Rattan weaving machine

A rattan weaving machine and rattan weaving technology, applied in mechanical equipment, sugarcane machining, etc., can solve the problems of cumbersome manual rattan pulling operation, low work efficiency, unsafe operation, etc., and achieve improved rattan weaving efficiency and quality, and simple structure , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

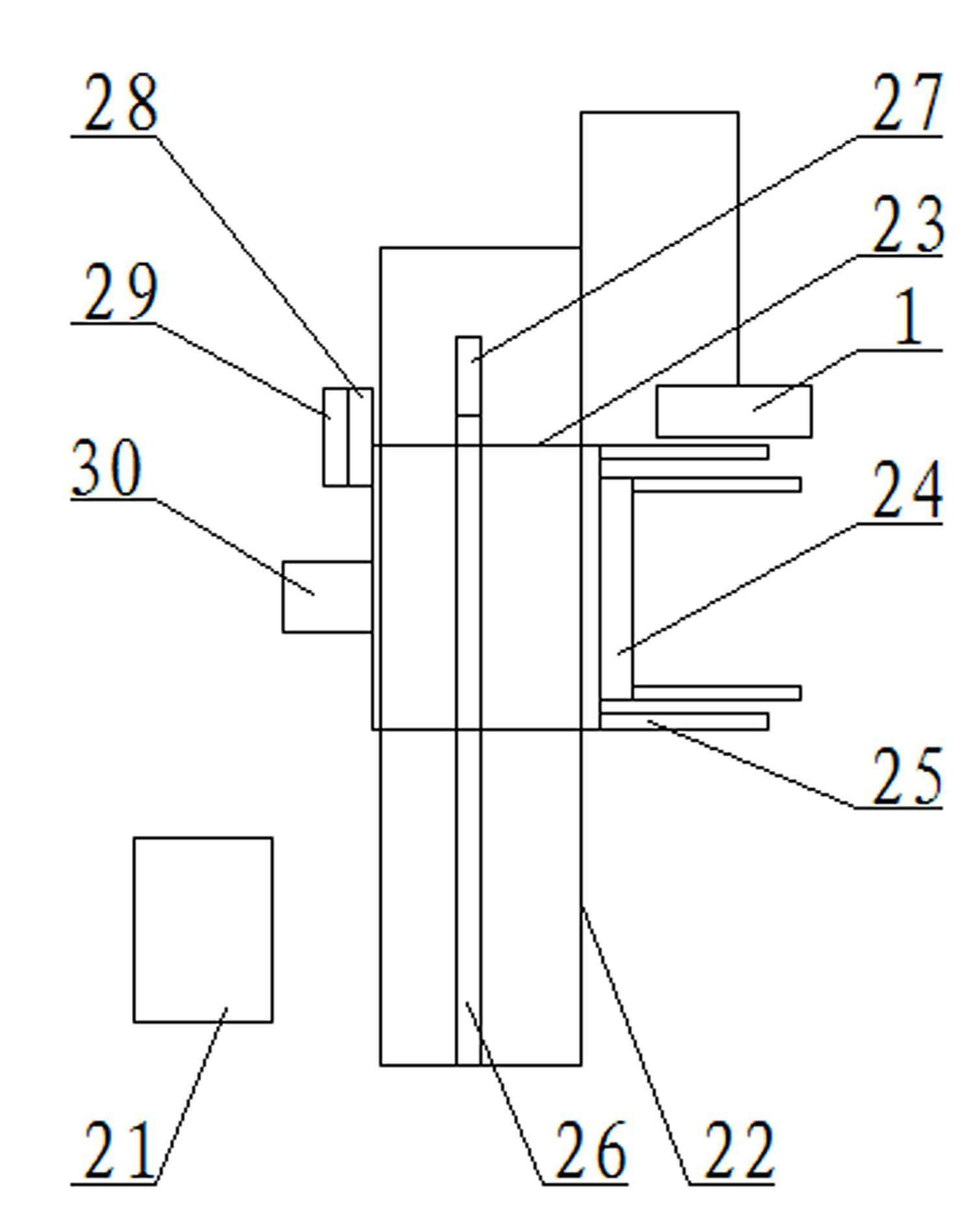

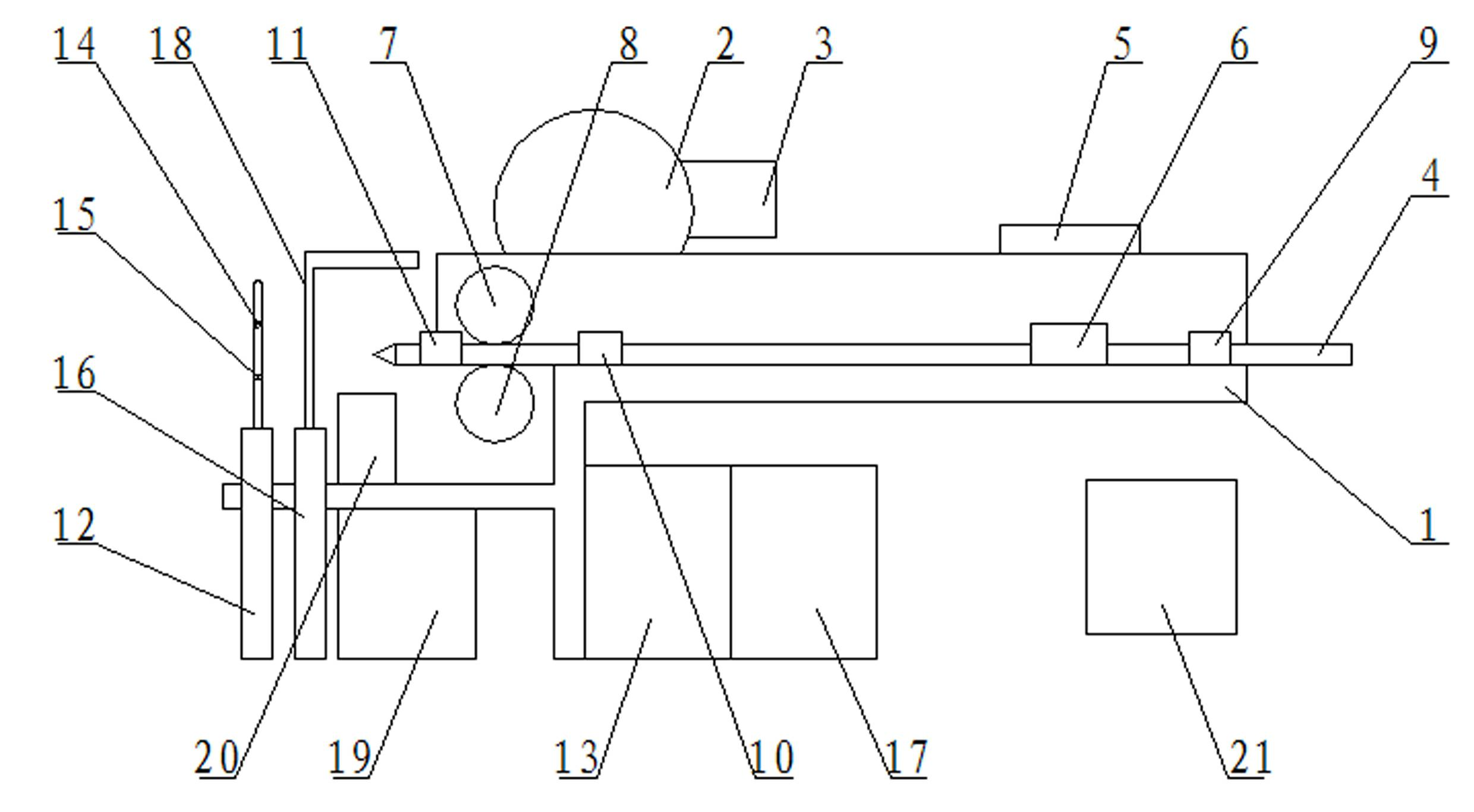

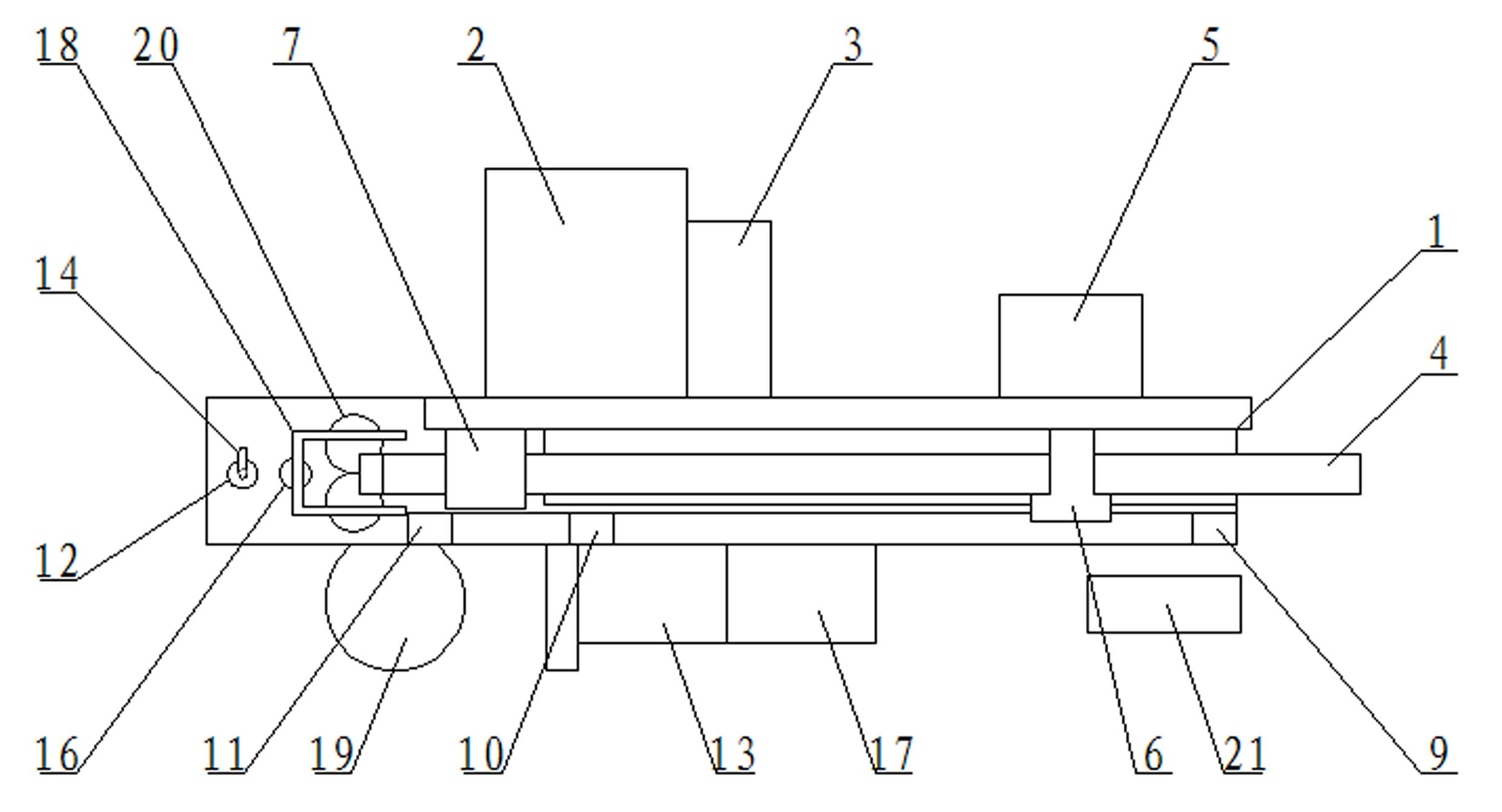

[0028] Figure 1-2As shown, a kind of rattan weaving machine comprises frame 22, supporting plate 23, rotating panel 24, supporting connecting rod 25, lifting cylinder 26, pulley 27, lifting relay 28, rotating relay 29, rotating motor 30, shuttle frame 1, Main motor 2, reversing relay 3, rattan shuttle 4, clamping cylinder 5, chuck 6, upper pressure wheel 7, lower pressure wheel 8, reverse stroke switch 9, forward stroke switch 10, shuttle head reversing sensor 11 , reversing cylinder 12, reversing solenoid valve 13, upper blowing head 14, lower blowing port 15, rattan pressing cylinder 16, rattan pressing solenoid valve 17, rattan pressing device 18, auxiliary motor 19, rattan roller group 20 and controller twenty one. The lifting cylinder 26 is vertically arranged on the frame 22 by the pulley 27 through the steel wire to support the support plate 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com