Method for manufacturing floating body effect storage unit

A memory cell, floating body effect technology, applied in the manufacture of semiconductor/solid state devices, electrical components, circuits, etc., can solve the problems of hole accumulation, the inability to release the substrate current, etc., to improve the writing speed, enhance the impact ionization rate, The effect of increasing the substrate current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

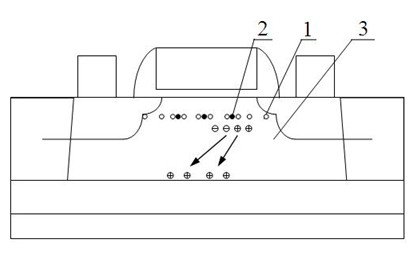

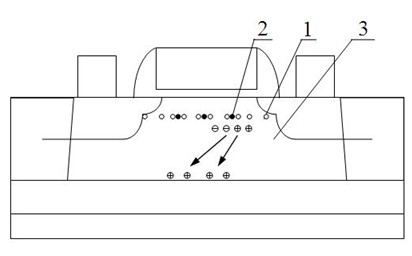

[0018] The preparation method of the floating body effect memory unit provided by the present invention increases the method of reverse injection in the threshold voltage element injection process of the floating body effect memory unit preparation process, and enhances the carrier and the impurity scattering center in the device channel 3 The impact ionization rate between them increases the substrate current of the floating body effect memory cell and improves the writing speed of the floating body effect memory cell.

[0019] In addition, in the embodiment of the present invention, the element injected forward is the third group element, and the element injected backward is the fifth group element; or the element injected forward is the fifth group element, and the element injected backward is Group III elements. Among them, the Group III element is preferably boron, and the Group V element is preferably phosphorus.

[0020] In summary, the present invention has the advant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com