Mixed material for display screen substrate of intelligent equipment

A technology of mixing materials and smart devices, applied in the field of smart device display materials, to achieve the effects of super weather resistance, uniform light contrast, and not easy to damage the eyes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

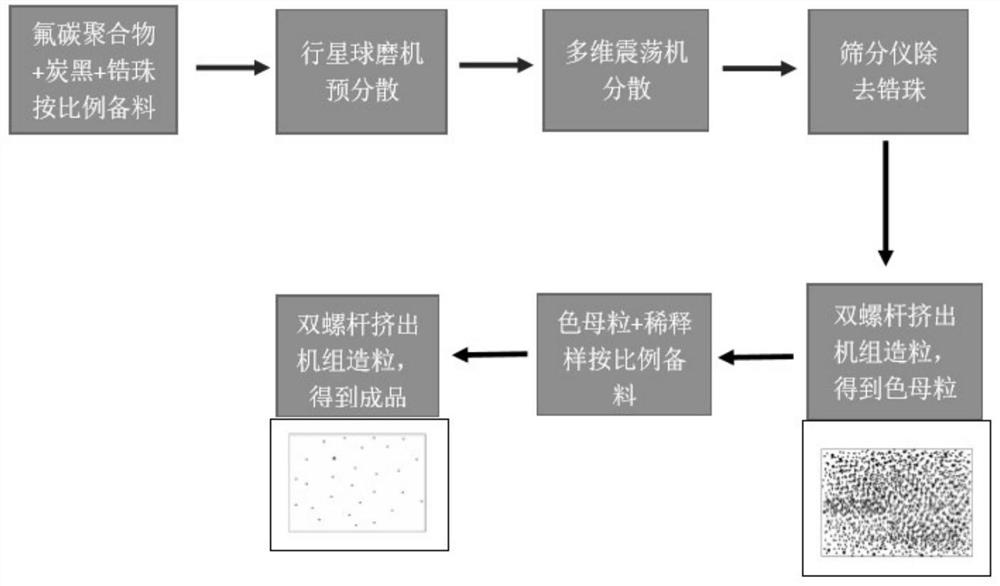

[0042] Prepare the mixed material for the smart device display substrate according to the following preparation method:

[0043] S1. Material configuration

[0044] Add 495g of fluorocarbon polymer, 5g of carbon black particles and 250g of zirconia beads in sequence in the zirconia tank, seal and set aside;

[0045] S2. Pre-dispersion of materials

[0046] Put the zirconia tank prepared in step S1 into a planetary ball mill for pre-dispersion. The autopropagation speed of the ball mill is 120±6 revolutions / minute, the revolution speed is 12±1 revolutions / minute, and the mixture is discharged after 1±0.1h to obtain mixture A;

[0047] S3. Dispersion of materials

[0048] Put the mixture A obtained in step S2 into multiple 480mL ellipsoidal glass bottles, the amount of mixture A added to each glass bottle does not exceed 1 / 2 of the volume of the glass bottle, seal it and place it in a multidimensional shaker for further dispersion , vibrated and mixed for 3 hours, and discha...

Embodiment 2

[0058] Prepare the mixed material for the smart device display substrate according to the following preparation method:

[0059] S1. Material configuration

[0060] Add 495g of fluorocarbon polymer, 5g of carbon black particles and 250g of zirconia beads in sequence in the zirconia tank, seal and set aside;

[0061] S2. Pre-dispersion of materials

[0062] Put the zirconia tank prepared in step S1 into a planetary ball mill for pre-dispersion. The autopropagation speed of the ball mill is 120±6 revolutions / minute, the revolution speed is 12±1 revolutions / minute, and the mixture is discharged after 1±0.1h to obtain mixture A;

[0063] S3. Dispersion of materials

[0064] Put the mixture A obtained in step S2 into multiple 480mL ellipsoidal glass bottles, the amount of mixture A added to each glass bottle does not exceed 1 / 2 of the volume of the glass bottle, seal it and place it in a multidimensional shaker for further dispersion , vibrated and mixed for 3 hours, and discha...

Embodiment 3

[0074] Prepare the mixed material for the smart device display substrate according to the following preparation method:

[0075] S1. Material configuration

[0076] Add 495g of fluorocarbon polymer, 5g of carbon black particles and 250g of zirconia beads in sequence in the zirconia tank, seal and set aside;

[0077] S2. Pre-dispersion of materials

[0078] Put the zirconia tank prepared in step S1 into a planetary ball mill for pre-dispersion. The autopropagation speed of the ball mill is 120±6 revolutions / minute, the revolution speed is 12±1 revolutions / minute, and the mixture is discharged after 1±0.1h to obtain mixture A;

[0079] S3. Dispersion of materials

[0080] Put the mixture A obtained in step S2 into multiple 480mL ellipsoidal glass bottles, the amount of mixture A added to each glass bottle does not exceed 1 / 2 of the volume of the glass bottle, seal it and place it in a multidimensional shaker for further dispersion , vibrated and mixed for 3 hours, and discha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com