Two-stage pressing manhole device

A compression-type, manhole cover technology, applied to underwater structures, buildings, infrastructure engineering, etc., can solve problems such as complex process, material leakage, insufficient strength reserve, etc., to simplify the manufacturing process, reduce labor intensity, The effect of improving structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

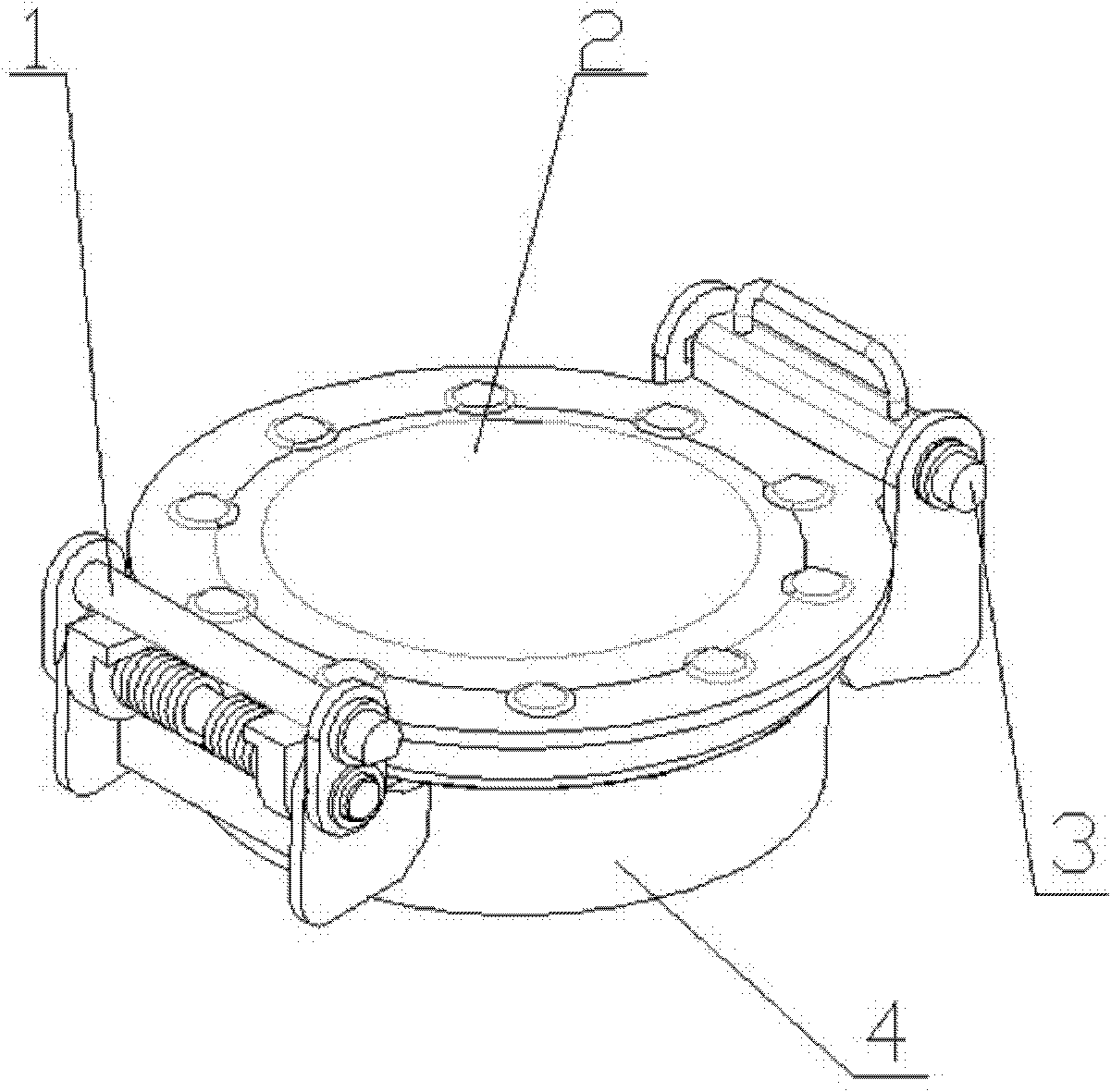

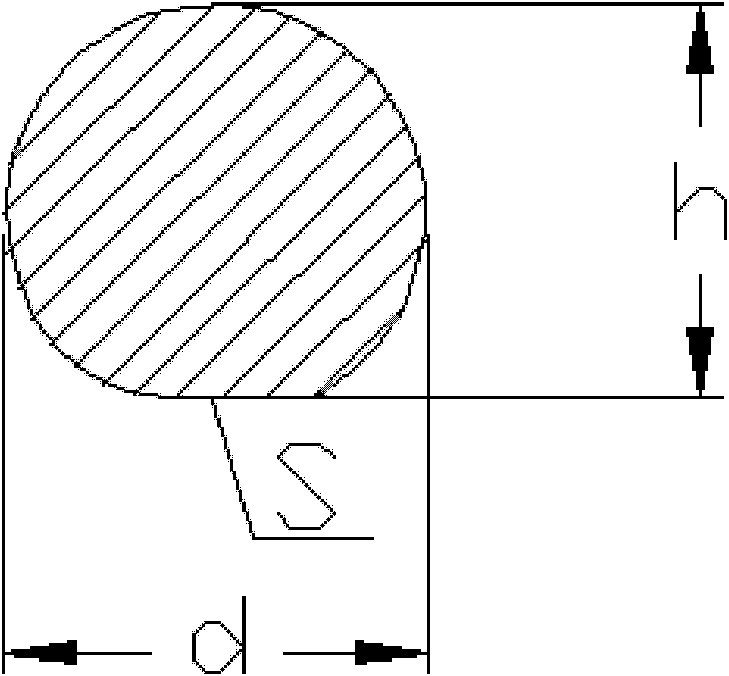

[0032] refer to figure 1 , Figure 4 and Figure 8 , A two-stage compression manhole device provided by the embodiment of the present invention is mainly assembled by a compression device 1 , a manhole cover device 2 , a locking pin device 3 and a manhole seat device 4 . The manhole seat device 4 includes a retaining ring 7 , a rotating shaft 8 , ribs 9 and pressing lugs 10 . The manhole cover 11 is hinged to the manhole cover device 2 through the rotating shaft 8 , and the locking pin device 3 is connected through the manhole cover 11 and the pressing ear plate 10 .

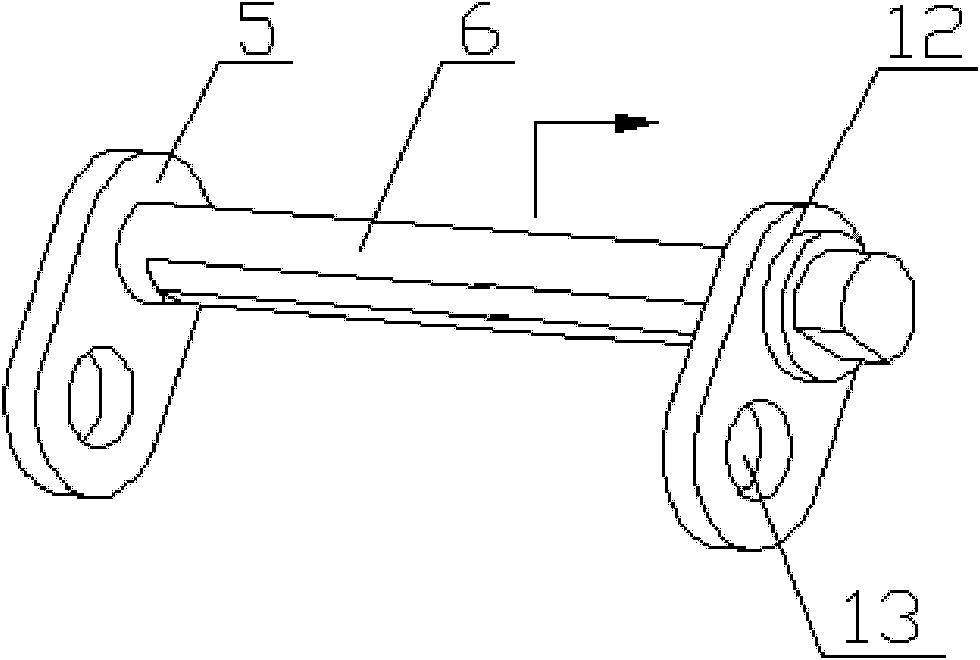

[0033] refer to Figure 1 to Figure 3 , The pressing device 1 is mainly made up of the finale connecting plate 5 and the finale 6, the finale 6 passes through the upper shaft hole 12 of the finale connecting plate 5, and the rotating shaft 8 passes through the lower shaft hole 13 and the retaining ring 7 of the finale connecting plate 5. Finale 6 can rotate in the finale connecting plate 5 . The final shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com