of reducing the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

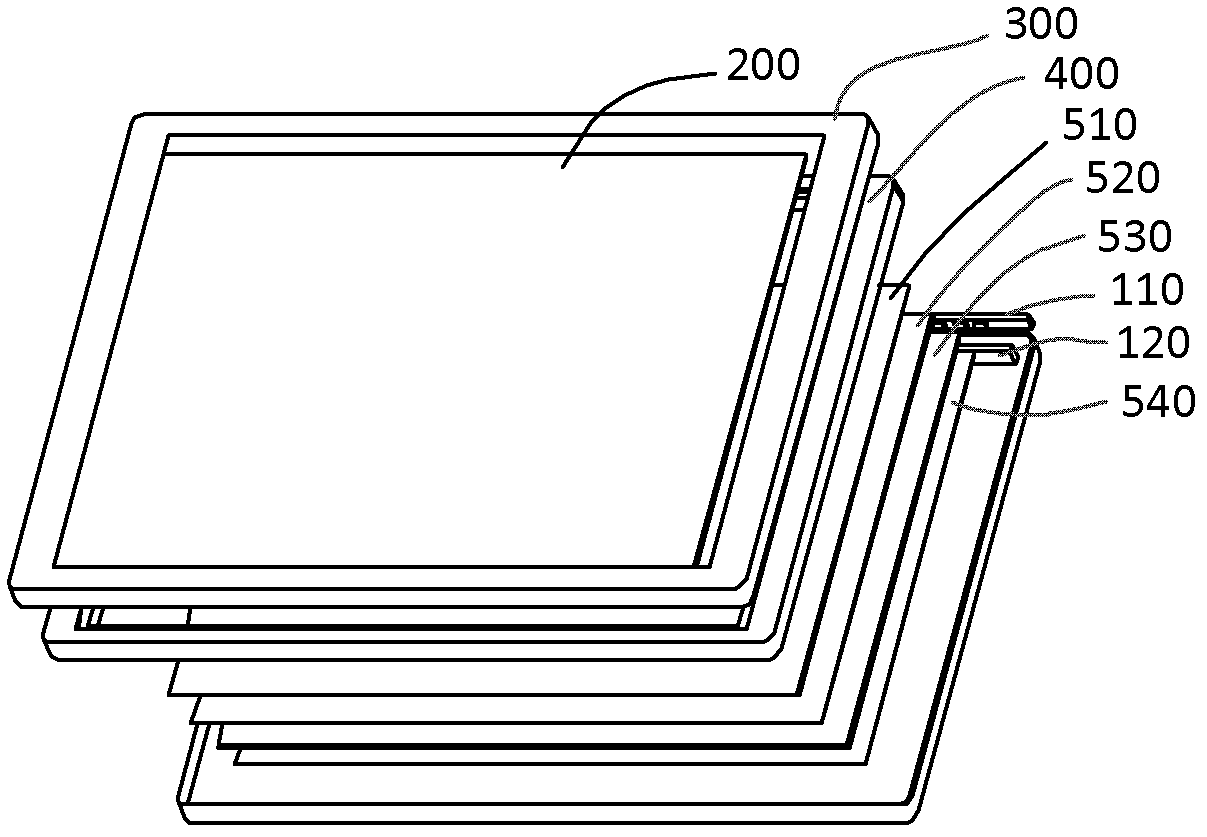

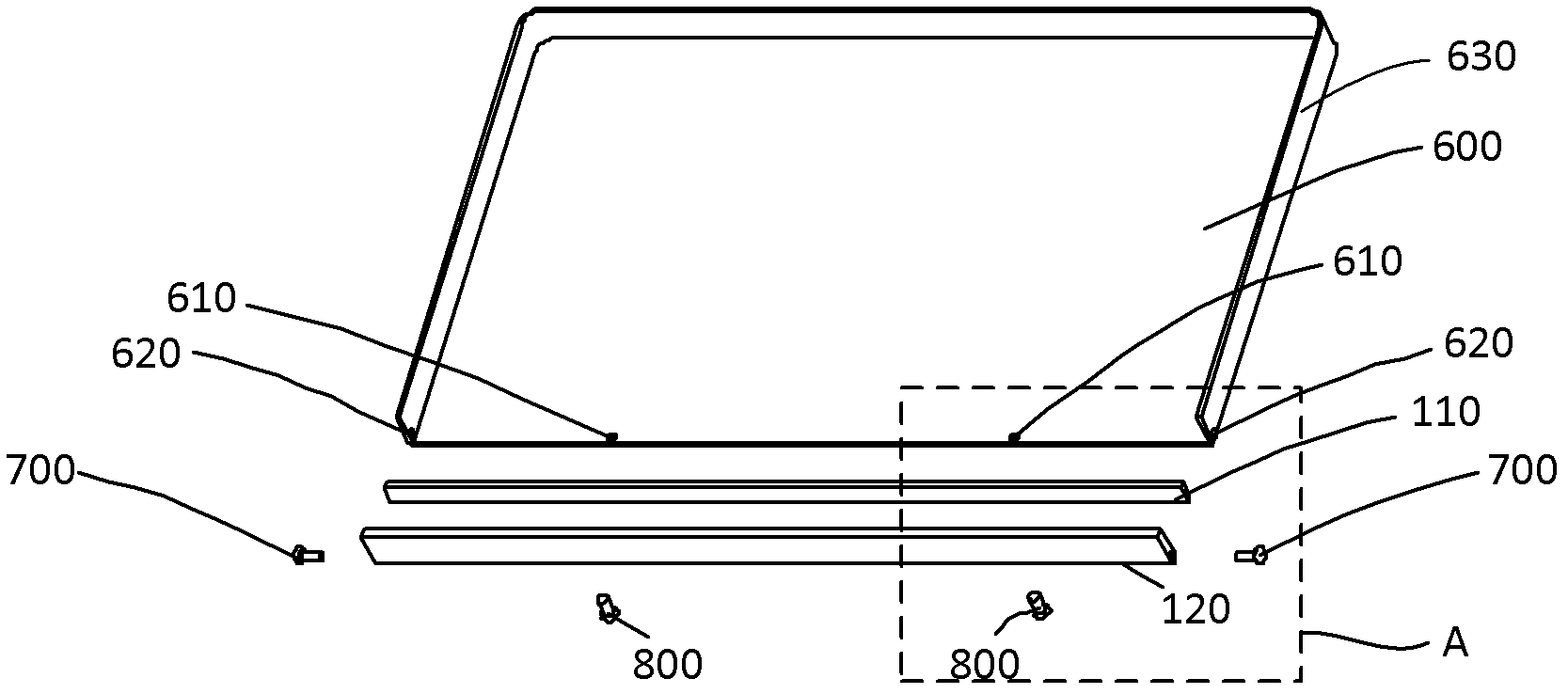

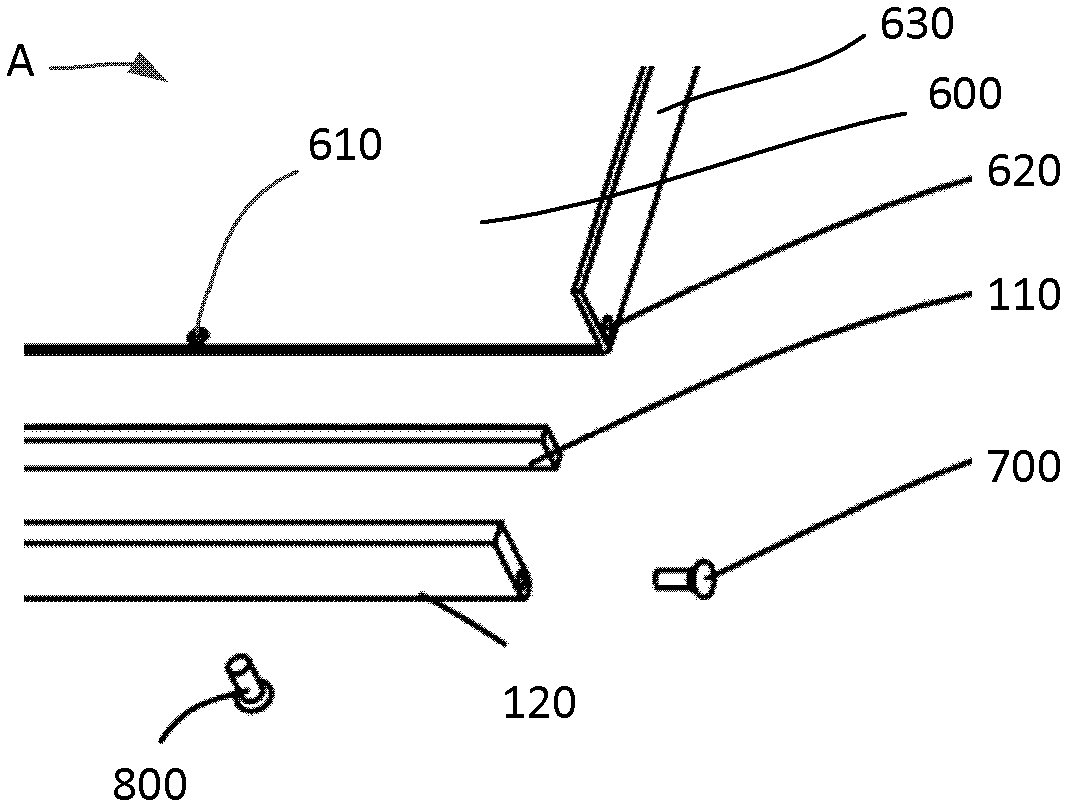

[0028] Such as figure 2 and image 3 Shown is a preferred embodiment of the present invention, as shown in the figure, the edge of the back frame 600 of the backlight module of the liquid crystal display device is respectively provided with three side walls 630, one edge of the back frame 600 is not provided with On the side wall, an opening is left here for installing the mounting bracket 120. The light bar 110 is fixed on the mounting bracket 120 by means of screws or adhesives, thereby providing a light source for the liquid crystal display device. The mounting bracket 120 is mounted to the back frame 600 by screws of the opening. Such as Figure 4 As shown, the bottom surface of the mounting bracket 120 is provided with a bottom blind hole 1220, and the bottom blind hole 1220 is a threaded hole, of course, it can also be a pin hole or other; correspondingly, as image 3 As shown, the edge of the bottom plate of the back frame 600 is provided with a bottom plate through...

Embodiment 2

[0032] The difference from Example 1 is that, if Figure 8 As shown, the fixed section of the end screw 900 used at both ends of the mounting bracket is the same as the diameter of the rotating shaft section, wherein the fixed section is provided with threads, of course, the rotating shaft section can also be provided with threads, so that common conventional Screws do not need to be specially customized, which saves production costs. However, if there is no thread on the rotating shaft section, the strength of the screw can be improved, and the friction between the screw and the blind hole on the end face of the mounting bracket can be avoided.

[0033] Of course, in the present invention, it is not necessary to provide threads on the fixing section, as long as the fixing section and the side wall through hole on the side wall of the back frame achieve the effect of locking and fixing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com