Photoetching machine exposure method

An exposure method and lithography machine technology, applied in the field of lithography machine exposure, can solve the problems of equipment production capacity reduction, unsuitability for large-scale production, etc., and achieve the effect of large process window and uniform contrast of exposure graphics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The best mode for carrying out the present invention will be described below with reference to the drawings.

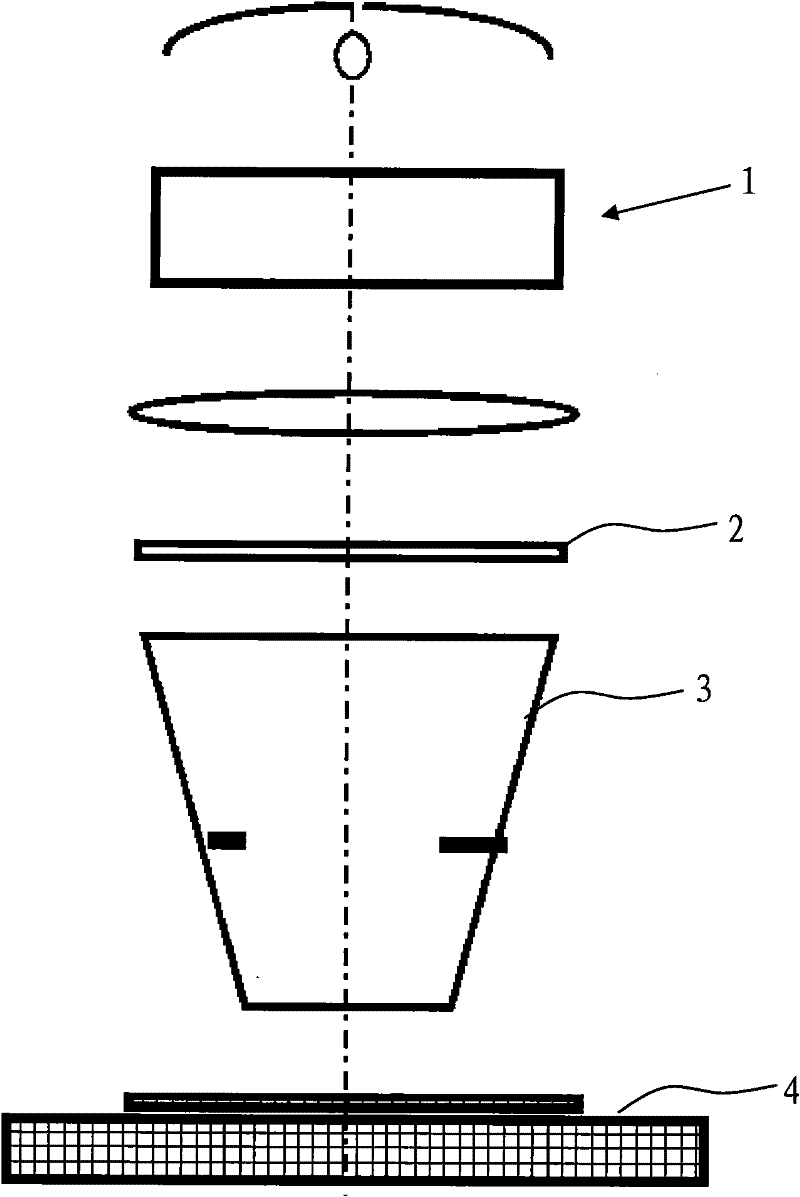

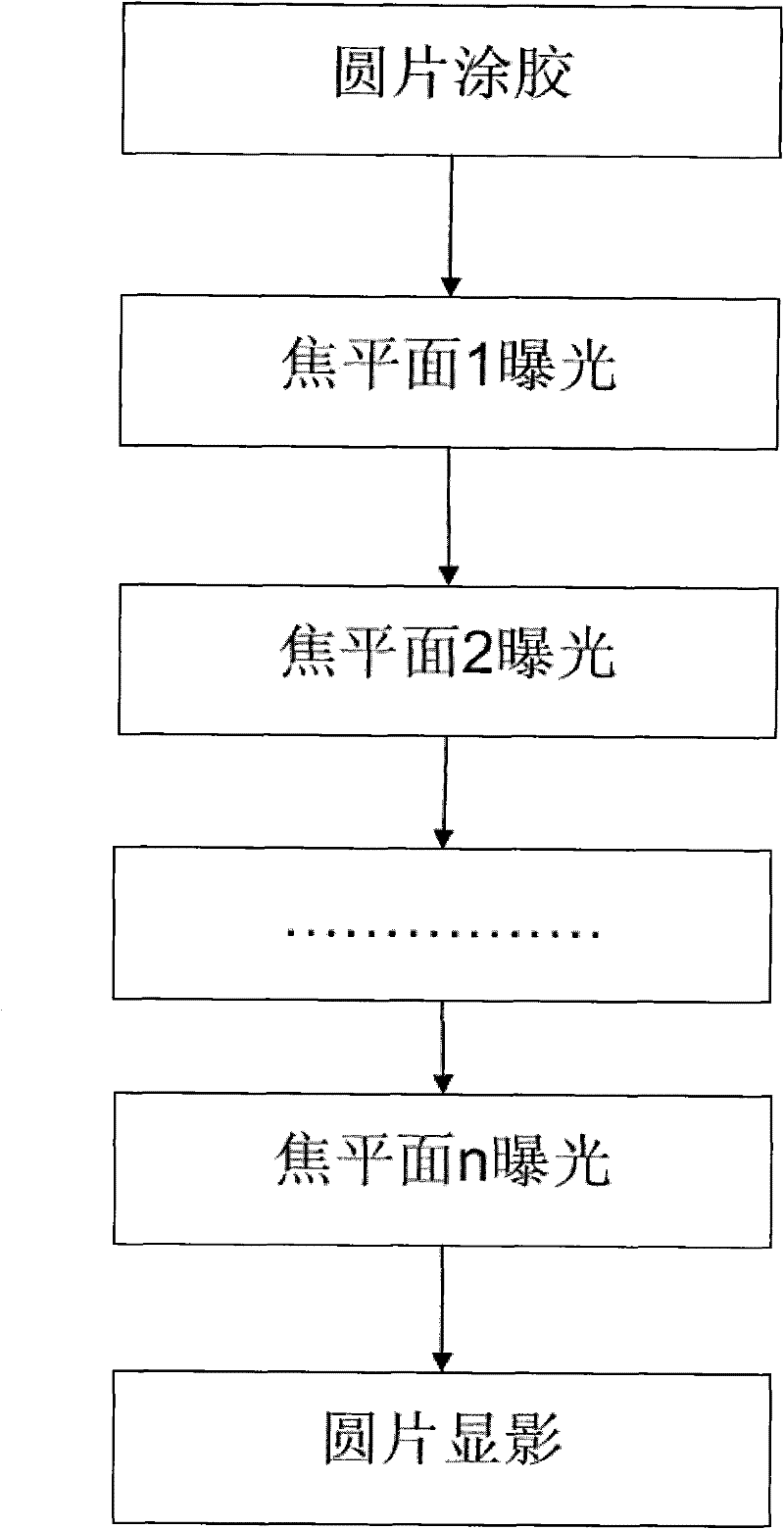

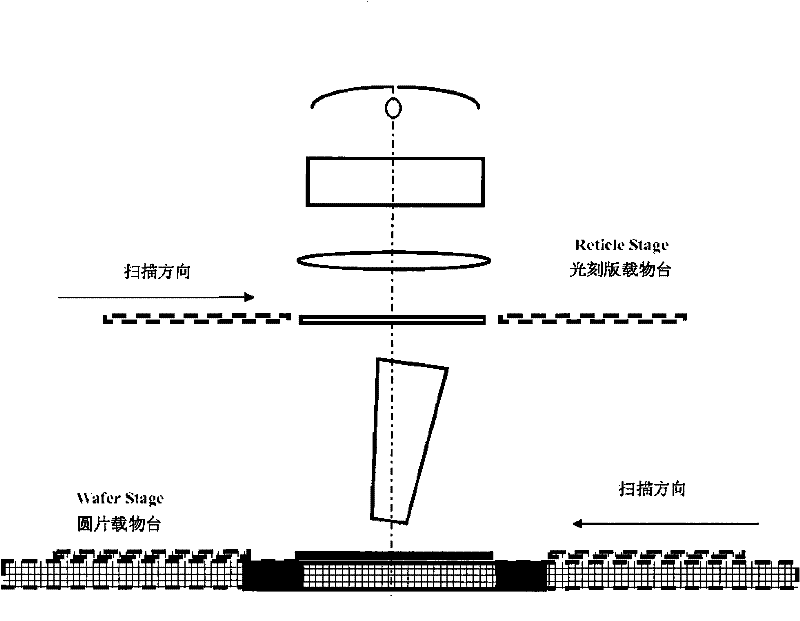

[0022] like image 3 As shown, the exposure method of the scanning stepper lithography machine disclosed in the present invention is applicable to the hole process and the bright field / dark field strip / space process in the photolithography process. During exposure, the lens is first adjusted and tilted at a certain angle along the scanning direction of the photolithography stage and the wafer stage, so that the focal length of the light projected onto the wafer through the slit-shaped lens is gradually changed; secondly, Exposure is performed by scanning the photoresist plate loading platform and the wafer loading platform. By adopting such a method, the effect of repeated exposure with multiple focal lengths can be obtained in one exposure, and a larger process window can be obtained. Of course, the wafer stage and the photolithography plate stage must alway...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com