Surgical anti-adhesion flushing liquid

An anti-adhesion and flushing solution technology, which is applied in the field of medicine, can solve the problems of short retention time, affecting the wide application of sodium hyaluronate gel, and small amount of clinical use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

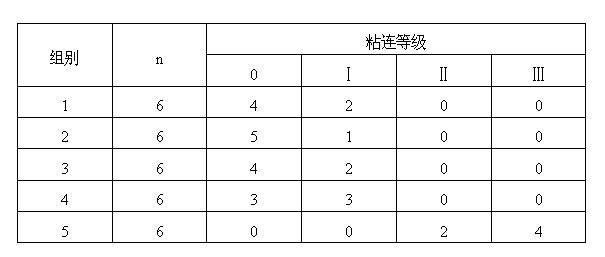

Image

Examples

Embodiment 1

[0032] Embodiment 1: the preparation of sodium hyaluronate anti-adhesion flushing solution

[0033] Preparation of 0.1% sodium hyaluronate anti-adhesion flushing solution

[0034] 1. In a 100-grade purification environment, weigh 10 grams of sodium hyaluronate and 85 grams of sodium chloride in 3000 ml of water for injection, shake 1-2 times a day, dissolve for 7 days, and make concentrated sodium hyaluronate solution A;

[0035] 2. In a 100-grade purification environment, add water for injection filtered through a 0.22-micron filter to the A solution until the total amount of the medicinal solution is 10 liters, stir to dissolve evenly, and make a B solution;

[0036] 3. In a 100-grade purification environment, filter the B solution with a 0.22 micron filter;

[0037] 4. Pack the above-mentioned filtered medicinal liquid into polyvinyl chloride plastic bags, 2000ml / bag, and seal with a transfusion plug;

[0038] 5. In a 100-level purification environment, seal t...

Embodiment 2

[0054] Embodiment 2: Preparation of sodium hyaluronate-glycine anti-adhesion flushing solution

[0055] Preparation of 0.03% Sodium Hyaluronate-3.0% Glycine Anti-adhesion Washing Solution

[0056] 1. In a 100-grade purification environment, weigh 3.0 grams of sodium hyaluronate and 300 grams of glycine and dissolve them in 3000 ml of water for injection, shake 1-2 times a day, dissolve for 7 days, and make concentrated solution A;

[0057] 2. In a 100-grade purification environment, add water for injection filtered through a 0.22-micron filter to the solution A to a total of 10 liters, and fill with nitrogen (pressure 0.2 MPa ~ 0.25 MPa). Stir to dissolve for 30 minutes to make the solution uniform.

[0058] 3. Glacial acetic acid adjusts the pH value to 5.5-6.0;

[0059] 4. The liquid medicine is filtered through a filter element of 0.22 microns (polypropylene);

[0060] 5. Pack the above-mentioned filtered medicinal liquid into polyvinyl chloride plastic bags, 200...

Embodiment 3

[0079] Embodiment 3: Preparation of sodium hyaluronate-glucose anti-adhesion flushing solution

[0080] Preparation of 0.03% sodium hyaluronate-5.0% glucose anti-adhesion flushing solution

[0081] 1. In a class 100 purification environment, weigh 3.0 grams and 500 grams of sodium hyaluronate, dissolve them in 3000 ml of water for injection, shake 1-2 times a day, dissolve for 7 days, and make a concentrated solution A;

[0082] 2. In a 100-grade purification environment, add water for injection filtered through a 0.22-micron filter to 10 liters of solution A, and heat (at a temperature of 70°C to 80°C). Stir and dissolve for 30 minutes, and cool to 25°C to 30°C after fully dissolving.

[0083] 3. The liquid medicine is filtered through a folded filter element of 0.22 microns (polypropylene);

[0084] 4. Pack the above-mentioned filtered medicinal liquid into polyvinyl chloride plastic bags, 2000ml / bag, and seal with a transfusion plug;

[0085] 5. In a 100-level pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com