Filter bag breakage detector for bag type dust remover

A bag filter and damage detection technology, applied in the application of light to test fluid tightness, etc., can solve the problems of long time, time-consuming and laborious diagnosis of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

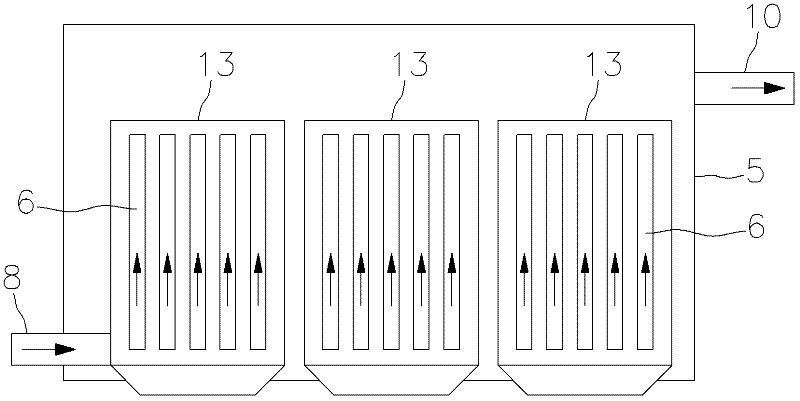

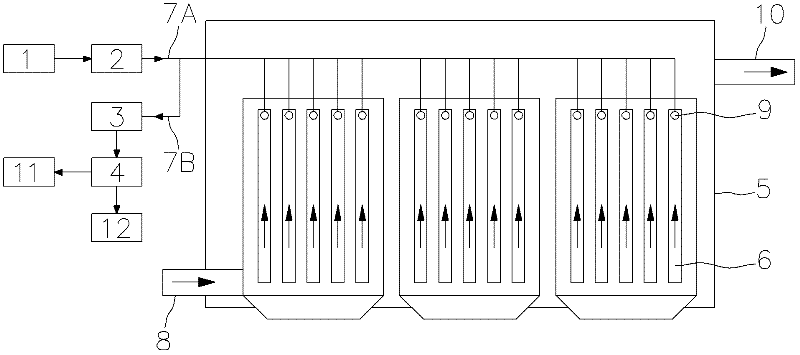

[0040] like figure 1 As shown, a filter bag breakage detection device for a bag filter, the detection device includes a light source 1, a light transmission mechanism and a light detection mechanism; the light transmission mechanism is used to transmit the light emitted by the light source 1 to the filter bag 6 at the exit of the filter bag; the optical detection mechanism is used to detect the light intensity at the exit of the filter bag 6, and the detected optical signal is sent to the photodetector 3, and the output of the photodetector 3 is provided with a data acquisition and processing module 4 .

[0041] preferred, such as figure 2 As shown, the light transmission mechanism includes a fiber optic beam splitter 2, a conductive fiber 7A and a high temperature resistant fiber optic probe 9; the fiber optic beam splitter 2 is connected to the light source 1 through an optical fiber, and divides the light emitted by the light source 1 into several bundles The light beam em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com