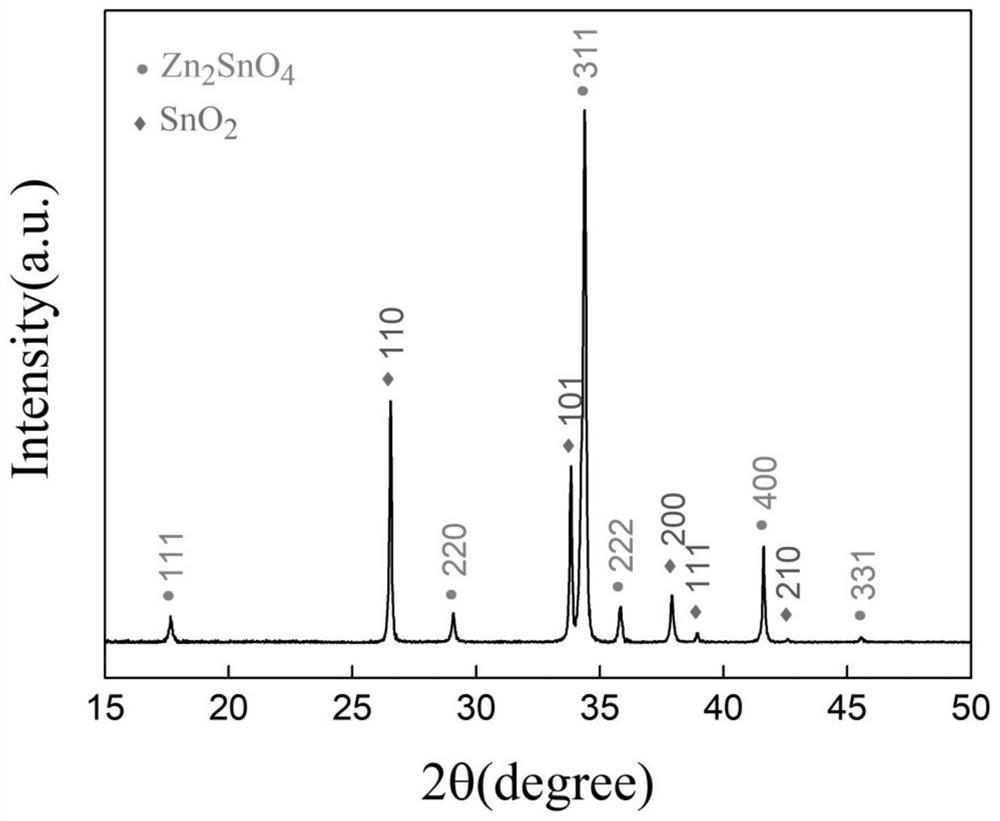

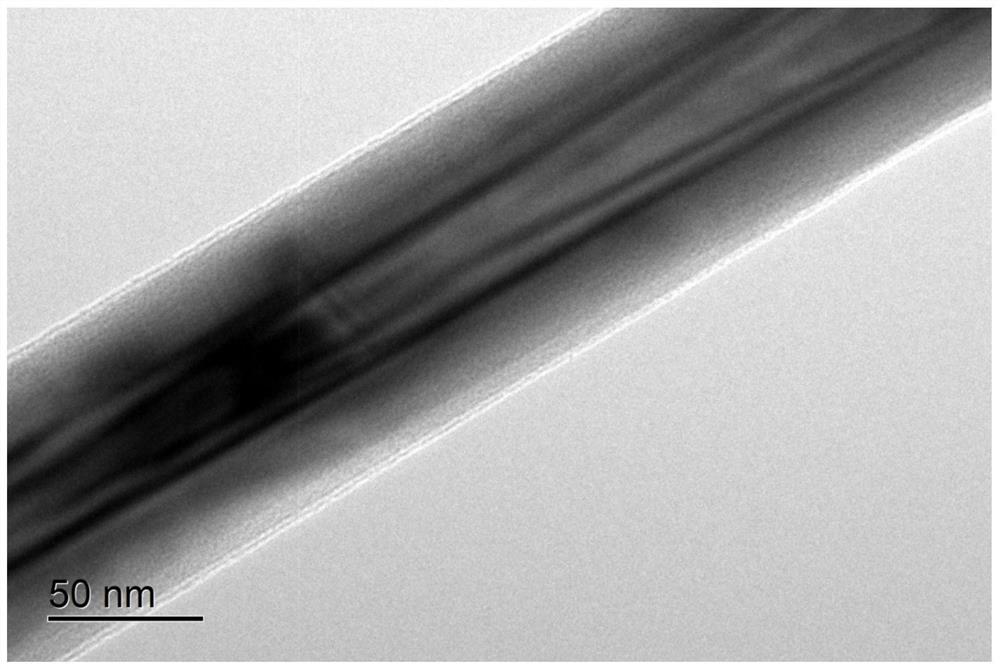

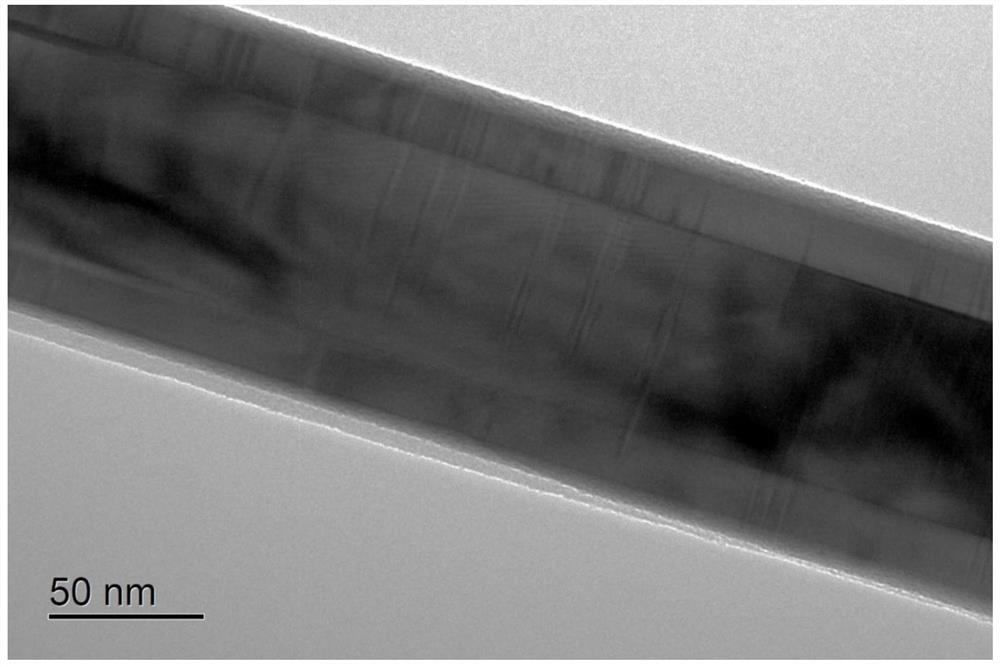

A kind of tin dioxide-zinc stannate core-shell nanowire and its preparation method

A technology of core-shell nanometers and tin dioxide, which is applied in chemical instruments and methods, nanotechnology, nanotechnology, etc., can solve the problems of unrealized core-shell nanowires, expensive equipment, high maintenance costs, etc., to achieve low price, Clear core-shell structure and good crystal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] A kind of SnO 2 -Zn 2 SnO 4 A method for preparing a core-shell nanowire, comprising the following steps:

[0030] Step 1: Incorporate the SnO 2 The powder and graphite powder are mixed at a molar ratio of 1:4 and ground evenly to obtain SnO 2 +C powder is placed in the high temperature zone of the chemical vapor deposition system; ZnO powder and graphite powder are mixed at a molar ratio of 1:1, and ground evenly to obtain ZnO+C powder, which is placed 30cm upstream of the center of the high temperature zone of the chemical vapor phase system.

[0031] Step 2: Select the C-face sapphire as the growth substrate, plate a 10nm-thick gold film on its surface by magnetron sputtering, and then place it in the low-temperature zone of the chemical vapor deposition system; feed in argon gas with a flow rate of 50sccm and oxygen gas with a flow rate of 5sscm, and keep The pressure is 1 Torr; the high temperature zone rises to 980°C, the low temperature zone rises to 918°C, a...

Embodiment

[0034] Follow the steps below to prepare SnO2 -Zn 2 SnO 4 Core-shell nanowires:

[0035] Step 1: Select the C-face sapphire as the growth substrate, and plate a 10nm thick gold film on its surface by magnetron sputtering technology, and then place it in the right half of the quartz tube with a length of 300mm and a diameter of 30mm;

[0036] High-purity SnO with a purity of 99.99% 2 The powder and graphite are mixed according to the molar ratio of 1:4, and ground evenly, and then the mixed powder is placed at the left end of the quartz tube;

[0037] Put the quartz tube with the substrate and the powder source into the reaction chamber of the chemical vapor deposition system, wherein the substrate is located in the center of the low temperature zone of the reaction chamber, and the powder source is located in the center of the high temperature zone of the reaction chamber;

[0038] Mix high-purity ZnO powder with a purity of 99.99% and graphite at a molar ratio of 1:1, grin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com