Constant current control device for switching power supply

A constant current control, switching power supply technology, applied in control/regulation systems, output power conversion devices, electrical components, etc., can solve the problem of primary peak current control error, can not guarantee that the Lp of the transformer must be equal, mass production Errors and other problems, to achieve the effect of improving system reliability, simplifying design and composition, and reducing system cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

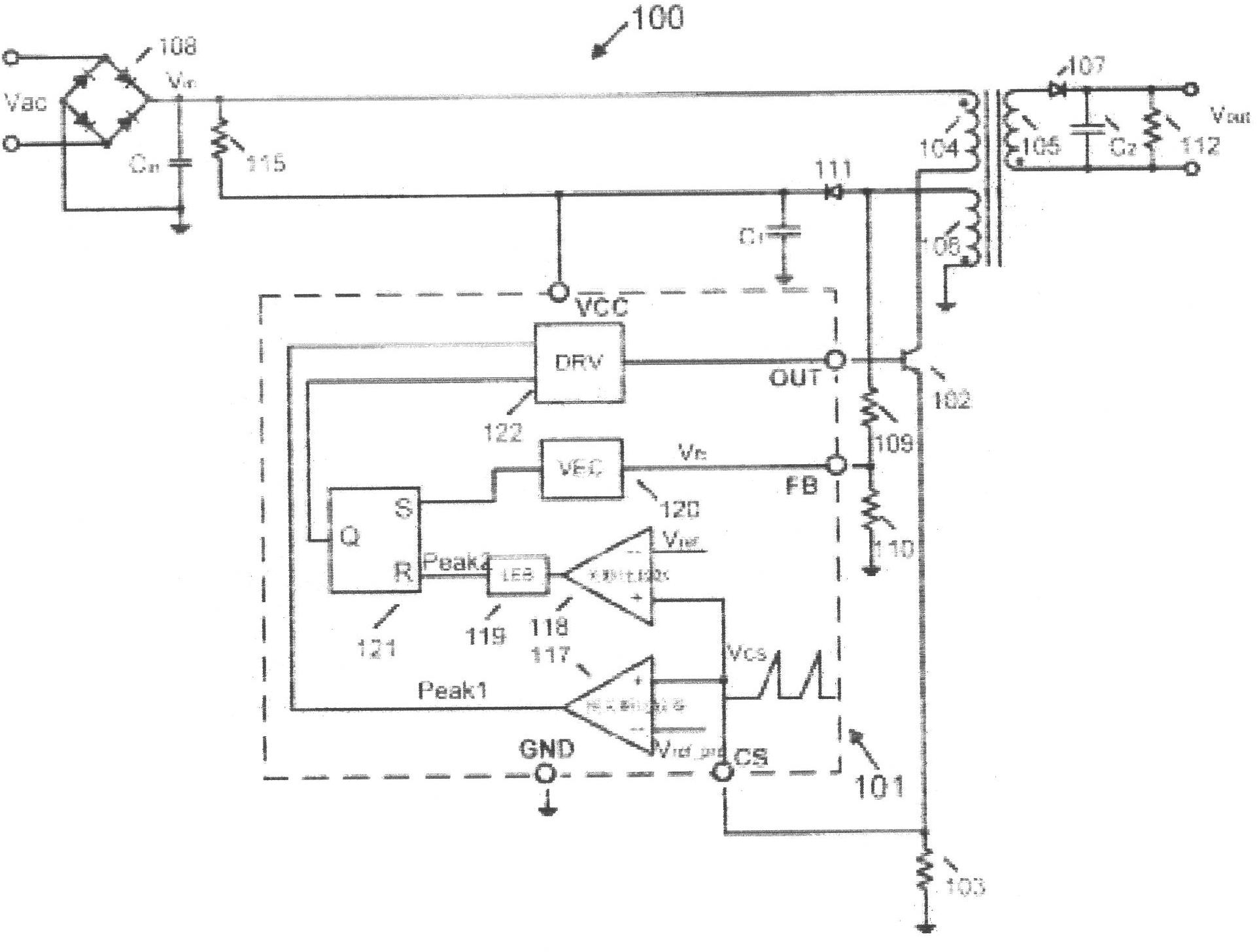

[0025] Examples, see Figure 5 As shown in the switching power supply constant current control device, the slope detection module 317 detects the slope of the voltage on the current sampling resistor 309 of the power supply circuit and converts it into a corresponding slope voltage, and the voltage compensation module 316 converts the slope voltage and Vref of the voltage compensation module 316 The voltage of the pin is added to obtain the Vref pin voltage of the voltage compensation module 316, and the Vref pin voltage of the voltage compensation module 316 is used as the threshold voltage of the shut-off comparator 315, and the other end of the shut-off comparator 315 is connected to the sampling resistor 309 The voltage Vcs is connected, the threshold voltage is compared with the voltage Vcs on the sampling resistor 309 , and a control signal is output to the reset signal of the R-S flip-flop 313 to trigger the driving circuit 312 to work, that is, to turn off the switch tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com