Welding torch, welding tip, and welding robot

A welding tip and welding torch technology, applied in welding equipment, electrode characteristics, arc welding equipment, etc., can solve the problems of screw crushing, difficulty in increasing or decreasing force of welding tip for disassembly and assembly, and insufficient simplification of disassembly and assembly operations. , to achieve the effect of easy disassembly and assembly and elimination of welding tip sticking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0115] Next, the results of welding using a welding torch (Example) having a specified configuration according to the present invention are compared with the results of welding using a conventional welding torch (Comparative Example) not having a specified configuration according to the present invention. The welding torch of the present invention.

[0116]

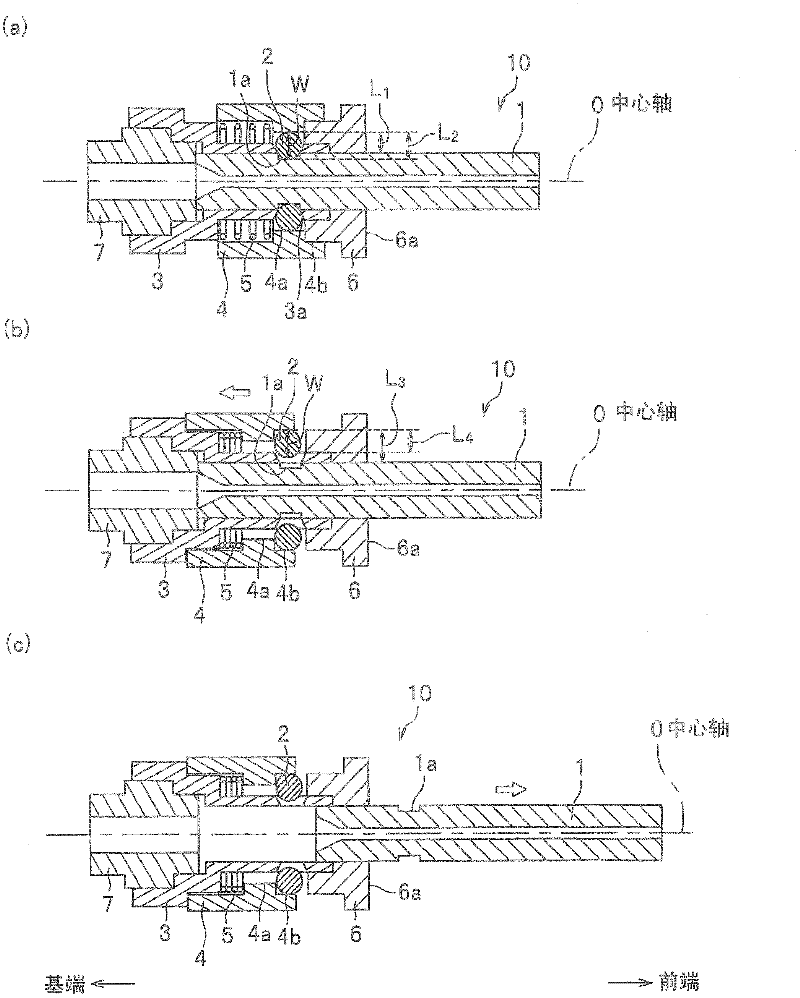

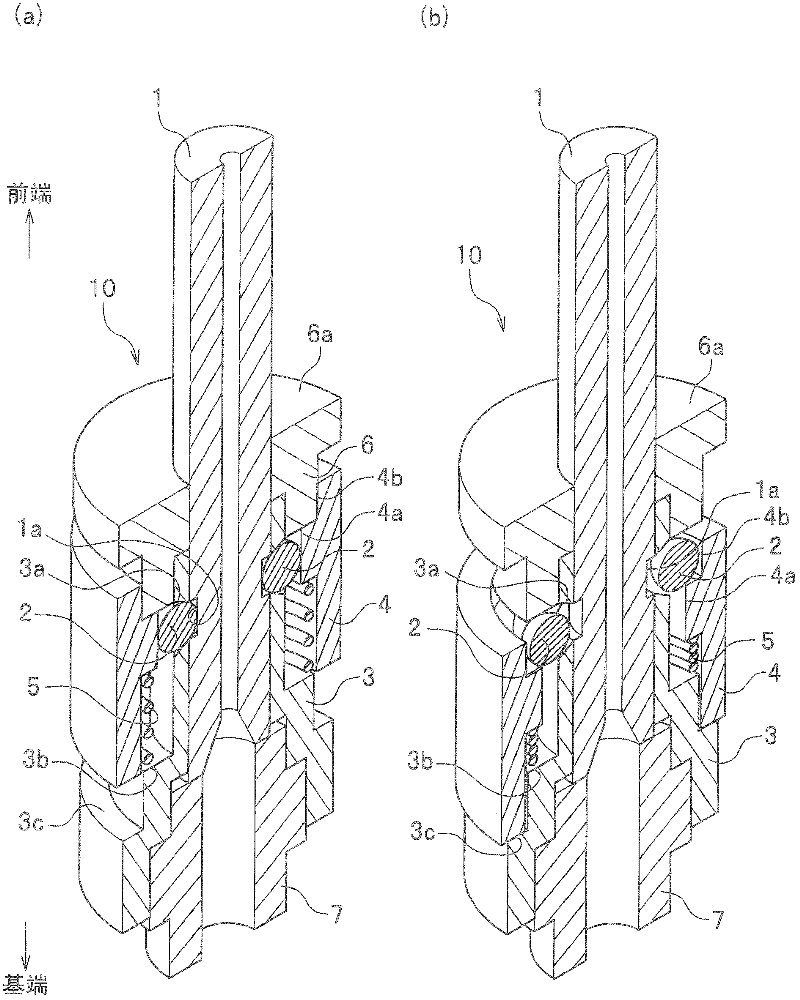

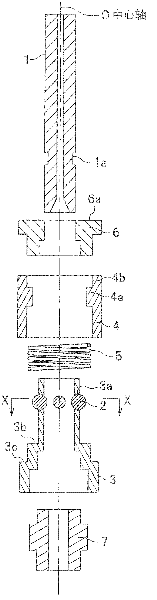

[0117] The welding torch of embodiment is as figure 1 As shown, it consists of a welding tip forming a fixing groove, a welding tip connecting body forming a fixing hole, a holding member forming a diameter-reducing part and a diameter-expanding part, an elastic member, a spherical fixing member, a ring-shaped sealing member and Connection components.

[0118] On the other hand, the welding torch of the comparative example is composed of a welding tip having an external thread formed on the outer peripheral surface of the base end portion and a tip connecting body having an internal thread formed on the inner periphera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com