Air bag type integrated anesthesia mask and its processing method

An anesthesia mask and processing method technology, applied in the field of medical devices, can solve problems affecting product quality, easy to generate air bubbles, and difficult to form integrally, and achieve the effects of saving materials, ensuring harmlessness, and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

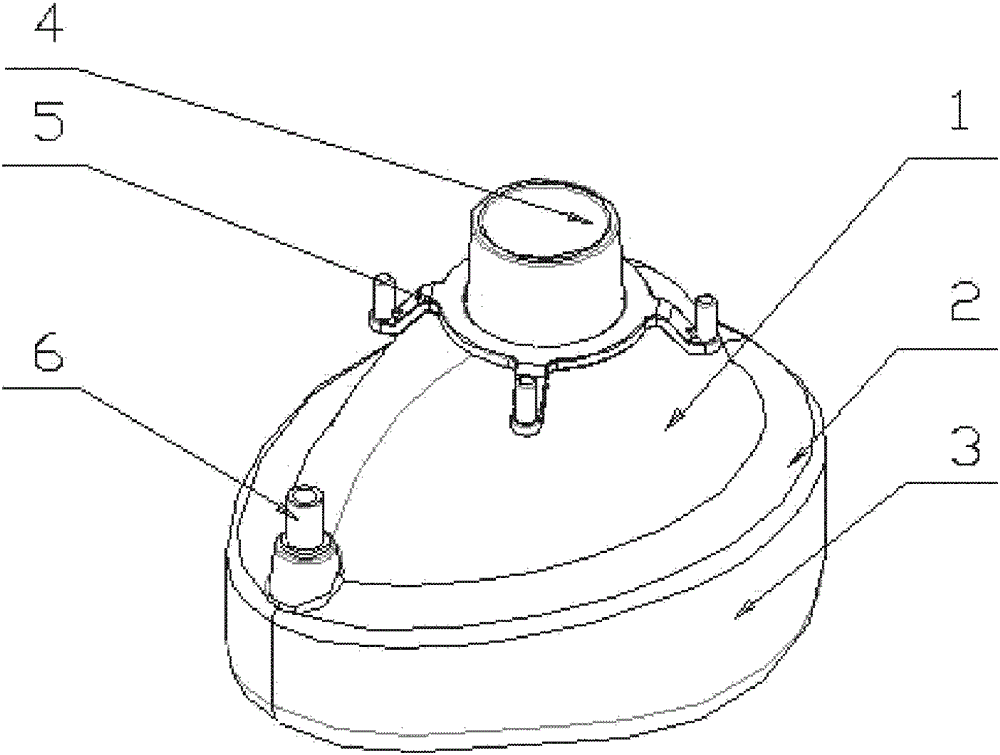

[0031] A kind of airbag type integrated anesthesia mask provided by the present embodiment is as follows: figure 1 As shown, an airbag-type integrated anesthesia mask includes a mask body 1, an anesthesia nozzle 4 integrally formed with it on the top of the mask body 1, an annular pad 2 integrally formed with it along the bottom periphery of the mask body 1, and an annular pad 2 There is an annular airbag 3 at the bottom, which is used to fit the patient's mouth and nose, wherein the annular airbag 3 is glued by sloshing glue, and is integrally formed with the cover body 1, that is, the ring pad 2 is connected to the bottom of the cover body 1 Formed integrally, the annular airbag 3 is also integrally formed with the annular pad 2 , and the anesthesia nozzle 4 is also integrally formed with the cover body 1 .

[0032] In order to facilitate the inflation and deflation of the annular airbag 3, a check valve 6 connected with the airbag is also provided on the annular pad 2. When...

Embodiment 2

[0034] Refer to Example 1 for the structure of the airbag-type integrated anesthesia mask.

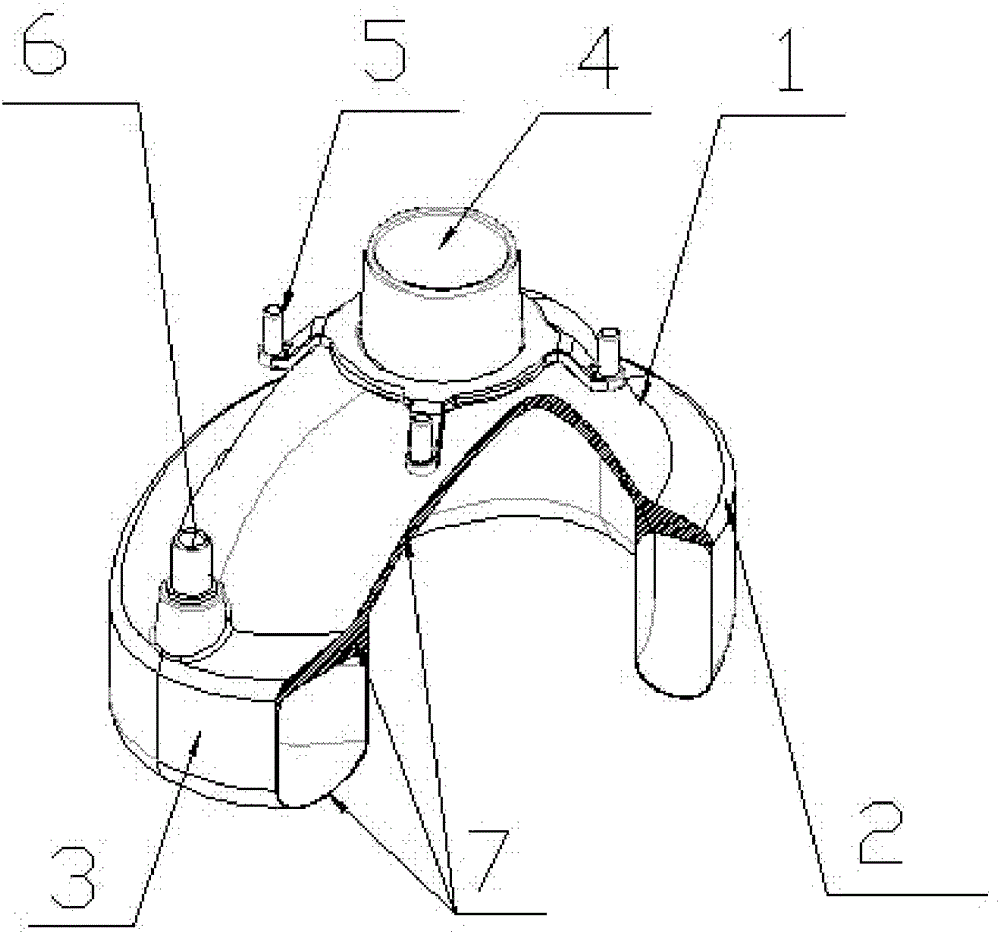

[0035] The processing technology of the above-mentioned airbag type integrated anesthesia mask provided by the present embodiment is as follows: figure 2 As shown, the above-mentioned airbag-type integrated anesthesia mask, its mask body 1, annular cushion 2, annular airbag 3, and anesthesia nozzle 4 are all processed and formed in one piece at one time, and the uneven integration of the anesthesia mask is mainly achieved in the following ways molding 7;

[0036] (1) Glue the mold of the mask body and the anesthesia nozzle by dipping in layers, then adjust the temperature to 200°C to heat the mold of the mask body and the anesthesia nozzle for 5 minutes, soak the glue for 5 seconds, and set the shape at 180°C for 1 minutes, and repeat this process 2 times;

[0037] (2) Apply glue to the mold of the airbag part by sloshing glue at room temperature, then level it at 20°C for 5 minutes...

Embodiment 3

[0044] Refer to Example 1 for the structure of the airbag-type integrated anesthesia mask.

[0045] The processing technology of the above-mentioned airbag type integrated anesthesia mask provided by the present embodiment is as follows: figure 2 As shown, the above-mentioned airbag-type integrated anesthesia mask, its mask body 1, annular cushion 2, annular airbag 3, and anesthesia nozzle 4 are all processed and formed in one piece at one time, and the uneven integration of the anesthesia mask is mainly achieved in the following ways molding 7;

[0046] (1) Glue the mold of the mask body and the anesthesia nozzle by dipping in layers, then adjust the temperature to 220°C to heat the mold of the mask body and the anesthesia nozzle for 4 minutes, soak the glue for 10 seconds, and set the shape at 180°C for 1 minutes, and repeat this process 4 times;

[0047] (2) Apply glue to the mold of the airbag part by sloshing glue at room temperature, then level it at 70°C for 2 minutes,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com