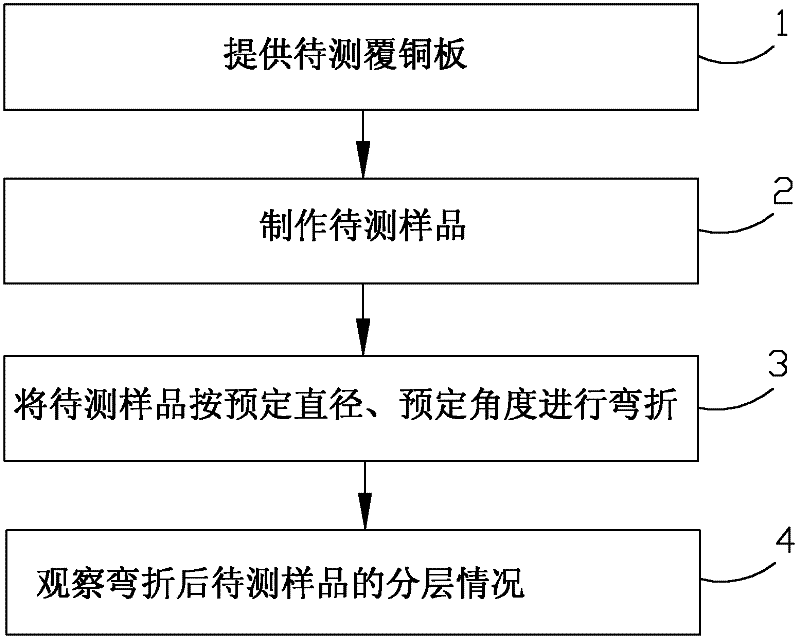

Assessment method of copper clad laminate mechanical properties

A technology of copper plate mechanics and copper clad laminates, applied in the field of evaluation, can solve the problem that there is no good evaluation method for the toughness of the insulating layer, there is no good evaluation method for the adhesion between the metal substrate and the adhesive layer, and it is not suitable for evaluating the metal substrate and adhesion. Problems such as the adhesion of the junction layer, to achieve the effect of improving the evaluation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

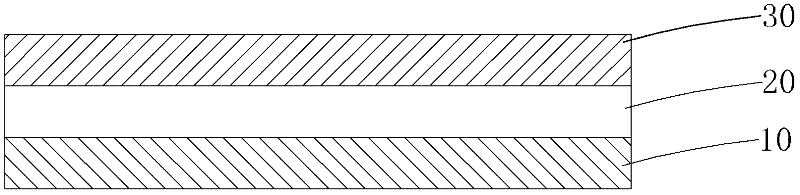

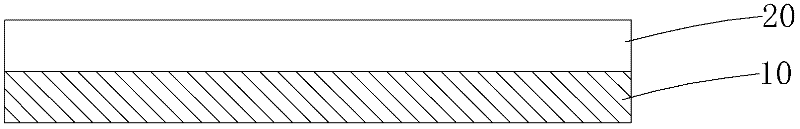

[0042] Provide the metal base copper clad laminate to be tested, refer to figure 2 As shown, it includes a metal substrate 10, a copper foil 30, and an adhesive layer 20 disposed between the metal substrate 10 and the copper foil 30. The copper foil 30 of the metal-based copper clad laminate is etched away, and the etched copper foil 30 is etched. The metal-based copper-clad laminate is cut into a sample to be tested with a width of 25 mm and a length of 250 mm. The structure of the sample to be tested is as follows: image 3 As shown, a metal substrate 10 and an adhesive layer 20 thereon are included.

[0043] like Figure 4 As shown, the sample to be tested is bent at a certain angle (30-180°) according to different diameters on the bending instrument 100 with its adhesive layer 20 facing outward, and the metal substrate 10 and the bonding of the sample to be tested are observed after bending. The delamination between the layers 20, comparative evaluation of the bonding f...

Embodiment 2

[0045] Provide the non-metal base copper clad laminate to be tested, refer to Figure 5 As shown, it includes copper foil 40 and an insulating layer 50 arranged between the copper foils 40. The non-metallic copper-clad laminate after etching the copper foil is cut into a sample to be tested with a width of 25 mm and a length of 250 mm. The structure of the sample to be tested is like Image 6 As shown, an insulating layer 50 is included, and the insulating layer 50 is an insulating layer of a non-metal-based copper clad laminate.

[0046] according to Figure 4 In the method shown, the sample to be tested is bent at a certain angle (30-180°) according to different diameters on the bending instrument 100, and the delamination of the insulating layer 50 is observed after bending to evaluate the insulation of the non-metallic copper-clad laminate. The toughness of layer 50.

[0047] In summary, the method for evaluating the mechanical properties of copper-clad laminates of the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com