MWT (Metal Wrap-Through) solar cell assembly and manufacturing method thereof

A technology for a solar cell module and a manufacturing method, applied in the field of solar cells, can solve the problems of short circuit, high cost of component line equipment, and no verification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

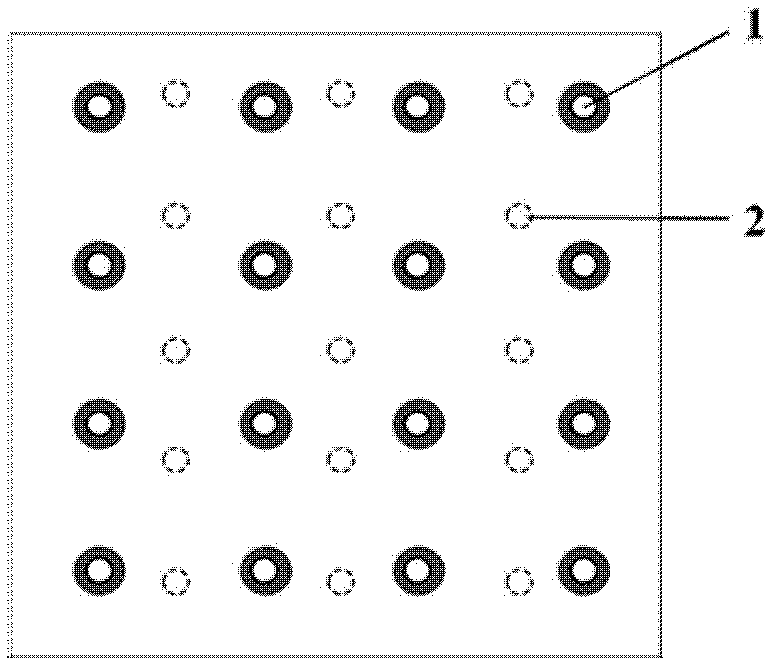

[0096] As shown in Figure 2, a method for manufacturing a MWT solar cell module provided in this embodiment includes the following steps:

[0097] (1) Preparation of MWT solar cells

[0098] The backside electrode pattern of the cell has been rationally designed so that the patterns of the emitter electrode and the base electrode are suitable for ribbon welding, such as Figure 2a As shown, the center line of the emitter electrode and the base electrode of the battery is on a straight line, wherein the emitter electrode and the base electrode are aligned on the straight line, the shape of the emitter electrode and the base electrode is a continuous strip, and the pattern of the back electrode Reasonable design specifically includes:

[0099] a. The number of electrodes of the same polarity (that is, the number of emitter electrodes or base electrode busbar lines) ranges from 2 to 10;

[0100] b The shape of the emitter electrode or the base electrode can be continuous or dis...

Embodiment 2

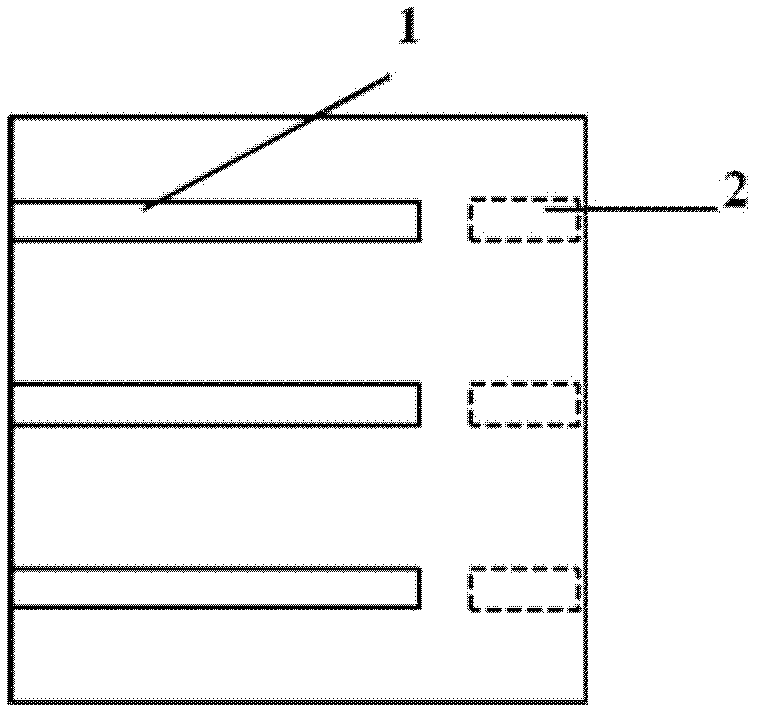

[0113] A method for manufacturing a MWT solar cell assembly provided in this embodiment includes the following steps:

[0114] (1) Preparation of MWT solar cells

[0115] The backside electrode pattern of the cell has been rationally designed so that the patterns of the emitter electrode and the base electrode are suitable for ribbon welding, such as Figure 3a As shown, the center lines of the emitter and base electrodes of the battery are not in a straight line, the emitter electrodes and the base electrodes are parallel to each other, the shape of the emitter electrode and the base electrode is a continuous strip, and the rational design of the back electrode pattern is specific include:

[0116] a. The number of electrodes of the same polarity (that is, the number of emitter electrodes or base electrode busbar lines) ranges from 2 to 10;

[0117] b The shape of the emitter electrode or the base electrode can be continuous or discontinuous, and the shape of the emitter el...

Embodiment 3

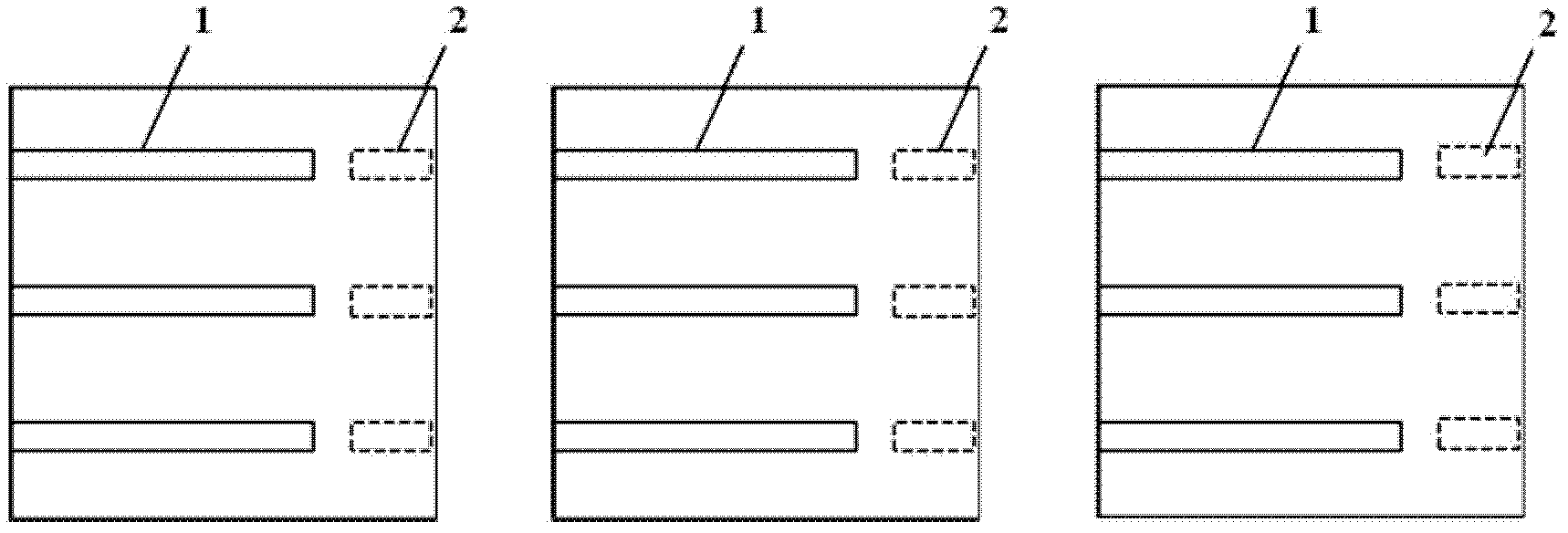

[0130] A method for manufacturing a MWT solar cell assembly provided in this embodiment includes the following steps:

[0131] (1) Preparation of MWT solar cells

[0132] The backside electrode pattern of the cell has been rationally designed so that the patterns of the emitter electrode and the base electrode are suitable for ribbon welding, such as Figure 4a As shown, the center lines of the emitter electrode and the base electrode of the battery are not on a straight line, the emitter electrode and the base electrode are parallel to each other, and the shape of the emitter electrode is a disconnected strip. The emitter electrode in this embodiment The shape is a two-stage strip body, and the reasonable design of the back electrode pattern specifically includes:

[0133] a. The number of electrodes of the same polarity (that is, the number of emitter electrodes or base electrode busbar lines) ranges from 2 to 10;

[0134] b The shape of the emitter electrode or the base e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com