Production method of stepped groove circuit board with through hole, soldermask and circuit graphics at groove bottom

A technology of circuit graphics and manufacturing methods, which is applied in the direction of multilayer circuit manufacturing, secondary processing of printed circuits, and electrical connection formation of printed components, etc. It can solve the problems of bubbling, failure to manufacture, and cracking of laminated prepregs to prevent peeling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

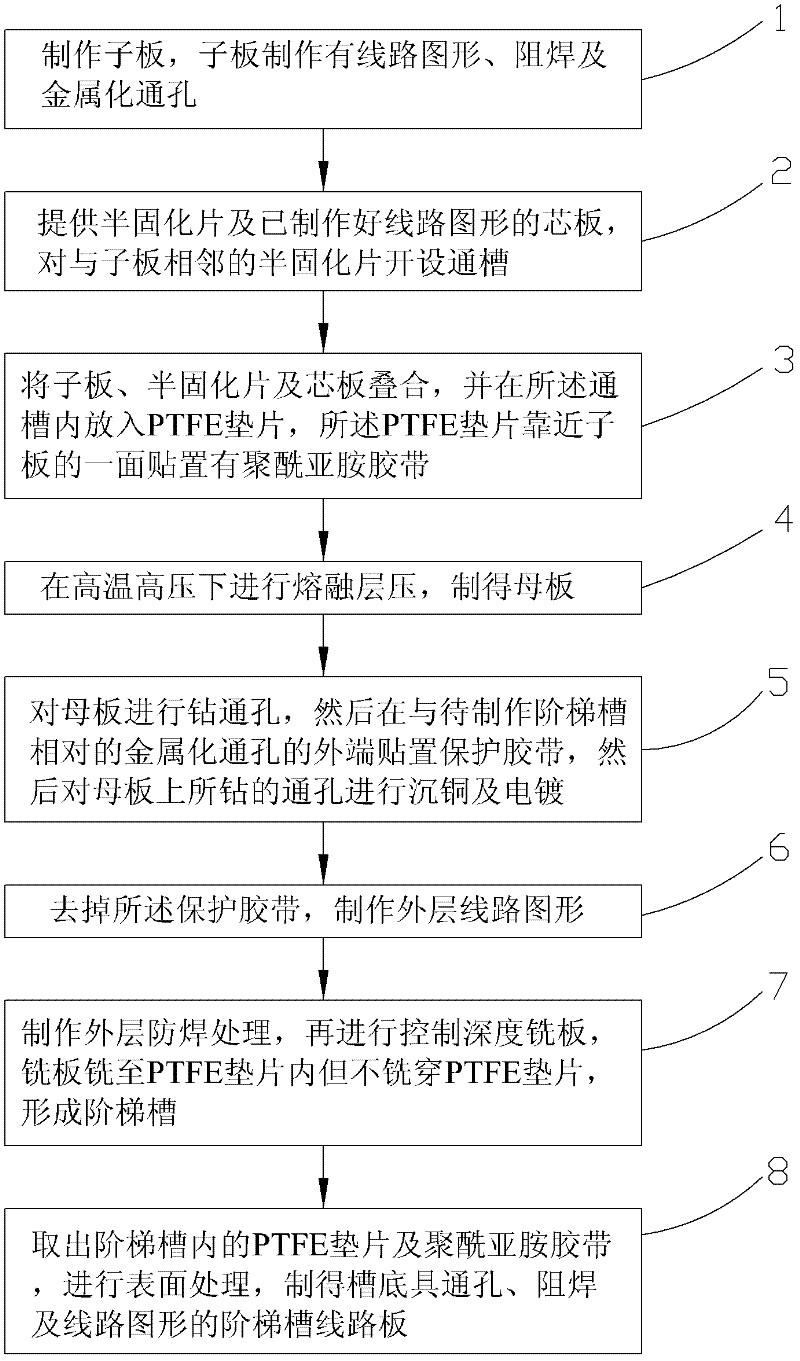

[0021] like Figure 1 to Figure 8 Shown, the manufacturing method of the stepped groove circuit board of groove bottom tool through hole, solder resist and circuit pattern of the present invention, comprises the following steps:

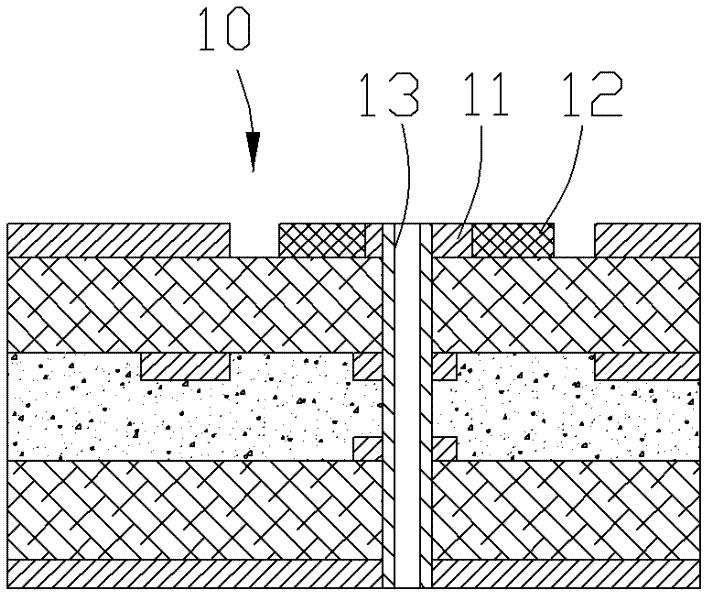

[0022] Step 1: make the sub-board 10, the sub-board 10 is facing the step groove 80 to be made ( Figure 8 As shown), one side of the circuit pattern 11 and solder resist 12 are made, and the position of the prepared sub-board and the step groove 80 to be made is made with a metallized through hole 13, such as figure 2 Shown is a schematic structural view of the fabricated sub-board 10;

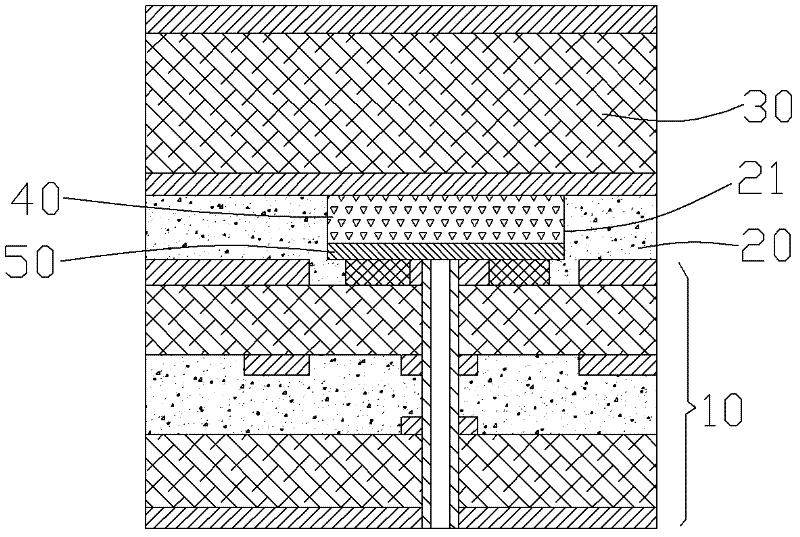

[0023] Step 2: Provide a prepreg 20 and a core board 30 (core boards of other layers except the sub-board 10 ) on which the circuit pattern has been made, and open a through groove 21 on the prepreg 20 adjacent to the sub-board 10 ;

[0024] Step 3: laminate the sub-board 10, the prepreg 20 and the core board 30 according to a predetermined stacking sequence, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com