Novel boiler front feeding device of straw biomass CFB boiler

A feeding device and biomass technology, which is applied in the direction of combustion type, fuel burned in a molten state, lighting and heating equipment, etc., can solve the problems that affect the safe and stable operation of the boiler, low stacking density of biomass fuel, and poor fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

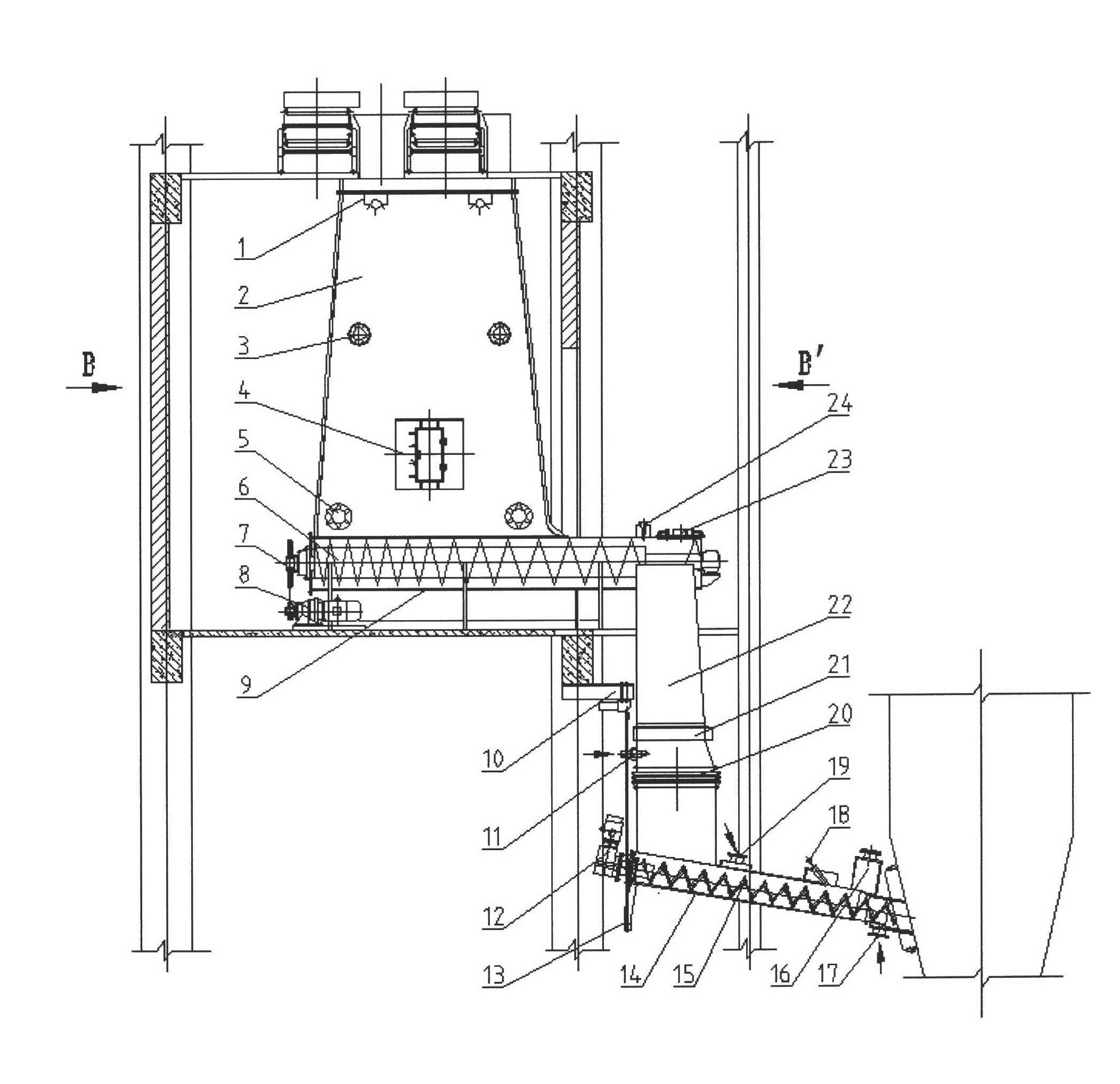

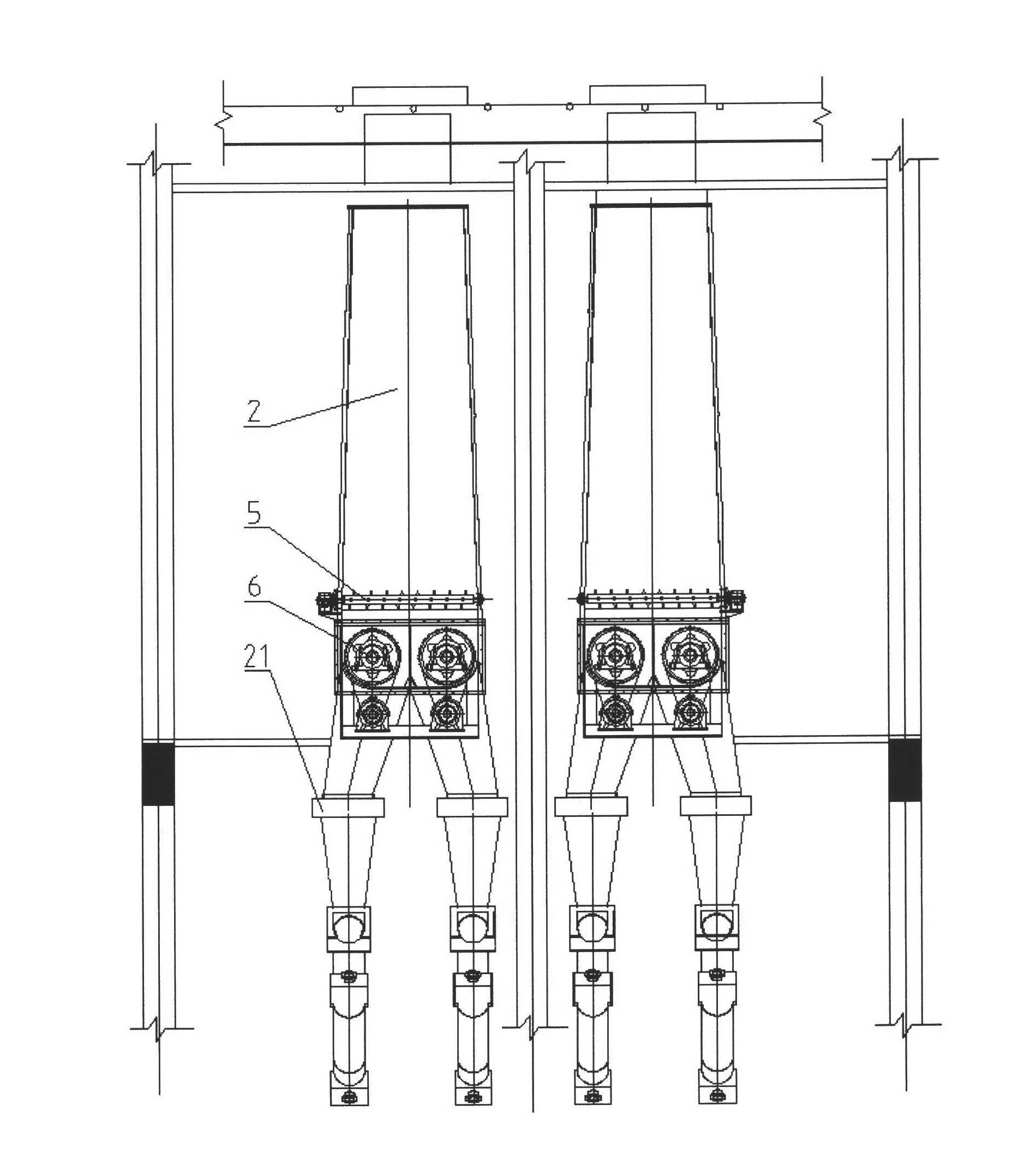

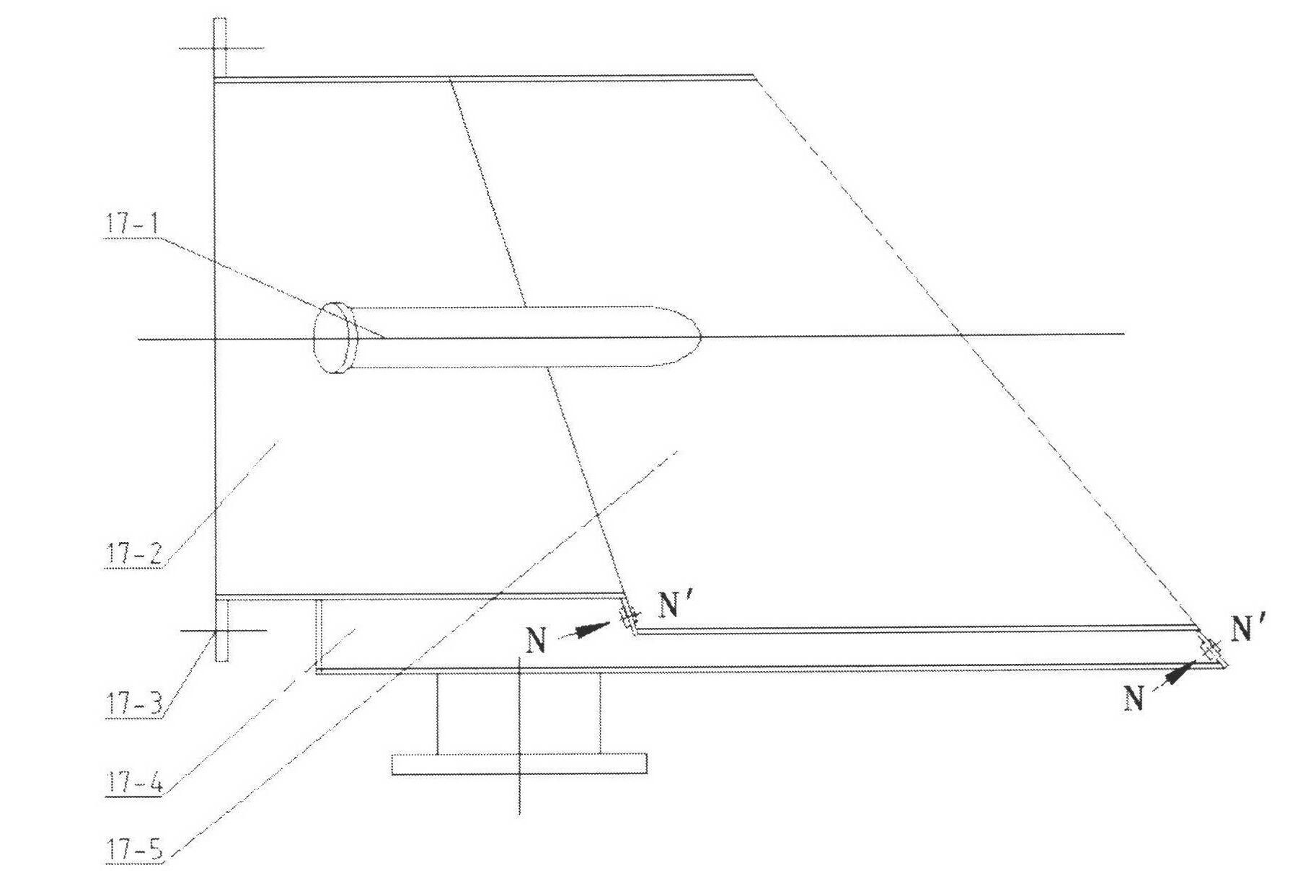

[0010] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0011] like figure 1 and figure 2 As shown, a new type of straw biomass CFB boiler furnace feed device, including the furnace feed bin assembly, a primary batching screw assembly, a drop pipe assembly, a secondary feeding screw assembly and a safety control assembly, the furnace front The silo assembly includes two silos 2, an infrared camera 1 is installed on the top of each silo 2, an explosion-proof release valve 3 is installed in the middle of both sides of the silo 2, and a manhole door 4 is arranged in the outer middle of the silo 2. The lower part of each silo 2 is provided with two activators 5, and the activators 5 are arranged near the front and rear walls of the silo 2 along the direction of the unloading screw axis, and are arranged at 500 mm above the lower part of the silo 2; The screw assembly includes two sets of double-row large-diameter shafted s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com